Dust-unloading vacuum dust control device of sweeper truck

A road sweeper and vacuum technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of complex internal structure of road sweeper, difficult cleaning of dust settlement, and low dust removal efficiency, so as to improve the working dust discharge environment and avoid The effect of secondary dust raising and increasing the dust collection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

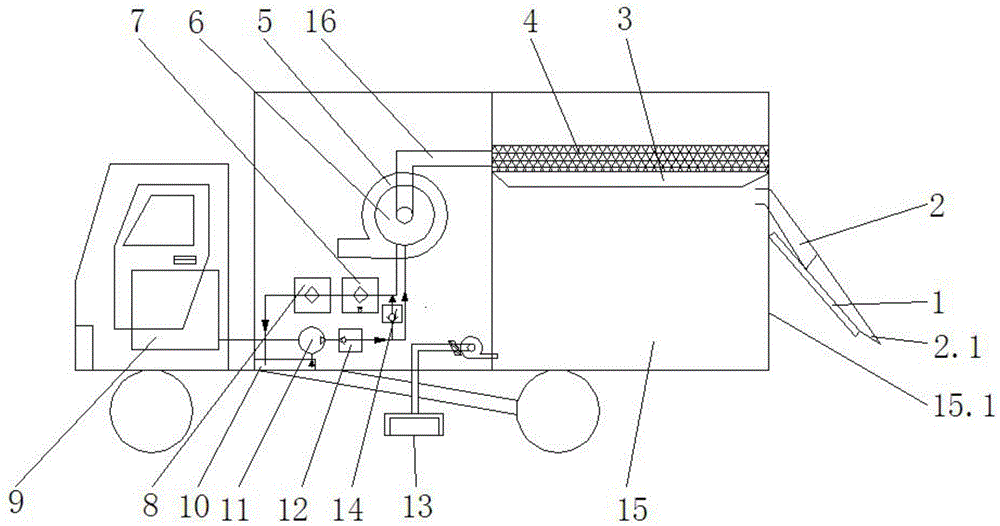

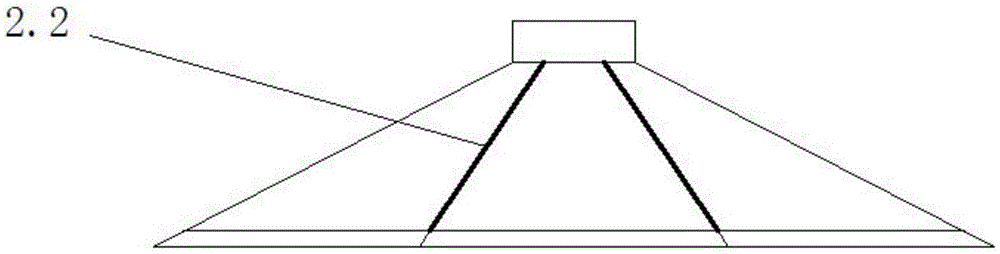

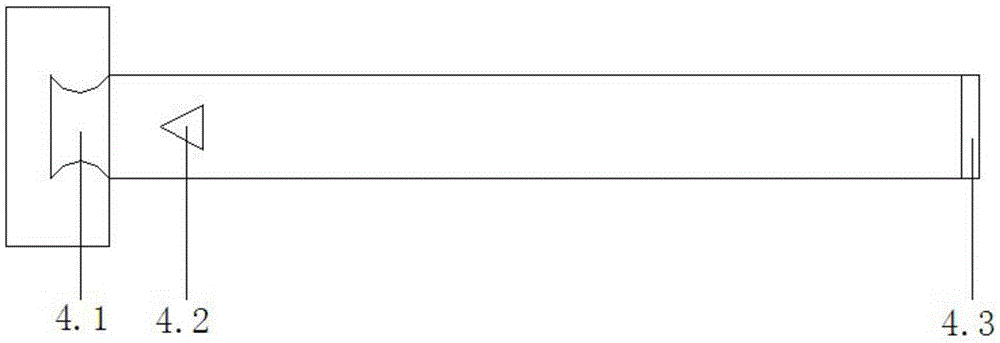

[0022] Such as figure 1 The shown ash unloading vacuum dust control device for a road sweeper includes a hydraulic power system, a fan 5 and a driving dust suction port 13 facing the ground; the device also includes a dust storage box 15, and the driving dust suction port 13 passes through the pipeline It communicates with the lower part of the dust box 15, and the upper part of the dust box 15 communicates with the air outlet duct 16, and the fan 5 driven by the hydraulic power system is installed in the air outlet duct 16; the tail box 15.1 of the dust box 15 is provided with Rear box cover 1, on the afterbody box body 15.1 above rear box cover 1, stretch out dust-discharging and dust-absorbing pipeline 2, the outlet of unloading dust-absorbing pipeline 2 communicates with dust box 15 in re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap