Method and device for measuring three-direction cutting force of fast tool servo turning

A measurement method and technology of cutting force, which is applied in the field of cutting force measurement and optical parts cutting processing, ultra-precision cutting, and can solve the problems that cutting force cannot be measured in three directions at the same time, and the measured value of cutting force contains driving force components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

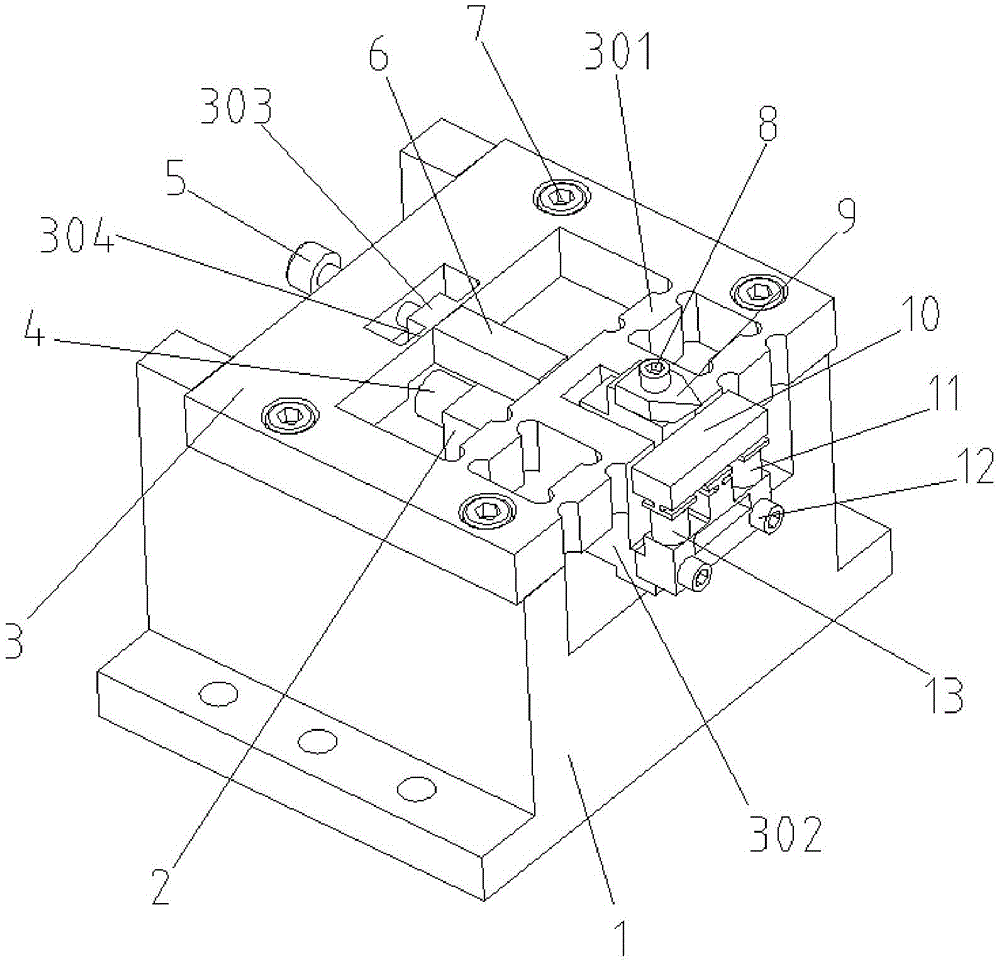

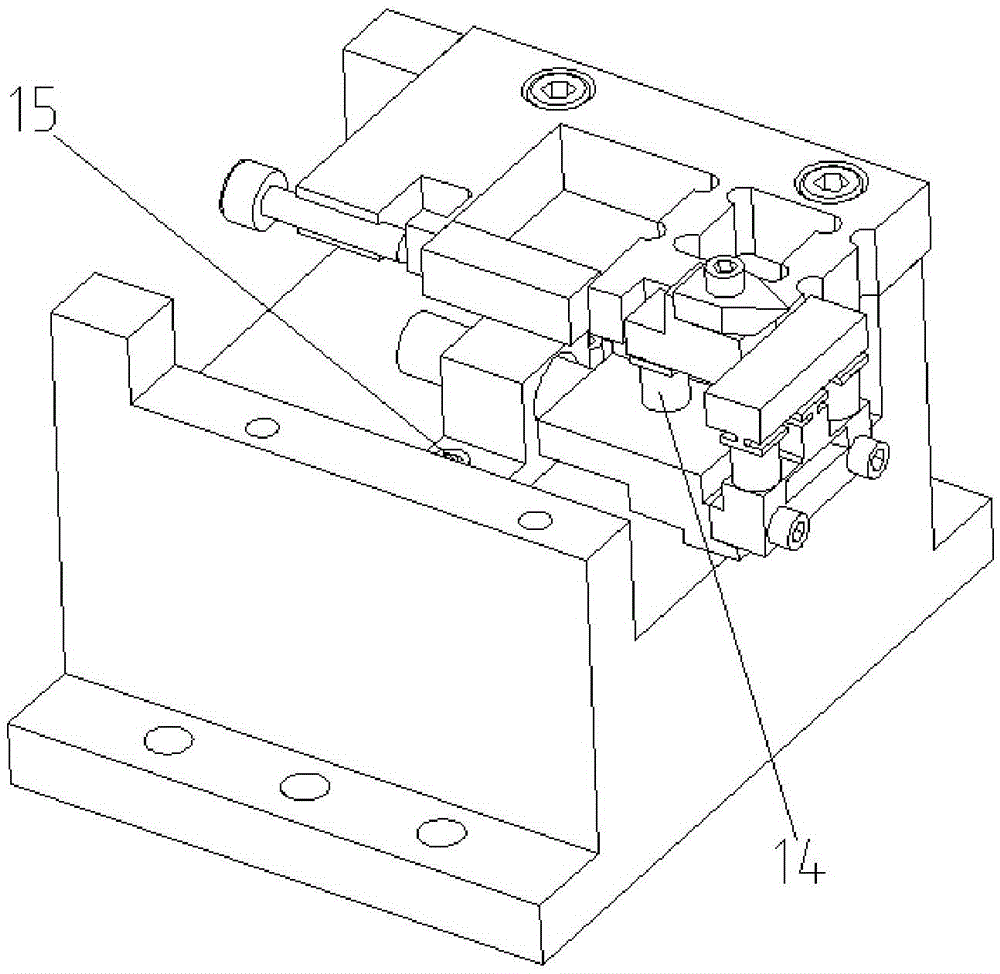

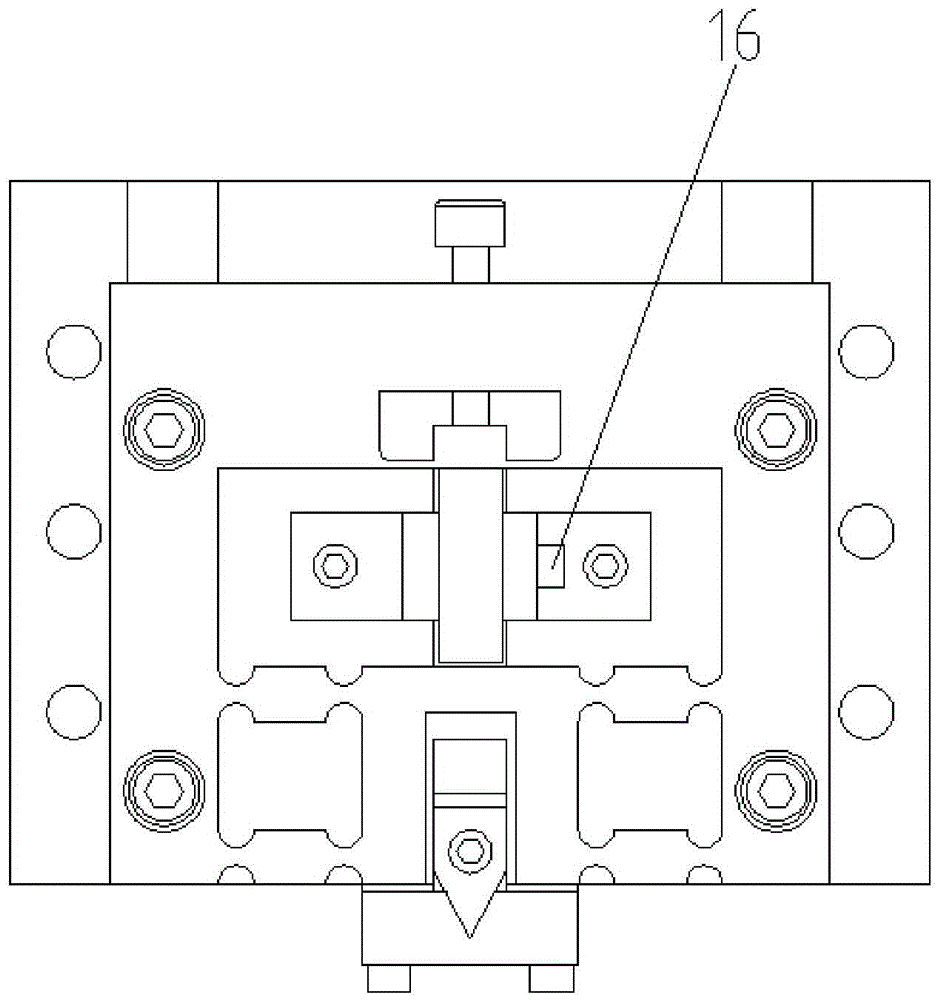

[0079] see Figure 1-19 shown.

[0080] A three-way cutting force measurement method for fast tool servo turning, the implementation steps are as follows:

[0081] (1) Pressure sensor one 11, pressure sensor two 13 and pressure sensor three 14 are installed on the micro-movement platform 302 of the fast tool servo mechanism along the Y direction, wherein pressure sensor one 11 and pressure sensor two 13 are installed on the front end, Pressure sensor 3 14 is installed inside the micro-motion platform 302, pressure sensor 1 11, pressure sensor 2 13 and pressure sensor 3 14 are distributed in an isosceles triangle, pressure sensor 1 11 and pressure sensor 2 13 are located at the base of the isosceles triangle On, the pressure sensor three 14 is located at the apex;

[0082] (2) Compress pressure sensor one 11, pressure sensor two 13 and pressure sensor three 14 with T shape lever type tool rest 10, diamond turning tool 9 is installed on T shape lever type tool rest 10, and wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com