AC/DC power supply transfer box and comprehensive automation transformation method

A technology of AC and DC power supply and transfer box, which is applied in the direction of electrical components, substation/switch layout details, busbar/line layout, etc., which can solve the problems of increasing construction workload, reducing construction efficiency, and reducing power supply reliability, etc. The number of equipment power outages, the reduction of repetitive labor, and the effect of optimizing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

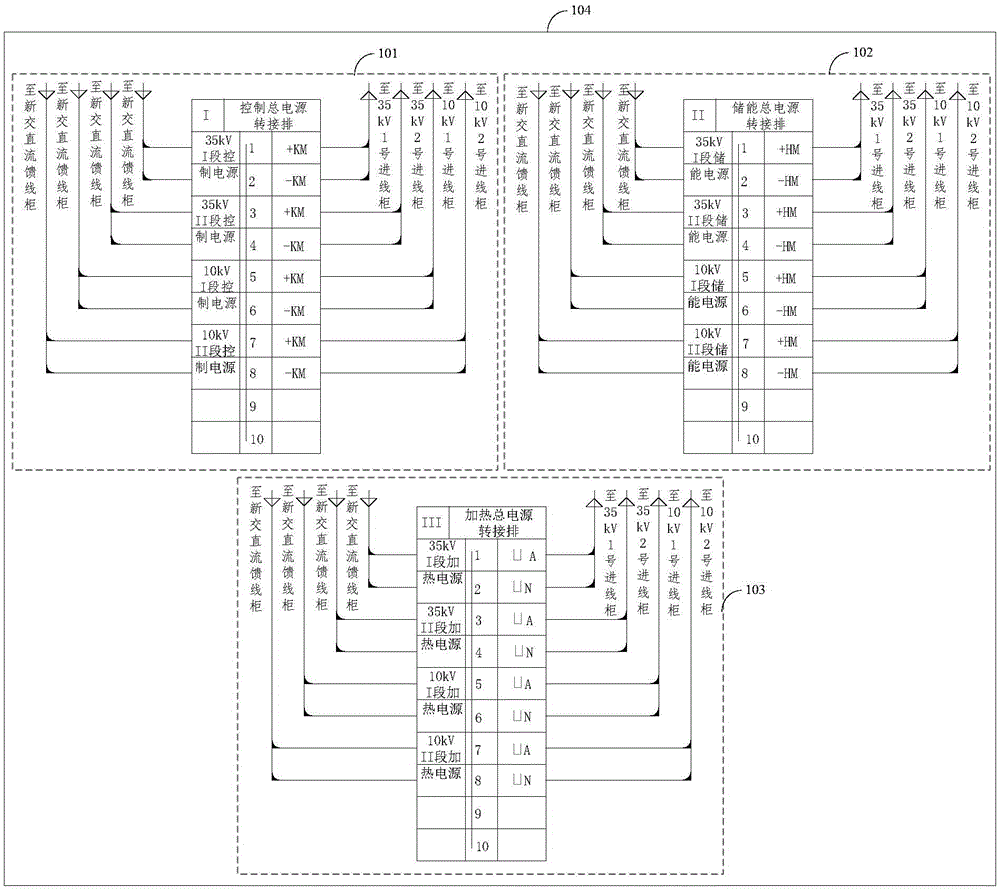

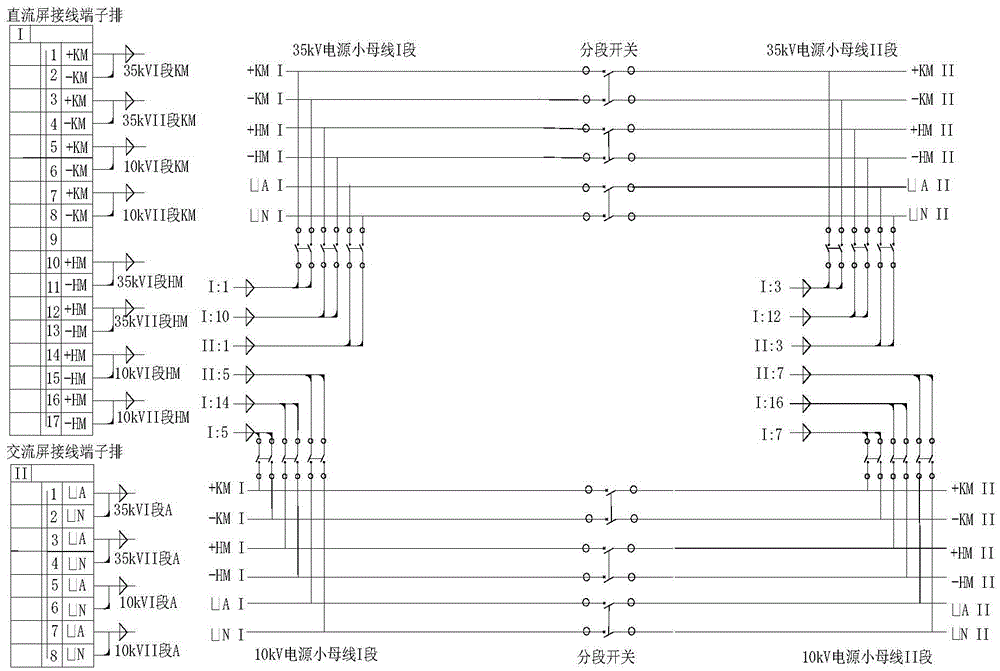

[0037] This embodiment provides an AC-DC power transfer box, such as figure 1 shown, including:

[0038] The total control power transfer part 101 includes a multi-channel control power inlet interface, a multi-channel control power outlet interface, and a first terminal block for connecting the multi-channel control power inlet interface and the multi-channel control power outlet interface. A transfer interface is provided between the incoming cable of the small bus bar of the control main power supply on the top of the switch cabinet and the outgoing cable of the control power supply of the integrated power panel. Preferably, as figure 1 As shown, the total control power transfer part 101 includes 4 control power inlet interfaces, 4 control power outlet interfaces, and the first terminal block for connecting the 4 control power inlet interfaces and the 4 control power outlet interfaces (that is, control the main power adapter).

[0039] Preferably, as figure 1 As show...

Embodiment 2

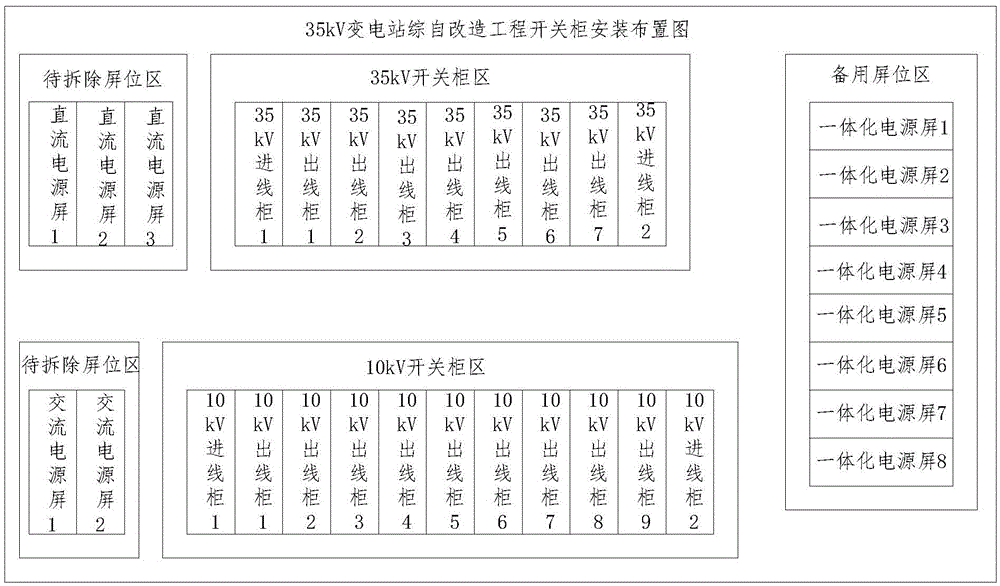

[0047] This embodiment provides a comprehensive self-retrofitting method, for example, the AC-DC power transfer box in the above-mentioned embodiment 1 can be used, such as Figure 5 As shown, the comprehensive self-reform method includes the following steps:

[0048] S1. Install the integrated power screen;

[0049] S2, laying power cables;

[0050] S3, using the AC-DC power transfer box to perform AC-DC power transfer;

[0051] S4. Remove the original AC and DC power screen;

[0052] S5, install the protection measurement and control screen;

[0053] S6. Laying protection, measurement and control cables to each switch cabinet;

[0054] S7. Control each switch cabinet to power off in sequence;

[0055] S8, connect to the power supply, protect the new cable for measurement and control;

[0056] S9, test;

[0057] S10. After the test is successful, restore the power supply.

[0058] In the comprehensive self-renovation project of the substation, the construction flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com