Bridge beam arch rib section manufacturing process

A manufacturing process and technology of bridges, applied in the direction of bridges, bridge construction, bridge forms, etc., can solve the problems that cannot meet the requirements of matching assembly production, difficult to control the line camber, inconvenient connection, etc., and achieve the construction quality is easy to guarantee, The effects of shortening the assembly cycle and facilitating transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The manufacturing process of the arch rib section of the bridge in this embodiment is as follows:

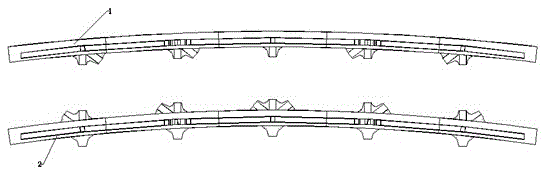

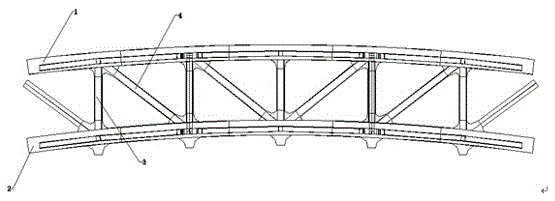

[0024] (1) Assembly of trusses: The overall trusses of the main truss of the arch rib are composed of upper chord 1, lower chord 2, straight web 3, and oblique web 4, and a single internode is a truss;

[0025] The overall truss is assembled by multi-segment continuous matching, that is, each round is assembled with no less than 5 segments, and the open-air assembly is carried out under the condition of no sunshine; when assembling, if figure 1 As shown, firstly, the upper chord 1 and the lower chord 2 are positioned in parallel on the tire frame A, and the tire frame A is set according to the arch rib of the bridge, and the chord positioning piers and the oblique pole positioning piers are also arranged on the tire frame A, and the Set up temporary buttresses and limit gear angles; through adjustment, reserve 3mm welding shrinkage between upper chord 1 and lower chord 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com