Revision method and apparatus of work parameters of fuse

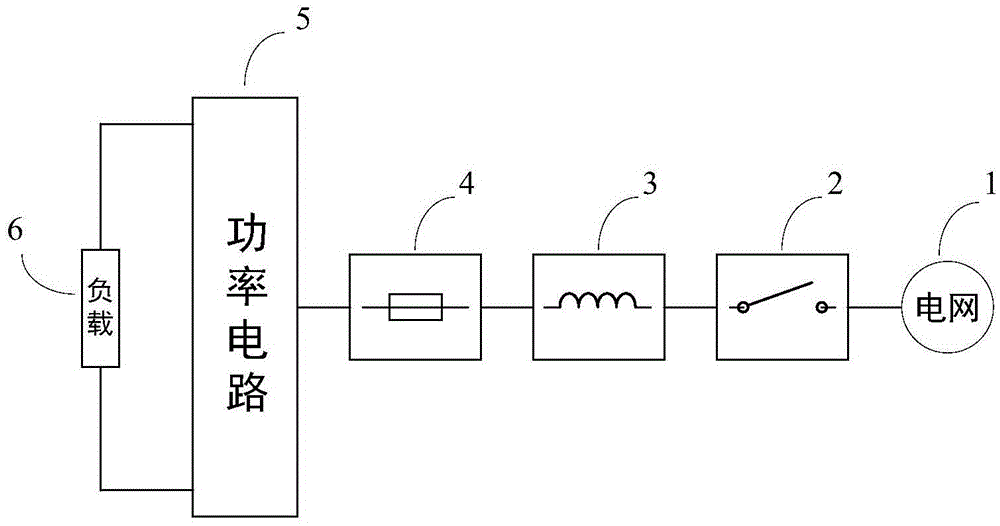

A technology of working parameters and fuses, applied in parameter calibration/setting, emergency protection circuit devices, electrical components, etc., can solve problems such as inability to select fuses, excessive protection margin of fuses, etc., and achieve increased selection The effect of range, accurate selection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

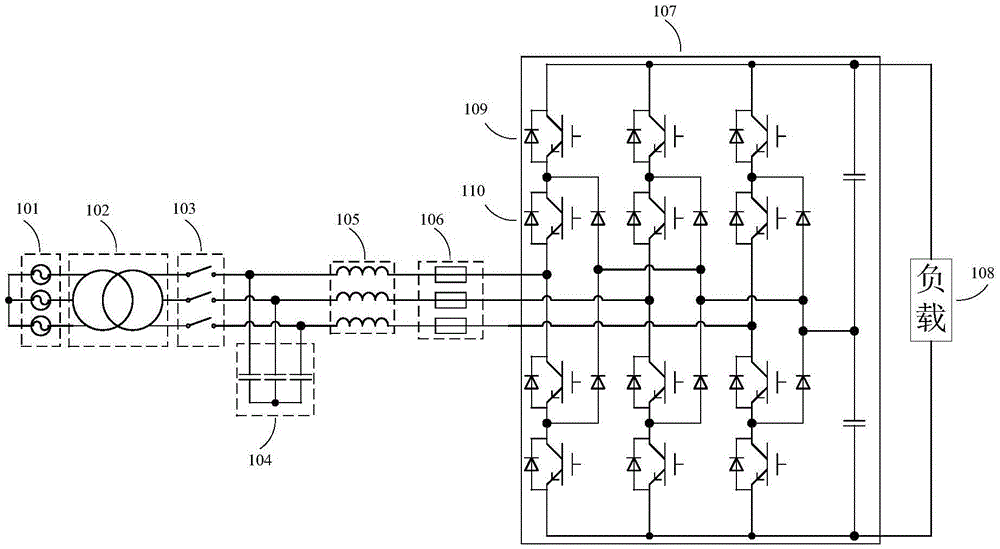

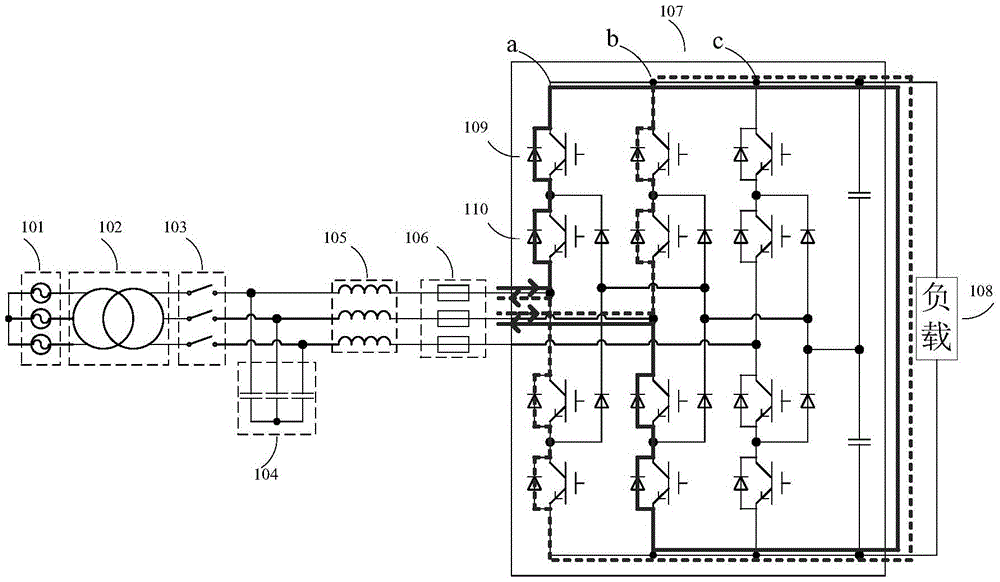

[0032] In wind power converters, fuses are used to protect higher value diodes, and their design selection plays an important role in converter design. The revision method of the working parameters of the fuse of the present invention "refines" the selection process of the fuse, fully considers the actual operating parameters such as temperature, and optimizes the fuse by analyzing and calculating the characteristics of the diode and the fuse at different currents and temperatures. It improves the design method of fuses, realizes more accurate fuse selection, and avoids the disadvantages of large errors in traditional selection only based on data sheets.

[0033] Figure 8 It is a schematic flowchart of an embodiment of the method for revising the operating parameters of the fuse in the present invention. Such as Figure 8 As shown, the revision method of the fuse working parameters in this embodiment may specifically include:

[0034] S201: The step of obtaining the short-...

Embodiment 2

[0042] Figure 9 It is a structural schematic diagram of an embodiment of the device for revising the working parameters of the fuse of the present invention. Such as Figure 9 As shown, the device for revising the working parameters of the fuse in this embodiment can be implemented as Figure 8 A method for revising operating parameters of a fuse in the illustrated embodiment.

[0043] Specifically, the device for modifying the working parameters of the fuse in this embodiment may include: a short-circuit current value obtaining module 301 for obtaining different short-circuit current values under different voltage cut-in angles; a diode damage time-short-circuit current curve obtaining module 302 for obtaining To obtain the damage time-short-circuit current curve of the diode at different temperatures; the fuse time-short-circuit current curve obtaining module 303 is used to obtain the fuse-time-short-circuit current curve of the fuse; the experiment module 304 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com