3M glue auto-pasting and die-cutting machine

An automatic patch and die-cutting machine technology, applied in lamination devices, metal processing, lamination, etc., can solve the problems of low processing efficiency and manual operation, and achieve the effect of convenient operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

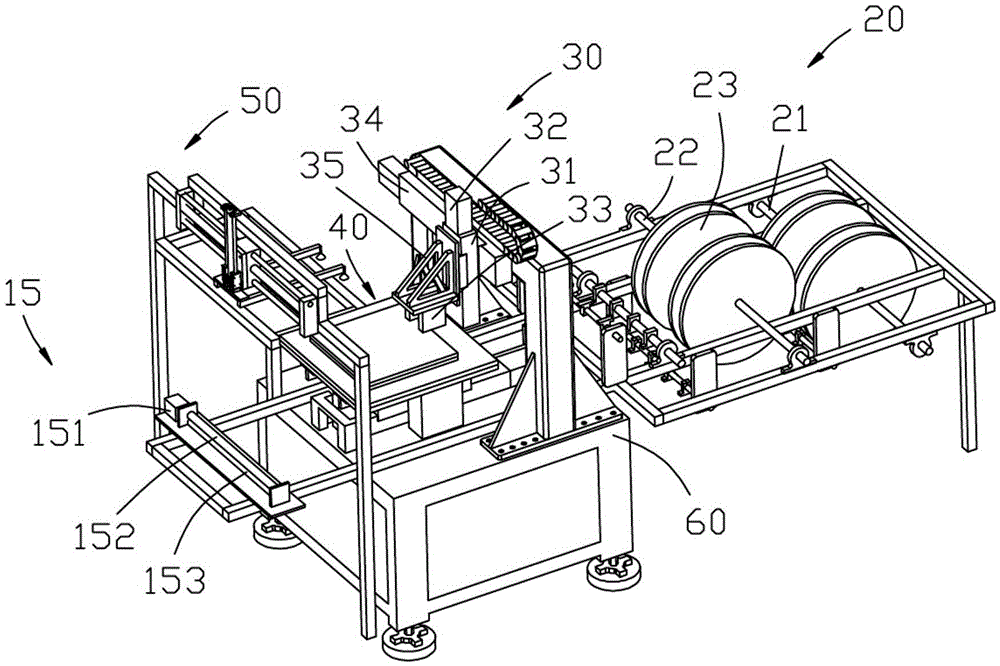

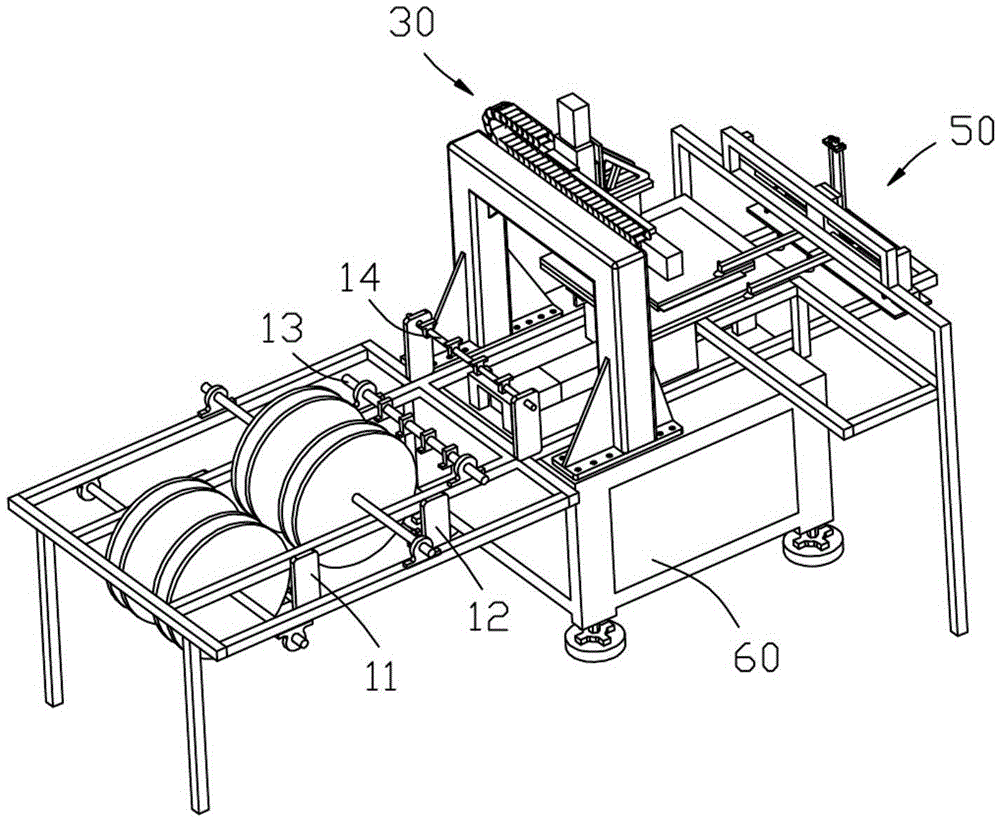

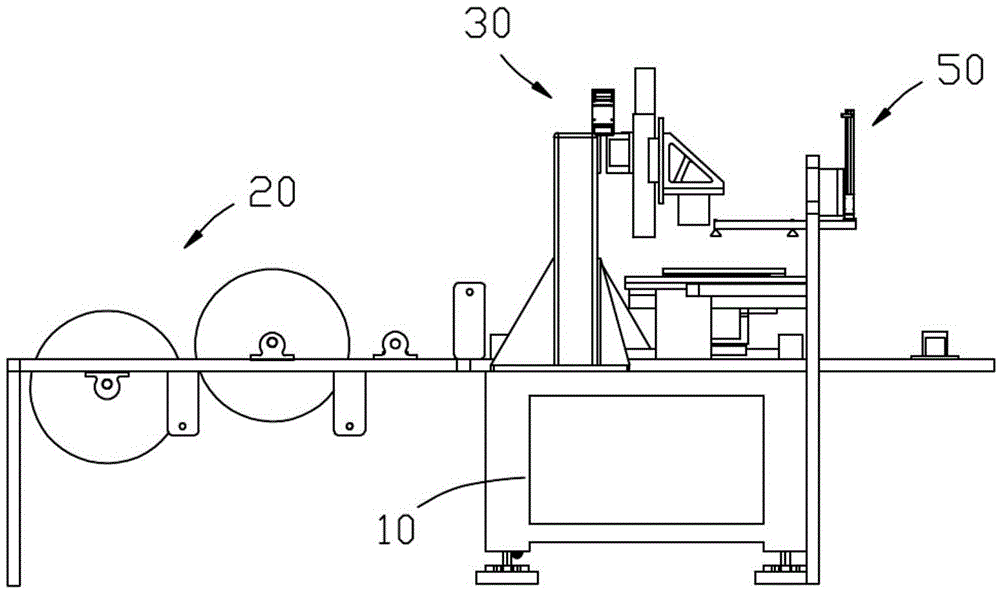

[0018] like Figure 1 to Figure 6 Shown, a kind of 3M self-adhesive automatic patch die-cutting machine comprises frame 60, and described frame 60 is provided with feeding assembly 10, film assembly 20, shearing tool assembly 30, shearing platform assembly 40 and handling Component 50; the feeding component 10 includes four drive rollers and a speed regulating component 15, and the side of the feeding component 10 is provided with a film sticking component 20, and the film sticking component 20 includes a first film sticking roller 21 and a second film sticking roller 22 , four laminating rollers 23 are respectively installed on the first laminating roller 21 and the second laminating roller 22; the downstream of the feeding assembly 10 is provided with a shearing cutter assembly 30, and the shearing cutter assembly 30 includes a shearing cutter motor 31 and a cutter 33, The below of described cutter 33 is provided with shearing platform assembly 40, and the side of shearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com