Quartz material screening system and screening method

A quartz material and flotation technology, applied in separation methods, chemical instruments and methods, mixed material pretreatment, etc., can solve problems such as unfavorable promotion and use, screening process, complex conditions, etc., to facilitate later promotion and use, and improve mineral processing Effect, screening process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

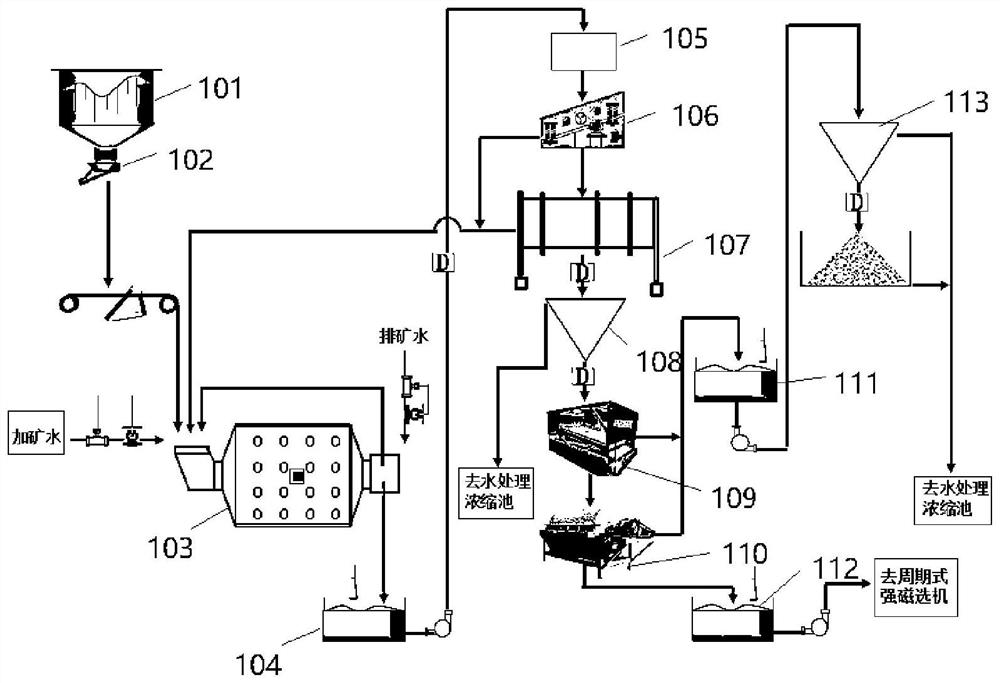

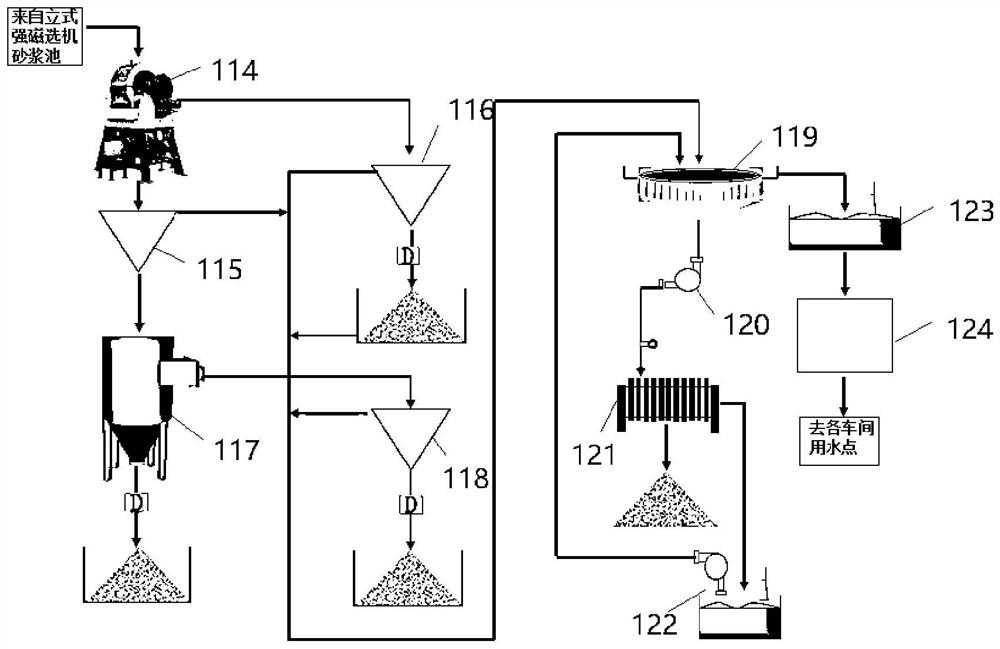

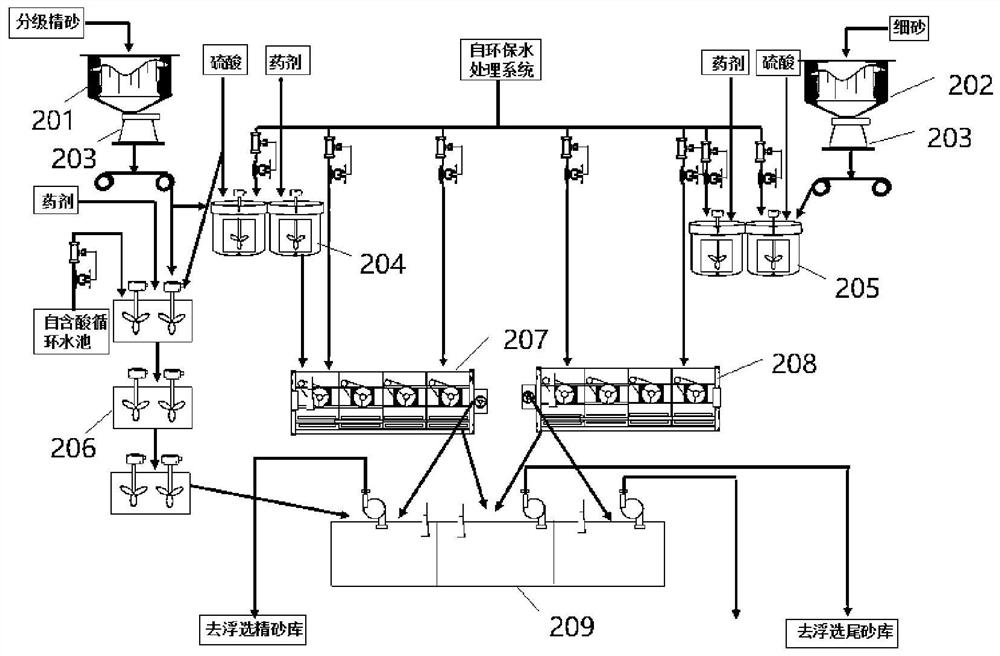

[0037] Such as figure 1 As shown, the present invention provides a screening system for quartz materials, including a beneficiation unit, a flotation scrubbing unit, and a medicament preparation unit. It should be noted here that, if Figure 5 As shown, the first row of the medicine preparation unit is a sulfuric acid preparation system, the second and third rows are medicine preparation devices, and the preparation process and preparation device of the third row are the same as those of the second row, which will not be described in detail here.

[0038] The beneficiation unit includes a silo 101, a vibrating feeder 102, a rod mill 103, a vibrating screen 106, a drum screen 107, a first mortar storage bucket 108, a plate magnetic separator 109, a vertical magnetic separator 110, and a periodic magnetic separator. Selection machine 114, hydraulic classifier 117. The top of the feed bin 101 is cylindrical, and the bottom is conical, which is convenient for the lowering of min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com