Aero-engine maintenance engineering management tool

A technology of aero-engine and maintenance engineering, applied in the direction of instruments, etc., can solve problems such as difficult quality control, high price, long procurement cycle, etc., and achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

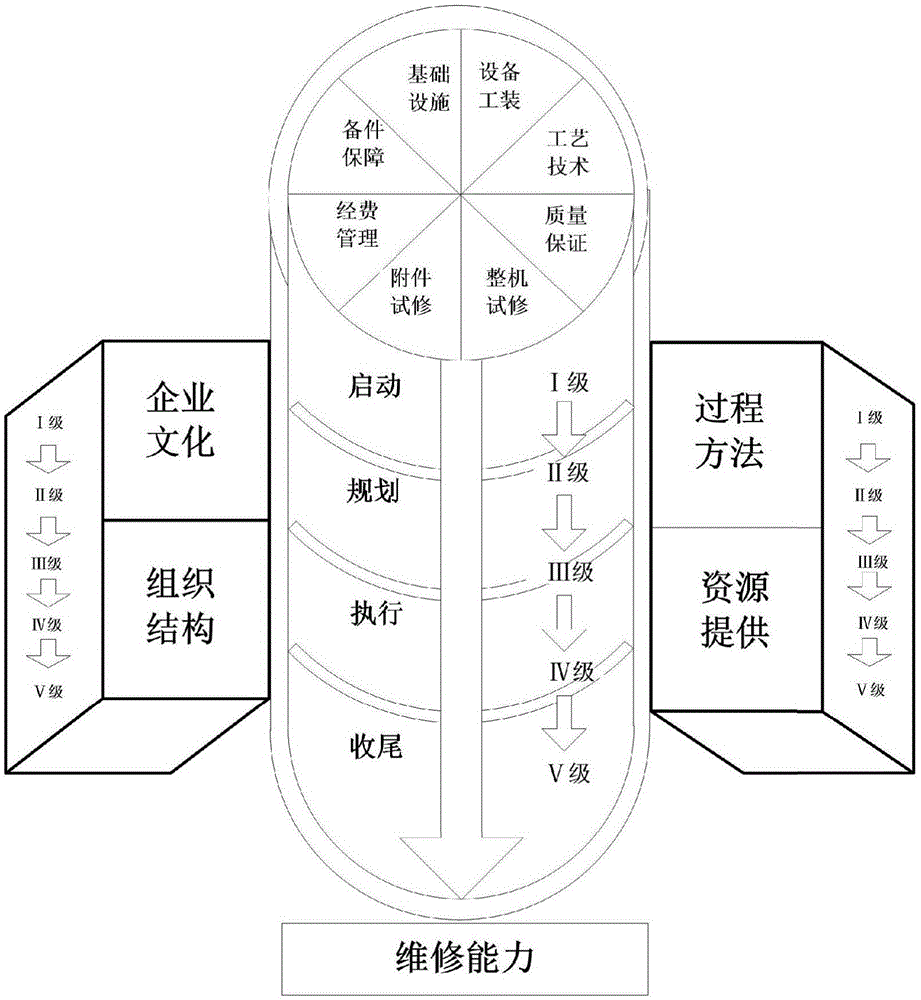

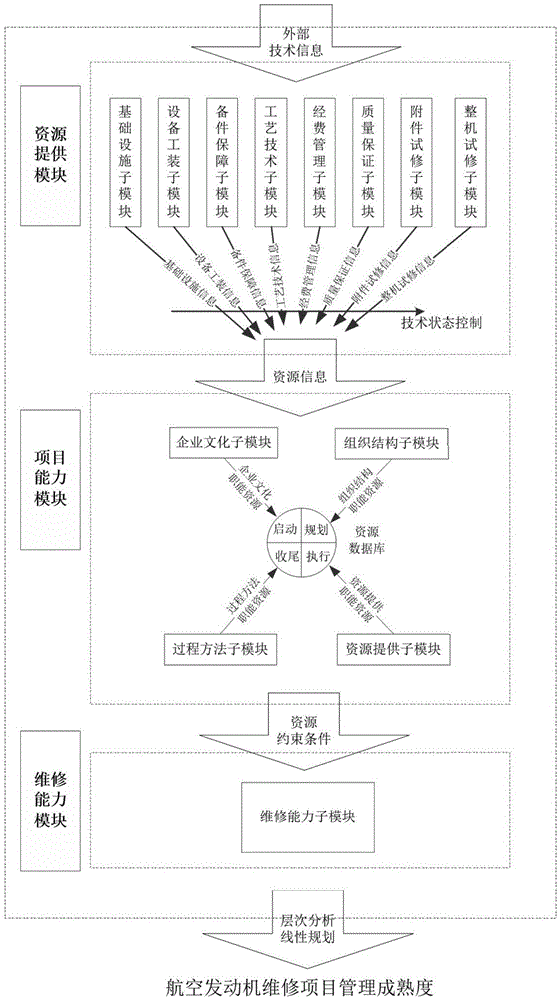

[0022] refer to figure 1 . In the embodiment described below, an aero-engine maintenance engineering management tool includes a project capability module for building an aero-engine maintenance engineering management platform, a resource provision module, a maintenance capability module, and a full-field, comprehensive Process line building process management, resource supply module establishment and industrial chain upstream and downstream technology information transmission platform, timely and accurate transmission of the realization of technical status, project capability module according to the information provided by the resource supply module, set up mobilizable technology, quality, production, and infrastructure Relevant functional resources of facilities and human resources, collect input information of repair line construction, establish resource database, provide necessary information on equipment development, use, and failure, organize flexible and dynamic manageme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com