Preparation for r-Li ALO2 single-crystal thin-film covering layer substrate by pulsing laser deposition

A technology of pulsed laser deposition and single crystal thin film, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of waste of raw materials, difficulty in obtaining large size, difficulty in crystal growth, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh a certain amount of LiOH and Al 2 o 3 (molar ratio 2:1) put it into a reaction vessel, heat it in an air atmosphere and keep the temperature at 600°C, and fully react for 1.5h (above) to obtain γ-LiAlO 2 . Then γ-LiAlO 2 The powder is pressed into a target;

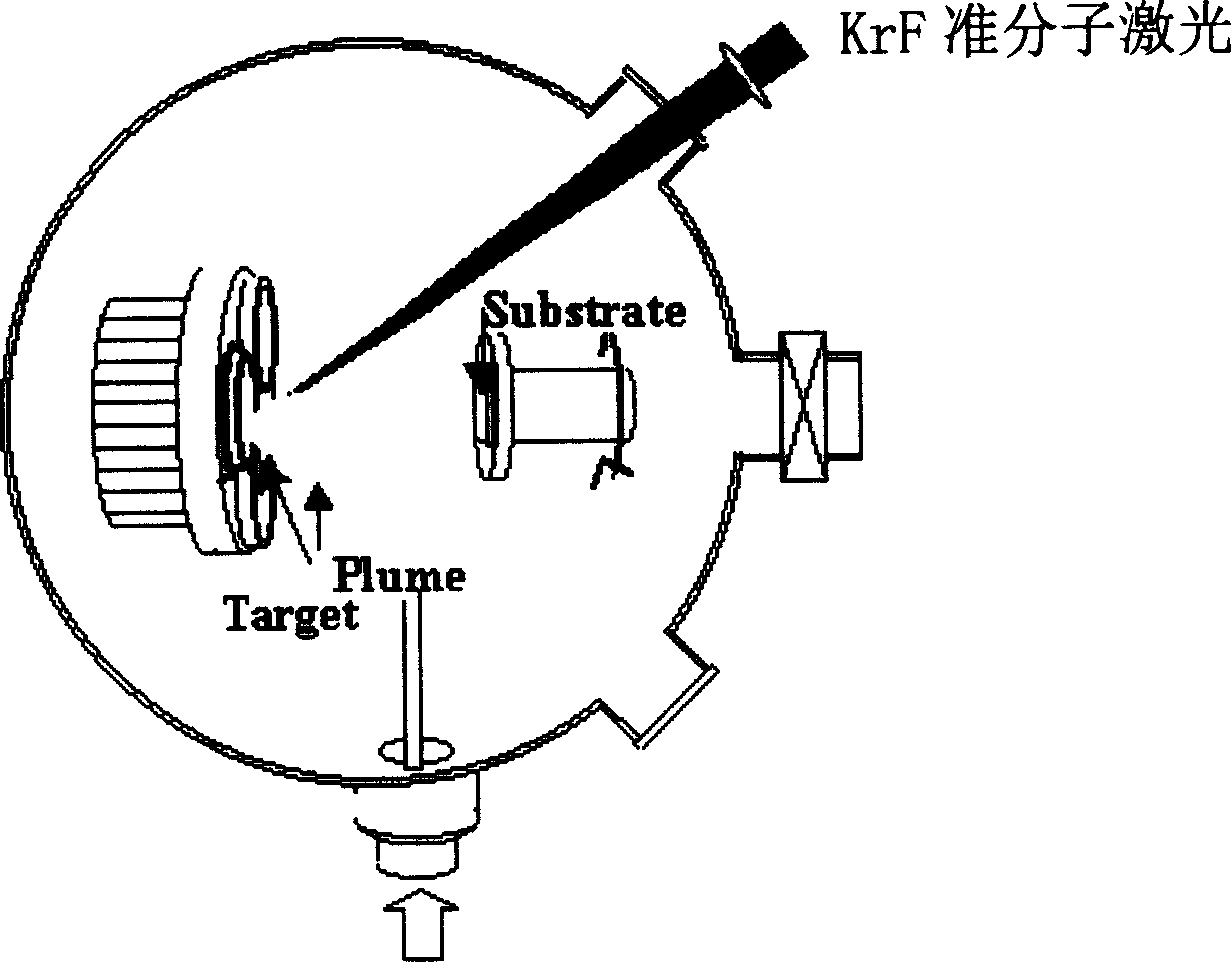

[0026] α-Al to be cleaned 2 o 3 Or silicon substrate and γ-LiAlO 2 The target material is sent into the pulsed laser deposition device;

[0027] Evacuate the cavity into a high vacuum (> 10 -4 Pa), then filled with argon atmosphere;

[0028] Heat the substrate to 500°C, and pass the KrF excimer laser with a pulse width of 25ns through the lens at 10J / cm 2 Concentrate light with an energy density of 1000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000, through the optical window to γ-LiAlO in the device 2 The target material, the surfa...

Embodiment 2

[0030] Weigh a certain amount of LiOH and Al 2 o 3 (molar ratio 2:1) put it into a reaction vessel, heat it in an air atmosphere and keep the temperature at 500°C for a full reaction of 1.5h (above) to obtain γ-LiAlO 2 . Then γ-LiAlO 2 The powder is pressed into a target;

[0031] α-Al to be cleaned 2 o 3 Or silicon substrate and γ-LiAlO 2 The target material is sent into the pulsed laser deposition device;

[0032] Evacuate the cavity into a high vacuum (> 10 -4 Pa), then filled with argon atmosphere;

[0033] Heat the substrate to 600°C, and pass the KrF excimer laser with a pulse width of 25ns through the lens at 10J / cm 2 Concentrate light with an energy density of 1000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000, through the optical window to γ-LiAlO in the device 2 The target material, the surfa...

Embodiment 3

[0035] Weigh a certain amount of LiOH and Al 2 o 3 (molar ratio 2:1) put it into a reaction vessel, heat it in the air atmosphere and keep the temperature at 600°C for a full reaction of 1.5h (above) to obtain γ-LiAlO 2 . Then γ-LiAlO 2 The powder is pressed into a target;

[0036] α-Al to be cleaned 2 o 3 Or silicon substrate and γ-LiAlO 2 The target material is sent into the pulsed laser deposition device;

[0037] Evacuate the cavity into a high vacuum (> 10 -4 Pa), then filled with argon atmosphere;

[0038] Heating the substrate to 900°C, focusing the KrF excimer laser with a certain energy density through the lens, and irradiating the γ-LiAlO in the device through the optical window 2 The target material, the surface layer molecules of the target material are melted and vaporized to form a film on the substrate, and the γ-LiAlO can be obtained after slow cooling 2 single crystal film.

[0039] Experiments show that the method of the invention has simple pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com