Hybrid power steering system parameter matching method

A technology of steering system and hybrid power, which is applied in the direction of power steering mechanism, electric steering mechanism, steering mechanism, etc. It can solve the problem that the hydraulic power steering system cannot perform active angle and torque control, and the electric power assist motor cannot output the maximum electromagnetic torque. Limiting the maximum electromagnetic torque output of the booster motor, etc., to achieve the effect of ensuring the portability of steering, improving fuel economy and reducing waste loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

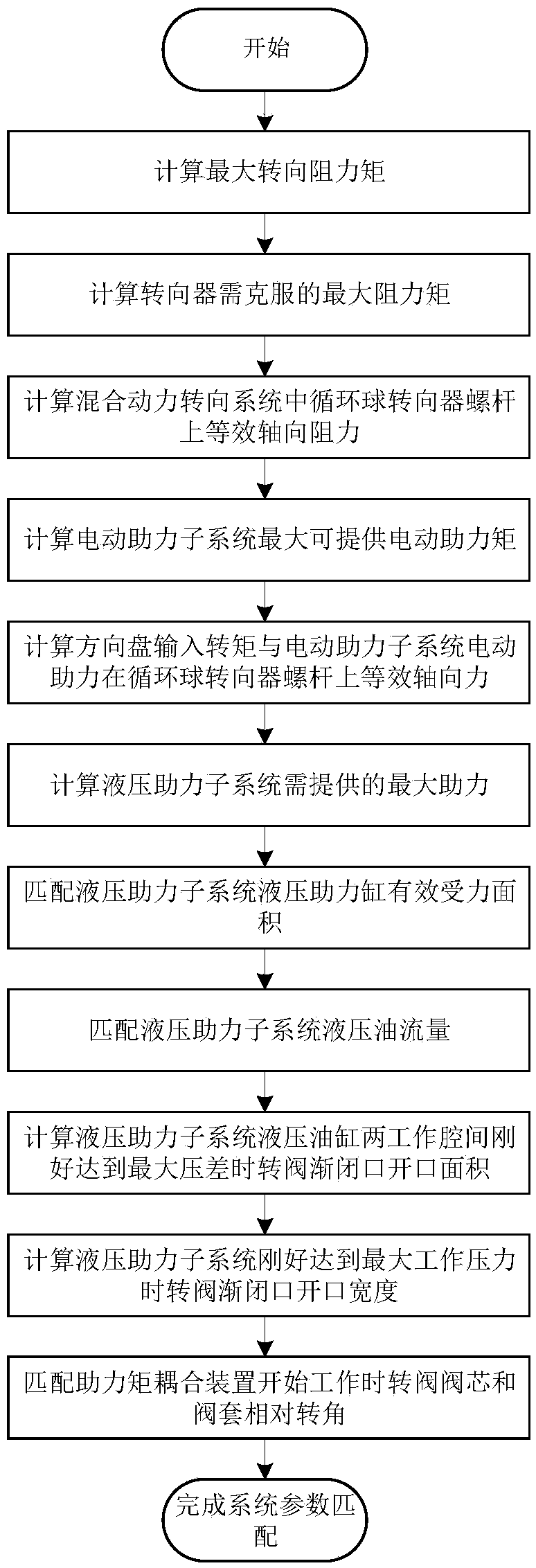

[0051] In the specific implementation, a commercial vehicle with a front axle load of 5.6 tons is taken as an example for system parameter matching, and a system parameter matching method for a hybrid power steering system is described.

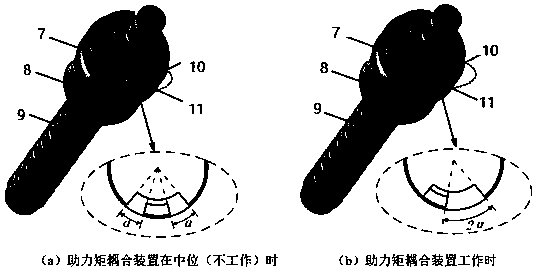

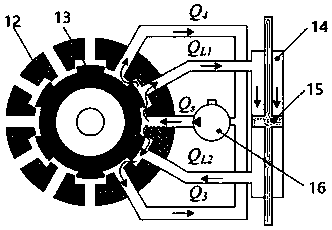

[0052] The structure of the hybrid power steering system is shown as figure 2 As shown, it includes electric power assist subsystem, hydraulic power assist subsystem and recirculating ball mechanical subsystem. The hydraulic booster subsystem mainly includes hydraulic booster cylinders, rotary valves, torsion bars, hydraulic pipelines, hydraulic pumps, and booster torque coupling devices. The electric power assist subsystem mainly includes a power assist motor, a torque angle sensor and a reduction mechanism. The recirculating ball mechanical subsystem mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com