Seal cover, bearing unit, and axle box device

A technology of sealing cover and bearing, applied in the field of bogies, can solve problems such as breakage of stop pins and failure of anti-rotation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

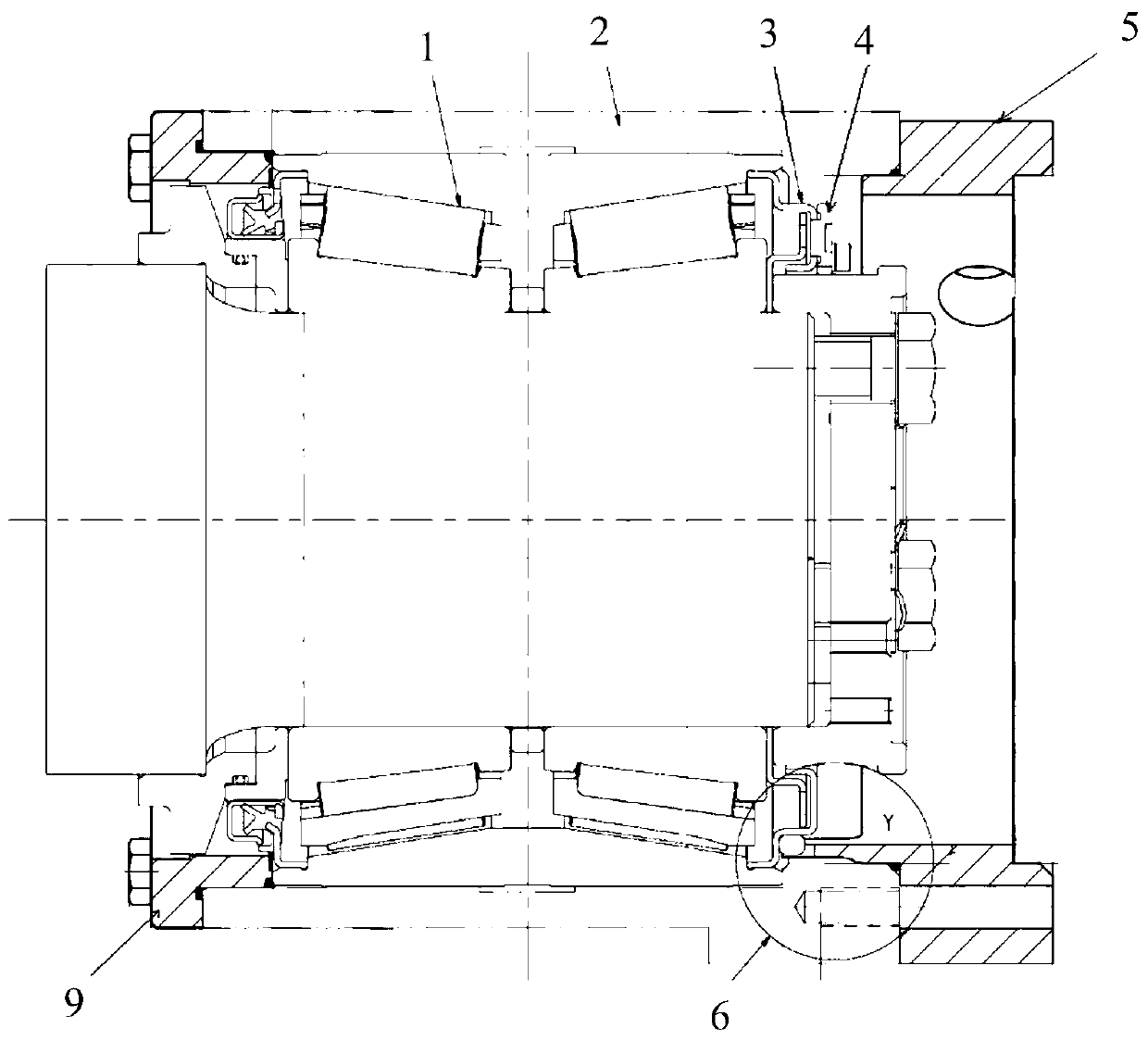

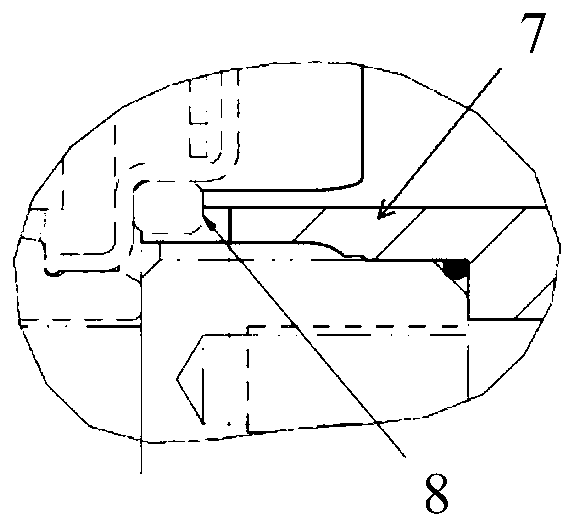

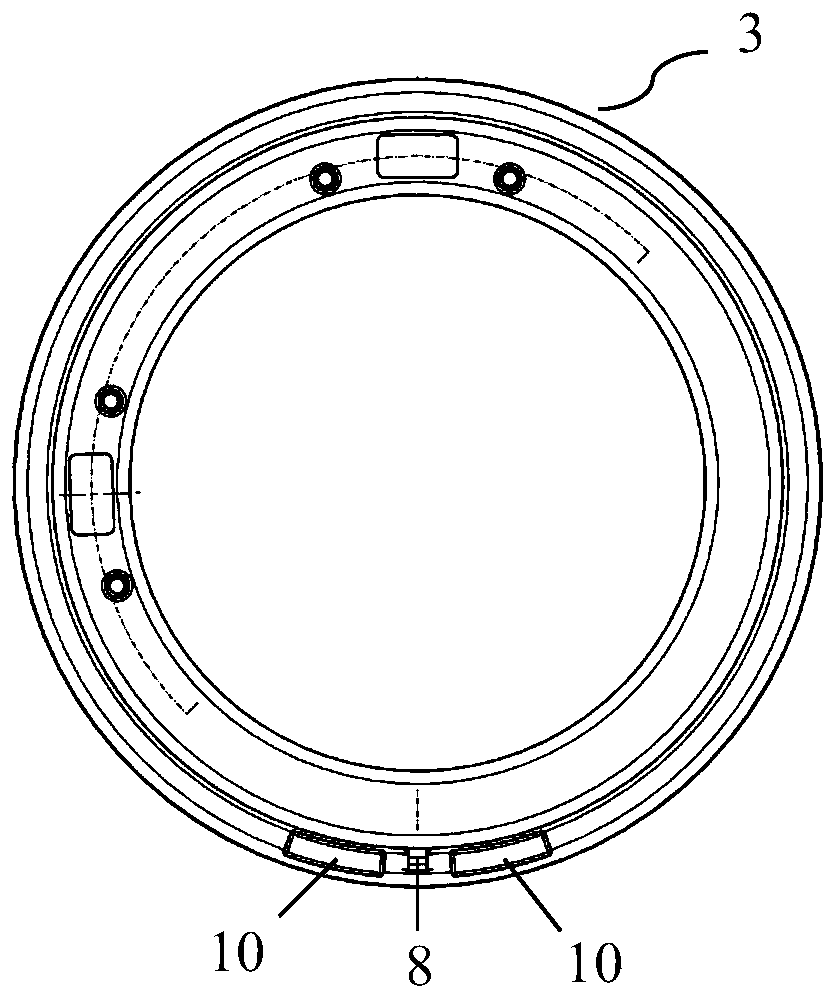

[0027] figure 1 A sectional view of an axle box arrangement according to a preferred embodiment is shown. The axlebox assembly includes an axlebox housing, a bearing unit and a sensor assembly.

[0028] like figure 1 As shown, the axle box housing is of split structure. The axlebox housing includes reference figure 1 The axle box front end cover (not shown), the axle box middle cover 5 , the axle box main body 2 and the axle box rear end cover 9 are arranged sequentially from right to left. The axle box front end cover (not shown), the axle box middle cover 5, the axle box main body 2 and the axle box rear end cover 9 are fixedly connected to each other to form a complete and stable axle box shell.

[0029] The bearing unit is accommodated in the axle box housing. The bearing unit includes a rolling bearing 1 and a sealing device. In this embodiment, the rolling bearing is designed as a double-row tapered roller bearing. Specifically, the rolling bearing 1 includes an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com