Spirally-through spraying cleaning machine

A technology for spray cleaning and cleaning cavity, applied in the field of cleaning machines, can solve the problems of large waste of cleaning liquid, inability to realize continuous cleaning process, low efficiency, etc., and achieve the effect of saving the use of cleaning liquid, reliable cleaning effect, and reliable cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

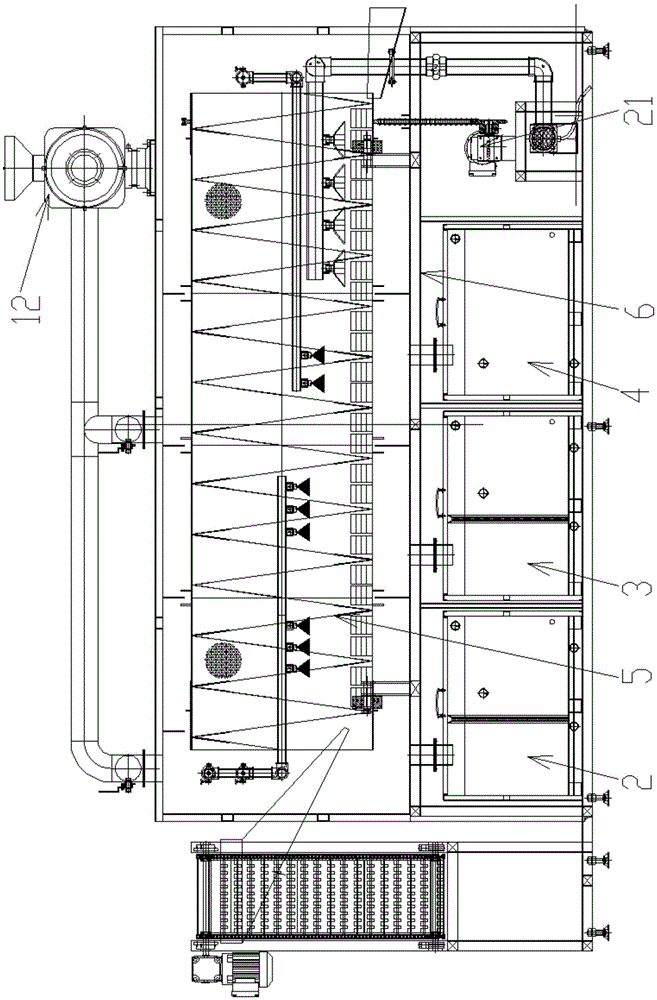

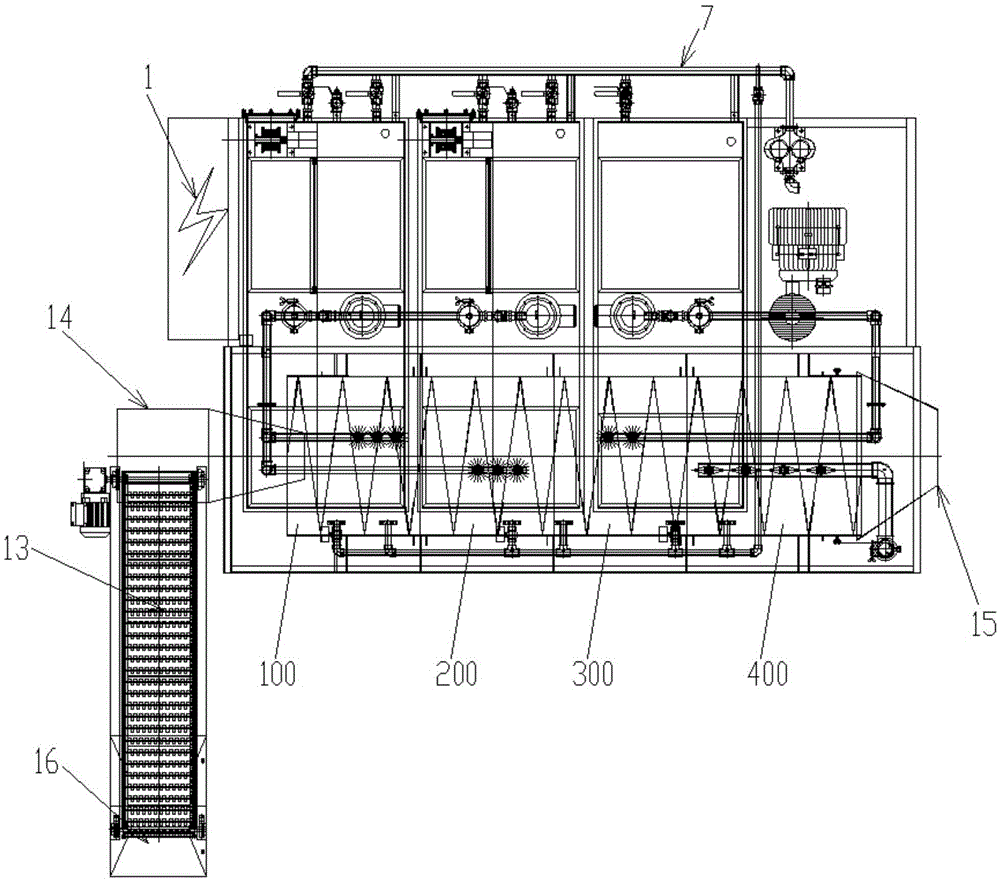

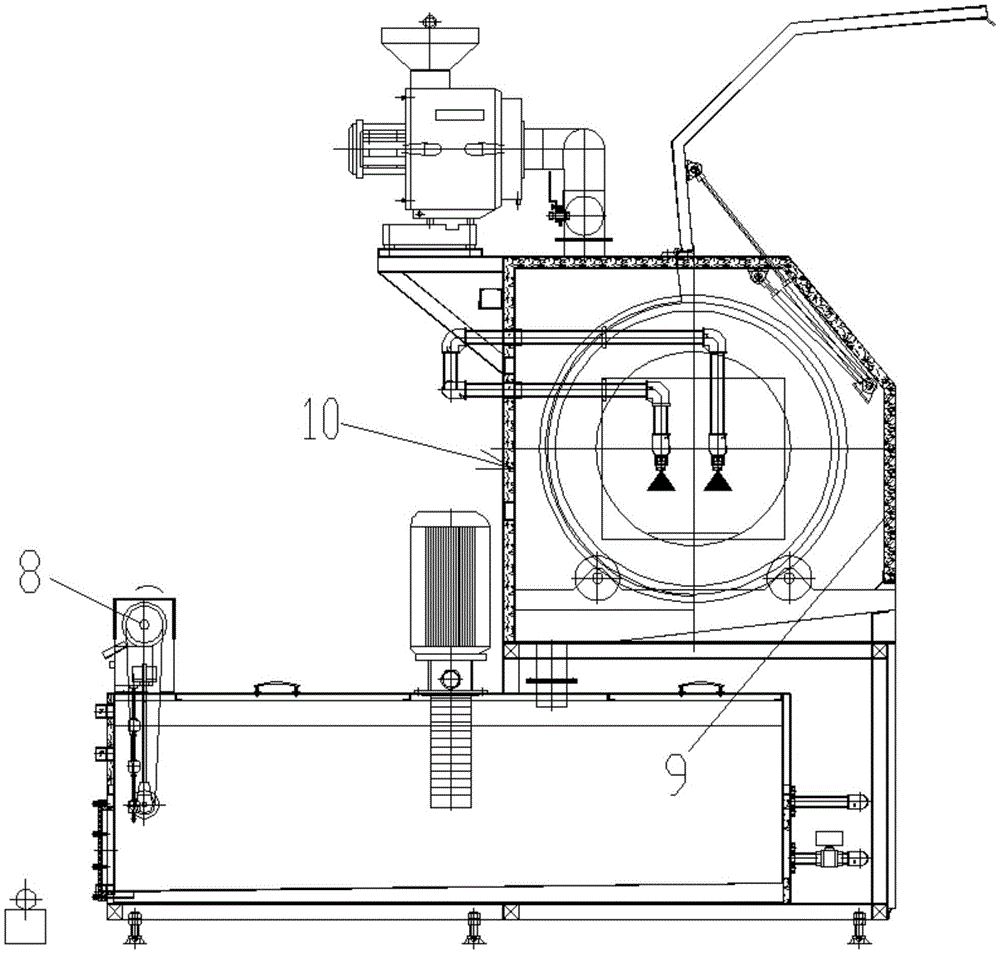

[0031] Such as Figure 1~3 Shown, it has shown the specific embodiment of the present invention, thread through type spray cleaning machine, comprises frame; Tank body 10 is fixedly arranged on the frame; Rotating cage conveying mechanism 5 is installed in the tank body; In the rotating cage conveying mechanism The first spray assembly 100, the second spray assembly 200, the passivation cleaning assembly 300 and the hot air drying assembly 400 are arranged in sequence;

[0032] As shown in the figure, the tumbler conveying mechanism includes a tumbler; the tumbler as a whole is a cylindrical structure placed horizontally, and through holes are evenly distributed on the wall of the tumbler; a spiral groove is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com