Flannel fabric strip cutting machine

A flannel and slitting machine technology, which is applied in the direction of cutting velvet loops, can solve the problem of inability to ensure the accuracy of the cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

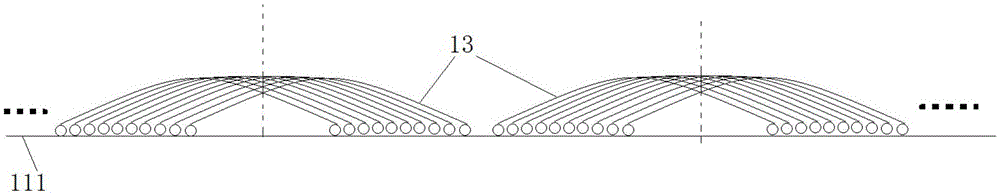

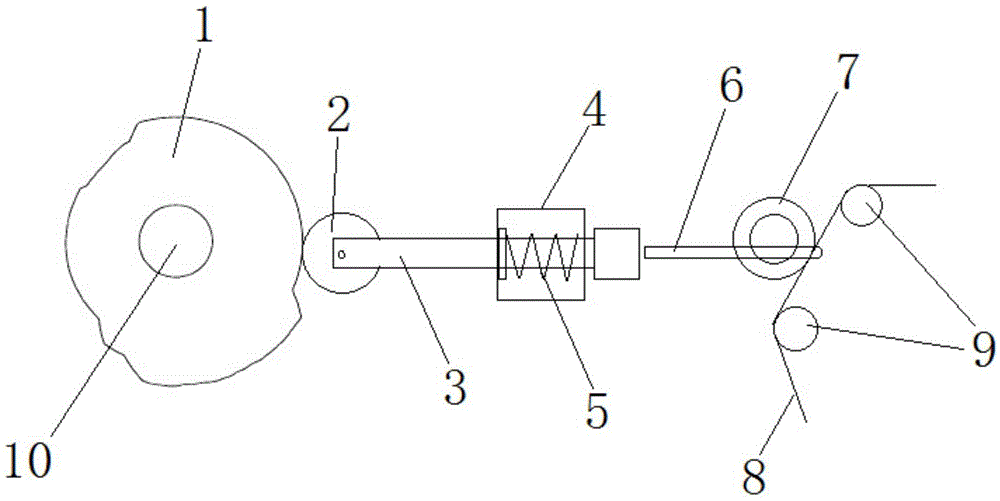

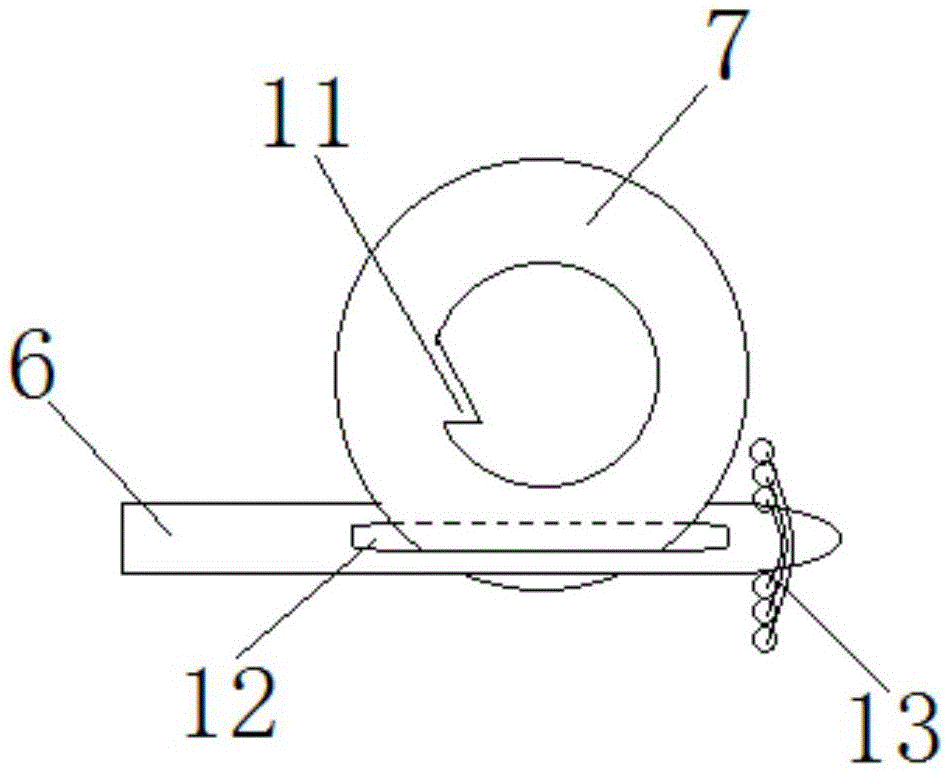

[0023] Such as figure 2 , 3 Shown, a kind of flannel fabric stripping machine comprises some cutting mechanisms and feeding mechanism, and feeding mechanism is delivered to the fabric of roll to several cutting mechanisms limit and carries out face thread 13 (as image 3 shown) cutting. The specific quantity of the cutting mechanism is determined according to the quantity of corduroy formed on the fabric surface.

[0024] The cutting mechanism includes a cam 1, and the cams 1 of several cutting mechanisms are installed on the same shaft 10 and driven by a power device. The side of the cam 1 is provided with a push rod 3, and the side where the push rod 3 is in contact with the cam 1 is provided with a roller 2. As the cam 1 rotates, the cam 1 pushes the push rod 3 to move, and between the push rod 3 and the cam 1 The roller 2 pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com