Special tool for power-cut or live replacement of 220kV spacer

A special tool and live replacement technology, applied in the field of electric power, can solve problems such as difficulty in completion, low success rate, and high physical energy consumption of operators, and achieve the effects of enhancing safety, standardizing maintenance operations, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

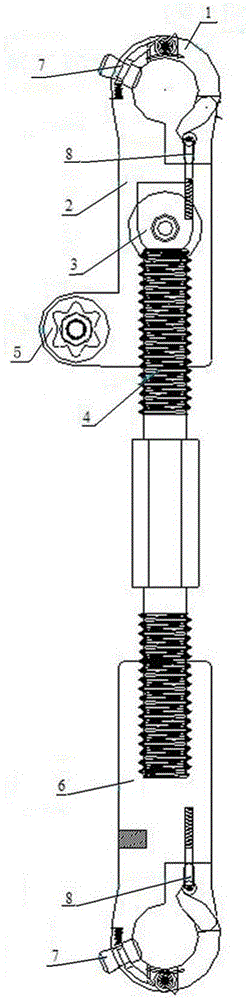

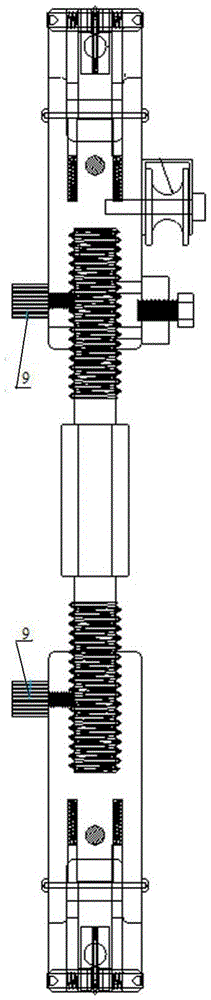

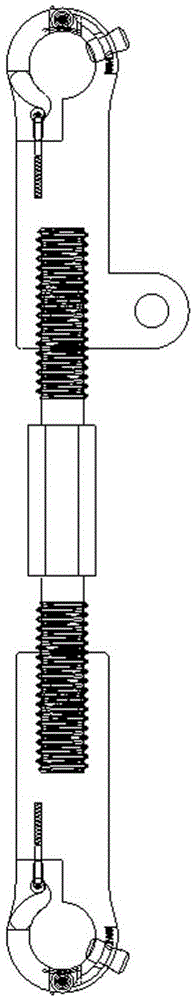

[0016] See Figure 1-Figure 6 , a special tool for replacing a 220kV spacer in a power failure or live, is characterized in that it includes an upper hook 2 and a lower hook 6, and the upper and lower hooks are threadedly connected by a labor-saving screw rod 4 respectively; the upper hook 2 1. The hook ends of the lower hook 6 are respectively connected with a trigger locking hook 1. After the trigger device 7 is triggered, the locking device 8 locks the trigger locking hook 1, so that the upper hook 2 and the lower hook 6 are respectively closed with the trigger locking hook 1. A round structure is formed; a pulley 3 is fixedly connected to one side of the upper hook 2, and an insulating operating rod connector 5 is fixedly connected to one side of the lower hook 6, and the screw rod is fixed by a screw locking device 9.

[0017] 1. Design principle

[0018] During live work, if the operator at the lower sub-conductor wants to pull back the upper sub-conductor, he can only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com