Vortex flowmeter including pressure pulsation amplitude analysis

A vortex flowmeter and vortex technology, applied in the field of vortex flowmeter, can solve the problems of inaccurate flow measurement value of vortex flowmeter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

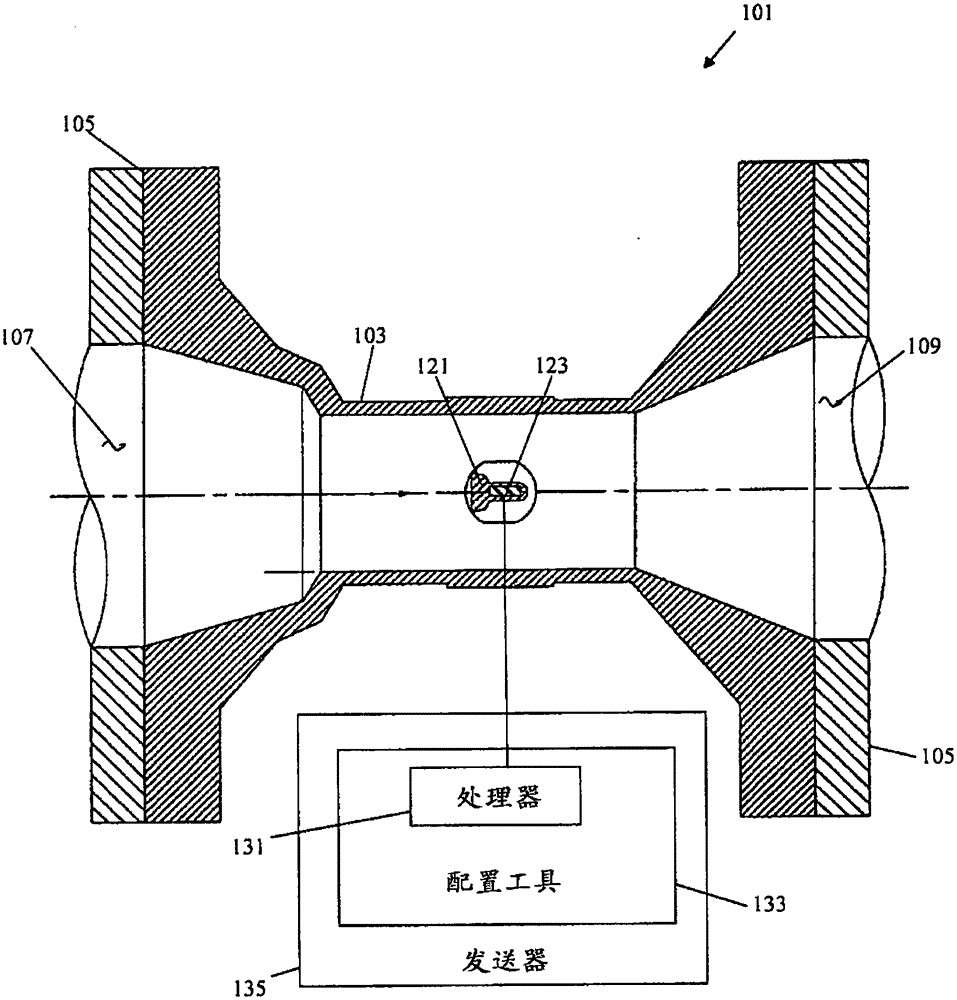

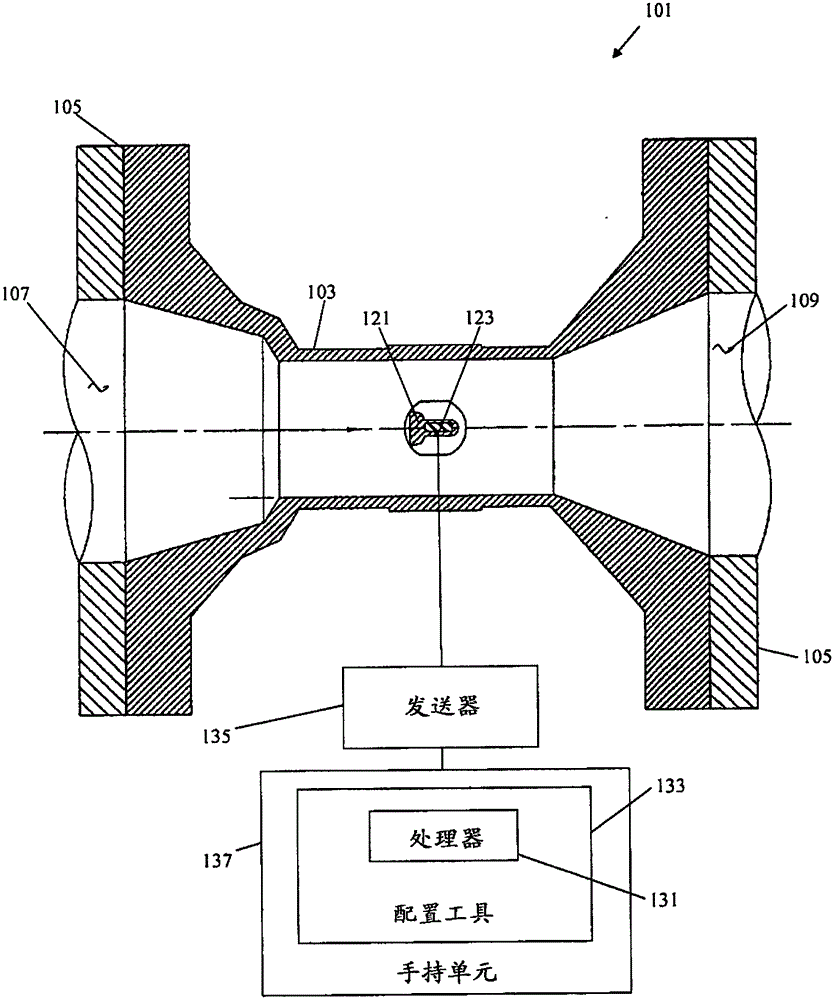

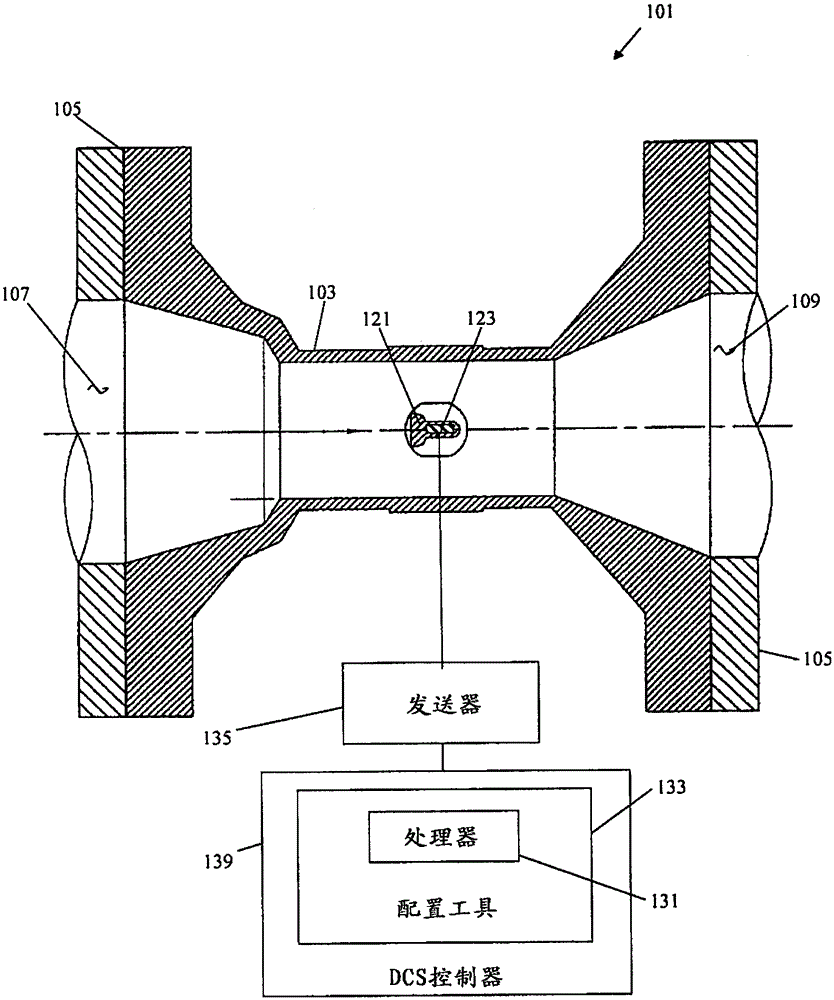

[0019] Referring now to the drawings, first to the attached figure 1 , one embodiment of a vortex flowmeter for measuring fluid velocity, generally designated 101. The vortex flowmeter 101 includes a flow conduit 103 through which fluid flows. Flow conduit 103 is suitably configured to fit within a fluid flow line (not shown). For example, process connections 105 (eg, flanges) are located on opposite ends of the flow conduit 103 for connecting the inlet 107 and outlet 109 of the flow conduit to the respective conduit ends of the pipeline. It is also common in the industry to use so-called wafer connections, so that the flowmeter is installed in the fluid line, and the flow line is adapted to the wafer connection (or any other type of connection, if desired). pieces).

[0020] A bluff body 121 (sometimes referred to in the industry as a swirl remover or strip) is located in the flow conduit 103 . The bluff body 121 is a structure that partially blocks the flow of fluid thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com