Pivoting fitting

A technology of pivoting and pivoting movement, which is applied in the directions of pivot connection, transportation and packaging, and the special position of the vehicle, which can solve the problems of large locking noise and troubles, and achieve the reduction of locking noise, reduction of noise development, Effect of Ensuring Functional Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

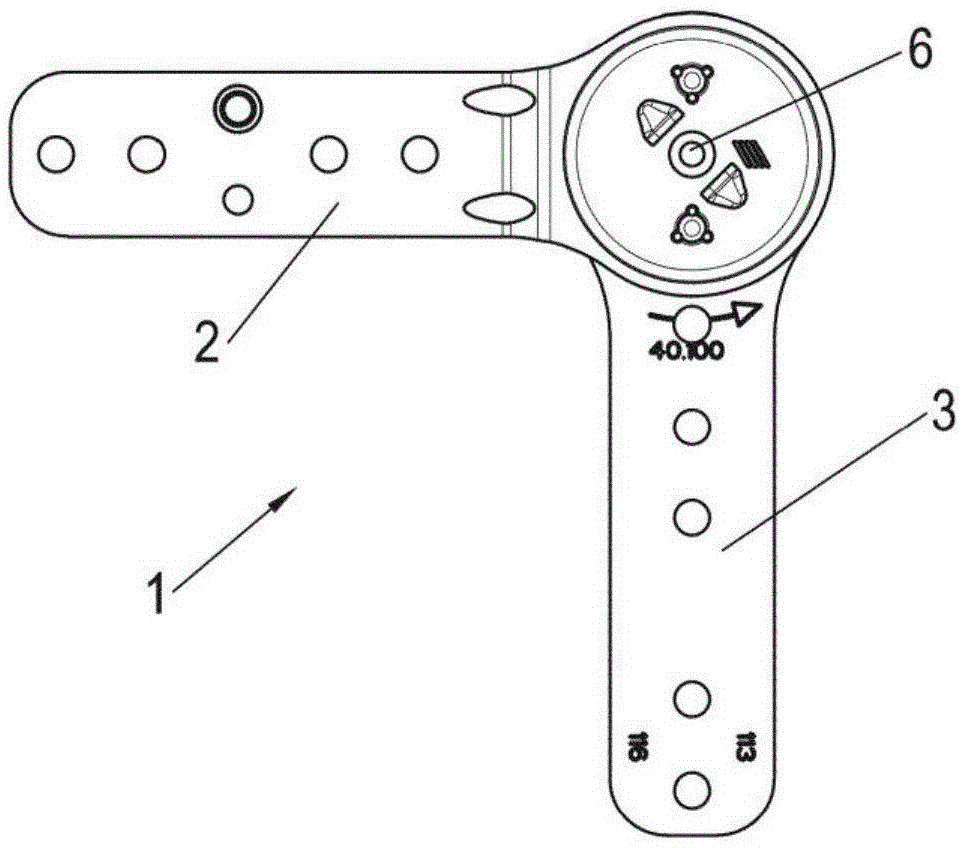

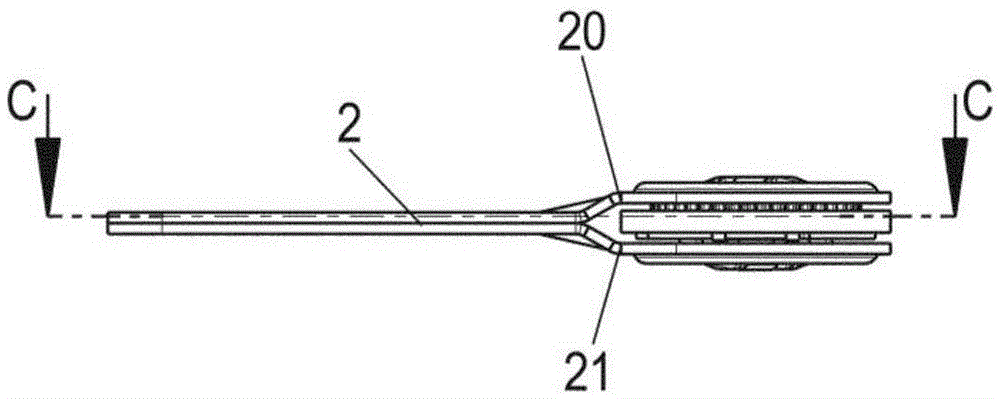

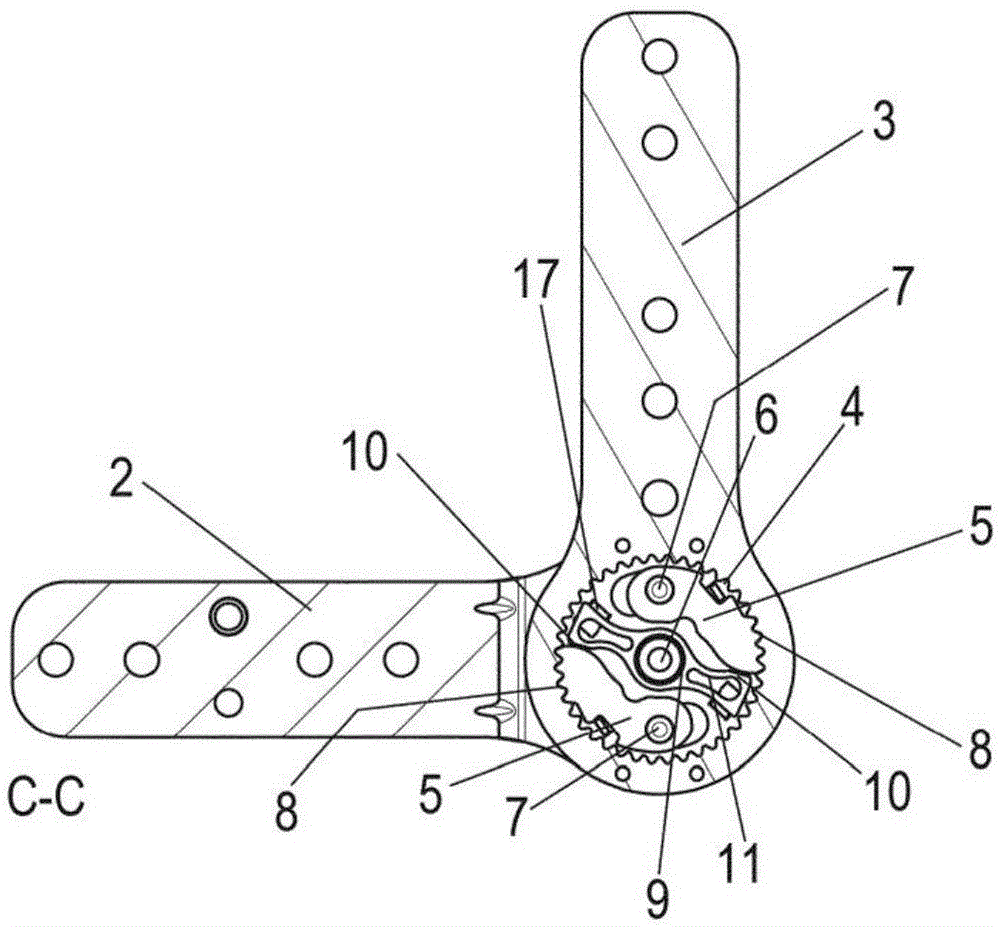

[0020] The pivoting device 1 comprises a first sheet assembly 2 and a second sheet assembly 3 which are pivotable relative to each other about an axis 6 . The first blade pack 2 comprises a first part 20 and a second part 21 which are connected to each other on a portion projecting radially from the shaft 6 and surround the central region of the second blade pack 3 in the region of the shaft 6 . In the intermediate area between the first part 20 and the second part 21 there is provided a locking or locking mechanism which allows movement of the first sheet assembly 2 relative to the second sheet assembly 3 in a first direction and in a second limited in direction. The restraint is disengaged in the end position and the sheet assemblies 2 and 3 can be moved back to the initial position.

[0021] like Figure 1C As shown, the locking mechanism comprises two pawls 5 mounted for rotation about an axis 7 . Two shafts 7 are provided spaced apart from the central shaft 6 for pivot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com