Permanent magnet rotating speed difference clutch and self-adaption nonsingular terminal slip form rotating speed control method thereof

A non-singular terminal and clutch technology is applied in the field of permanent magnet slip clutch adaptive non-singular terminal sliding mode speed control, which can solve problems such as external interference and parameter perturbation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0051] A permanent magnet slip clutch adaptive non-singular terminal sliding mode speed control method, the specific steps are as follows:

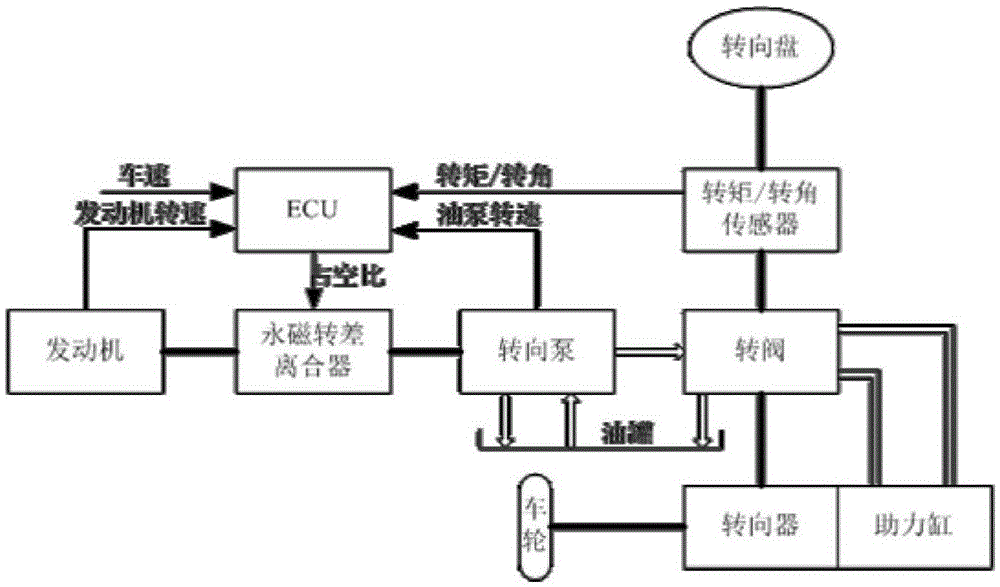

[0052] Step 1: Build a permanent magnet slip clutch type electronically controlled hydraulic power steering system

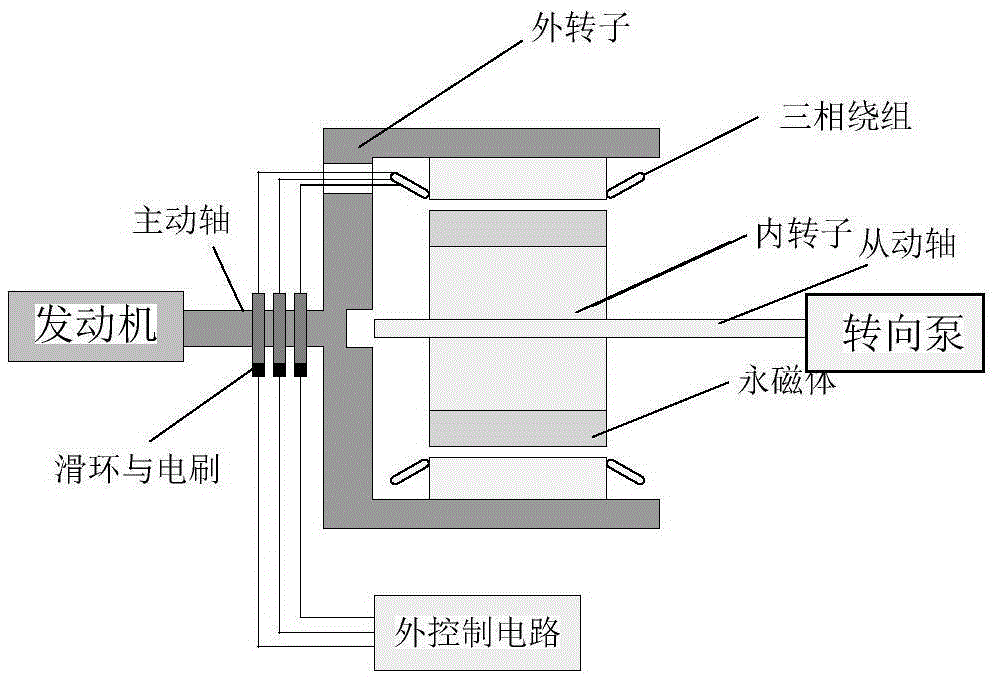

[0053] Such as figure 1 , As shown in 2, the permanent magnet slip clutch is mainly composed of an outer rotor, an inner rotor and an outer control circuit. The outer rotor is embedded with three-phase windings, which are connected to the external control circuit through slip rings and brushes, and the inner rotor is surface-attached with permanent magnets to form a hidden pole inner rotor structure. The outer rotor is the input end, which is connected to the engine through the driving shaft, and the inner rotor is the output end, which is connected to the steering pump through the driven shaft, thus for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com