Device and method for treating poor contact heating electricity of equipment wiring board and jumper conductor clamper

A technology for poor contact and live treatment, which is applied to contact parts, clip connection conductor connections, circuit/collector parts, etc. , Unable to eliminate problems such as heating defects of equipment wiring boards, to achieve the effect of improving current capacity, eliminating heating defects, and eliminating equipment heating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

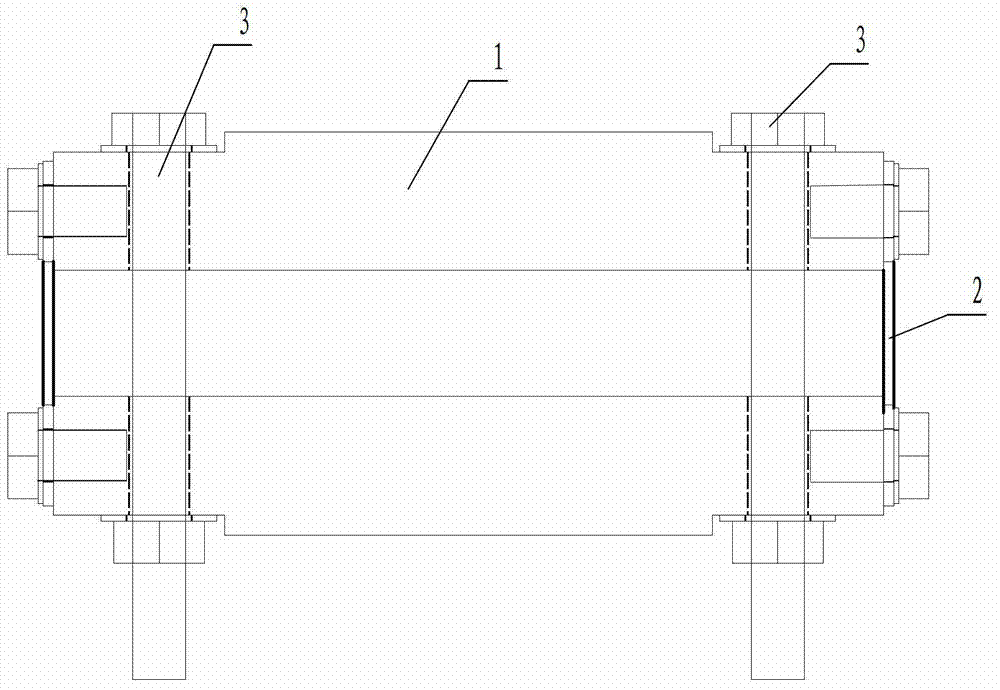

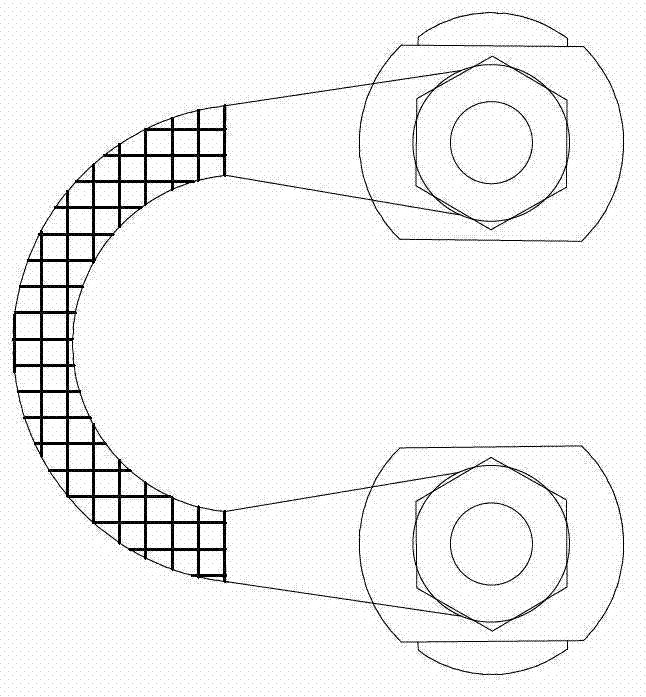

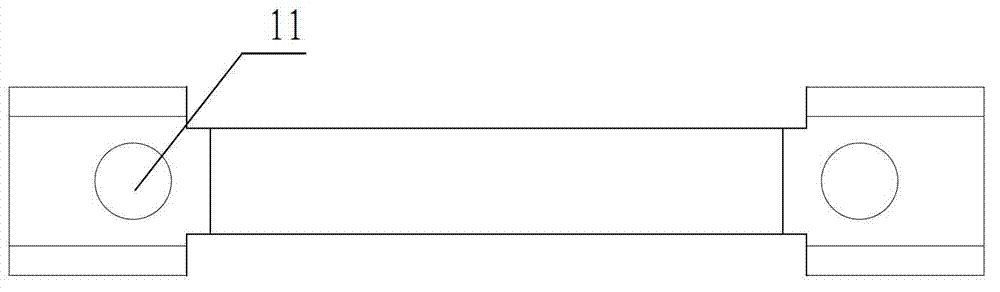

[0030] a kind of like Figure 1-4 The shown equipment wiring board and the drain line clip are in poor contact with the heating and heating treatment device, which includes two guide bodies 1 and two guide lines 2, and the two guide lines are respectively detachably connected to the two guide bodies. At both ends, the two diversion lines respectively communicate with the two diversion bodies, and the two ends of the inner sides of the diversion lines on the two diversion bodies are also provided with through holes 11 through the upper and lower sides of the two diversion bodies, and the two diversion bodies use this through hole Use connector 3 to connect together. The connecting piece is a flow-guiding bolt. The movable and detachable connection between the guide wire and the two guide bodies is that the two ends of the two guide bodies are provided with threaded blind holes extending along the length direction of the guide body, and the guide wire is connected to the thread...

Embodiment 2

[0033] A heat treatment method for poor contact between the equipment terminal board and the drain wire clamp, the steps are as follows: set two guide bodies on the upper and lower sides of the middle of the equipment terminal board and the drain wire clamp fixing bolts respectively, and then use the connector to lock the Tighten the two diversion bodies, and at the same time connect the diversion wires to the two ends of the two diversion bodies to communicate with the two diversion bodies.

[0034] The parts not described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com