Hyperbaric cabin device for external pressure test of pressure container model

A pressure vessel and external pressure test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of watertight joints that are easily damaged, easy to leak, and the sensor is easy to damage the test cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further illustrate the present invention below in conjunction with accompanying drawing.

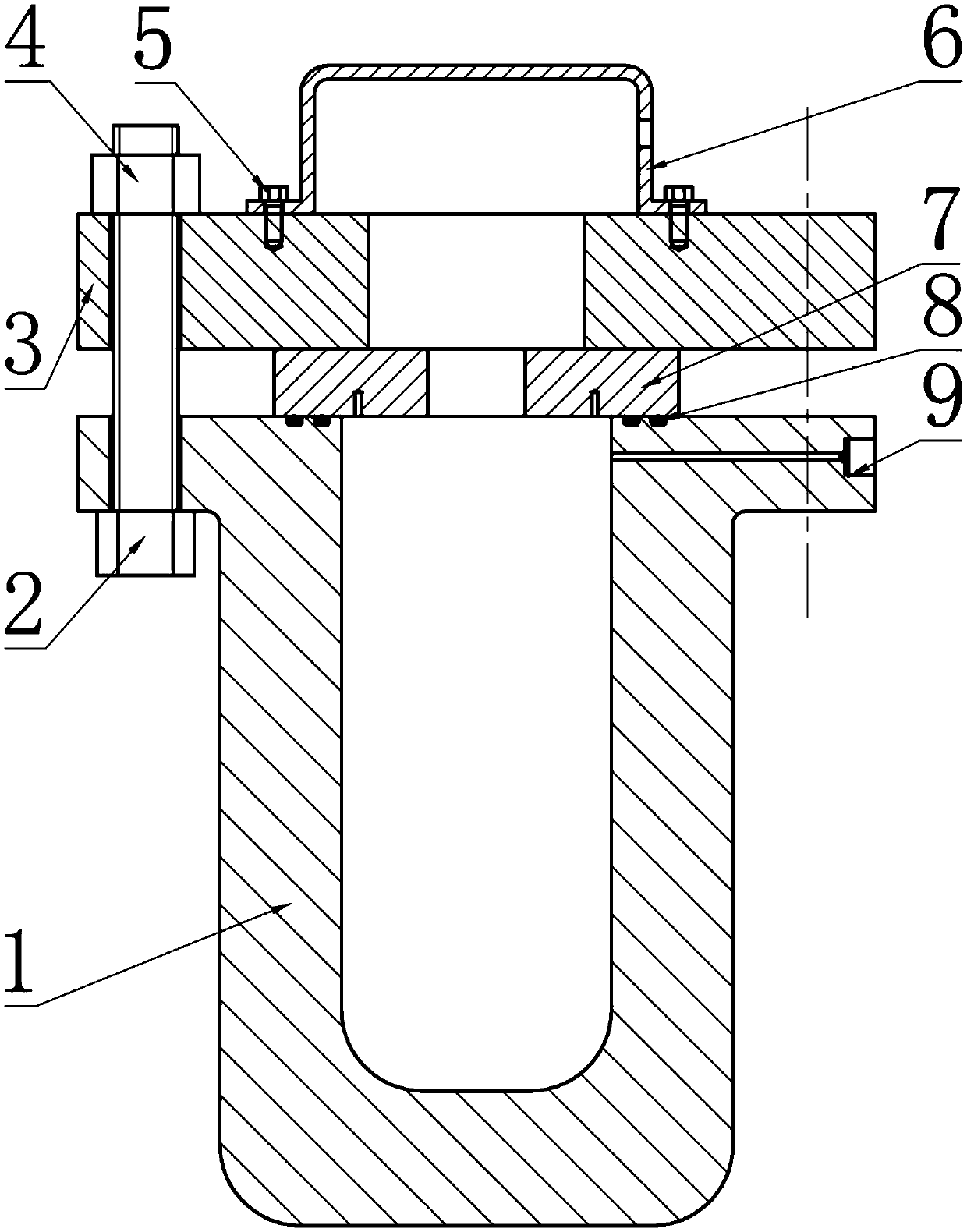

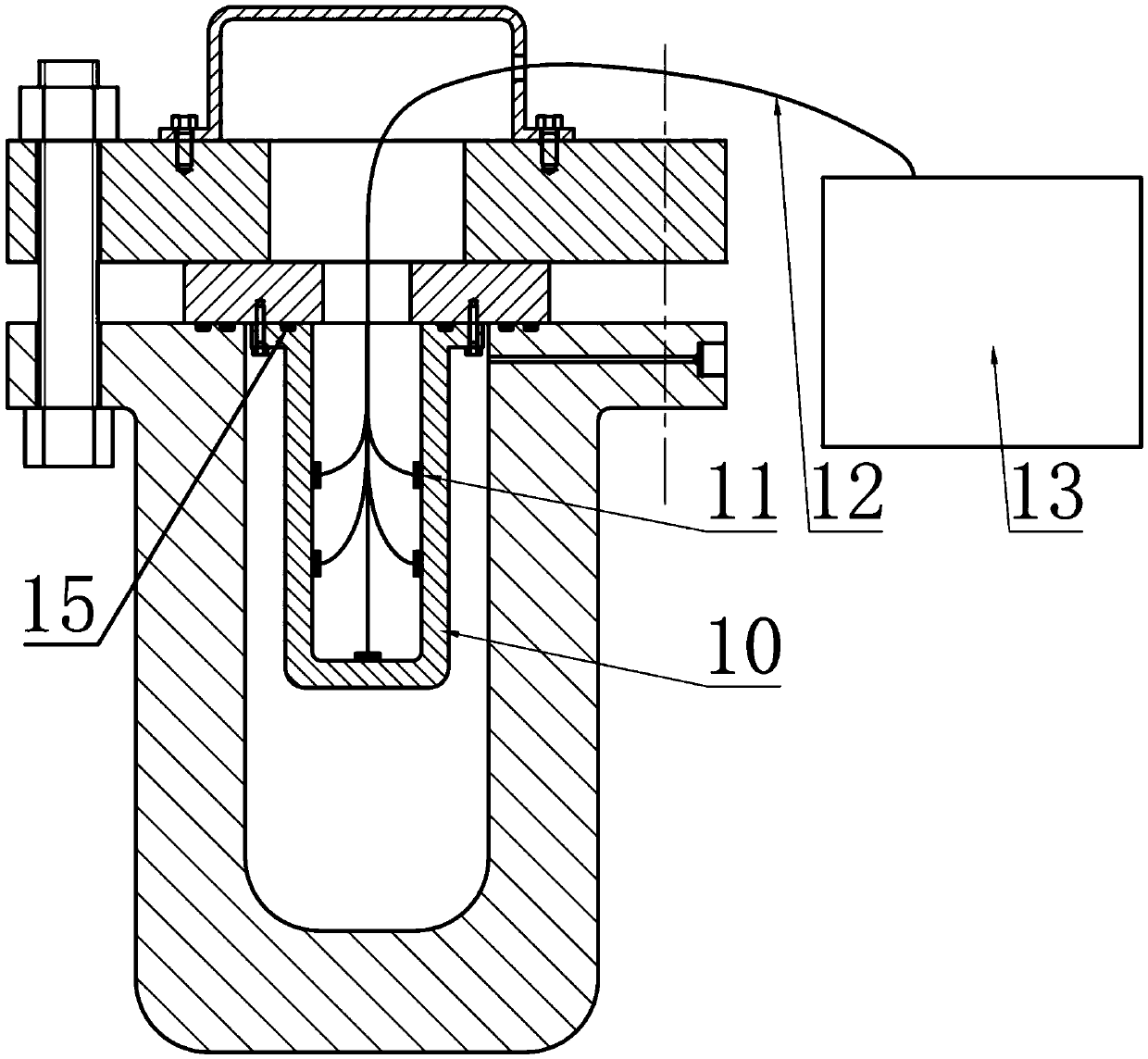

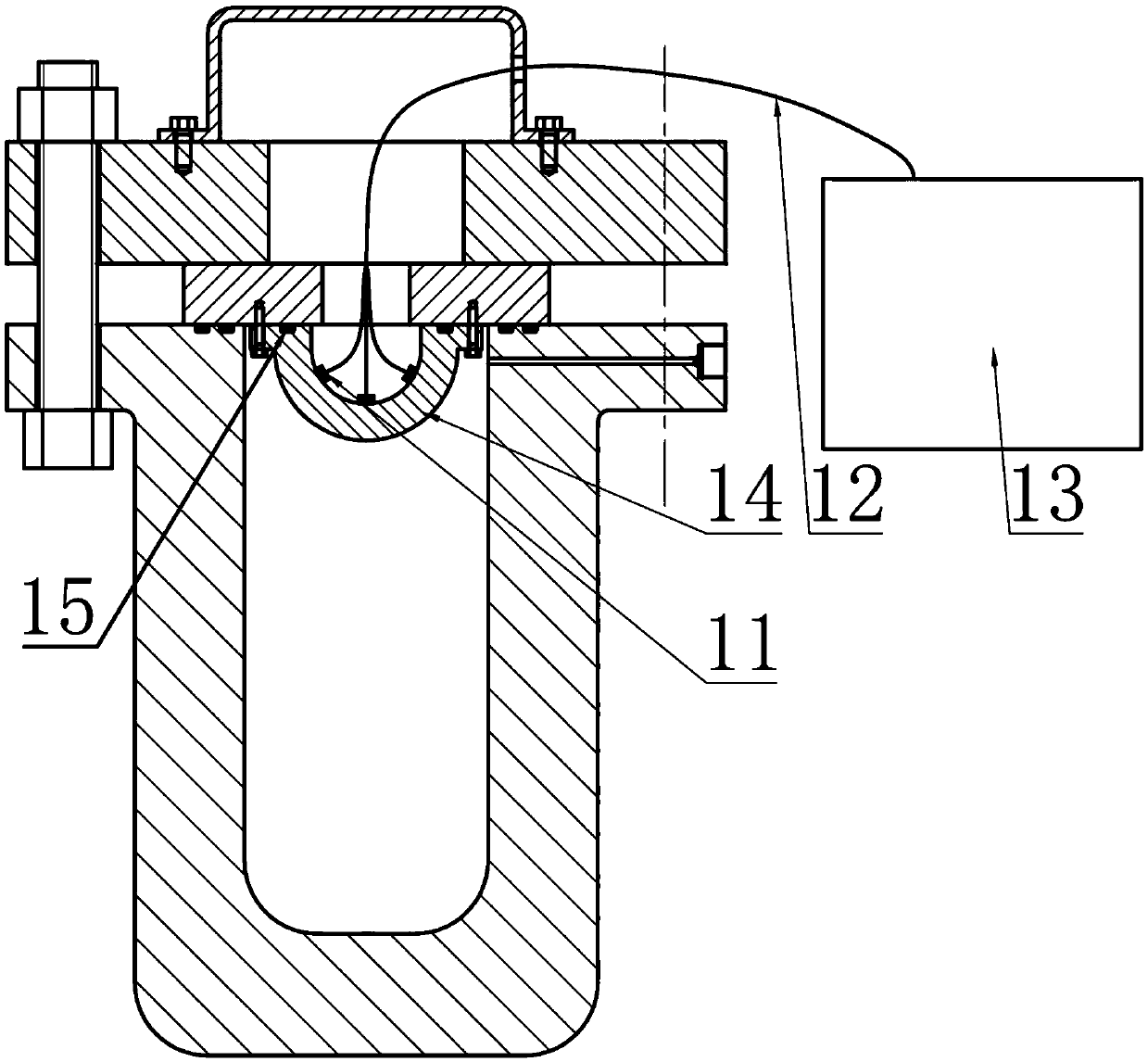

[0012] refer to figure 1 , a kind of hyperbaric chamber device that is used for the pressure vessel model external pressure test of the present invention, it comprises: hyperbaric chamber tank cylinder 1, hyperbaric chamber hatch cover 3, a plurality of fixing bolts 2 nuts 4, a plurality of protective cover fixing bolts 5, Protective cover 6, pressure vessel fixing plate 7, two sealing O-rings 8 and pressure transfer interface 9; the side wall of the flange plate of hyperbaric cabin tube 1 is provided with pressure transfer interface 9, and the flange plate of hyperbaric cabin tube 1 is opened There are a plurality of equally spaced bolt holes, the flange of the hyperbaric cabin cover 3 has a plurality of equally spaced bolt holes, and the upper end surface of the hyperbaric cabin tank 1 is provided with two axial static sealing O-ring grooves, Two sealing O-rings 8 are axially i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com