Side wall structure of railway vehicle

A technology for the side wall and side wall structure of rail vehicles, which is applied in the field of airtight wall panels, can solve the problems of inability to meet the requirements of faster vehicles, the installation structure, the overall rigidity and strength are not perfect, etc., to improve the appearance effect and improve the aesthetics. , the effect of reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The rail vehicle side wall structure described in the present invention is mainly applied to the rail vehicle body.

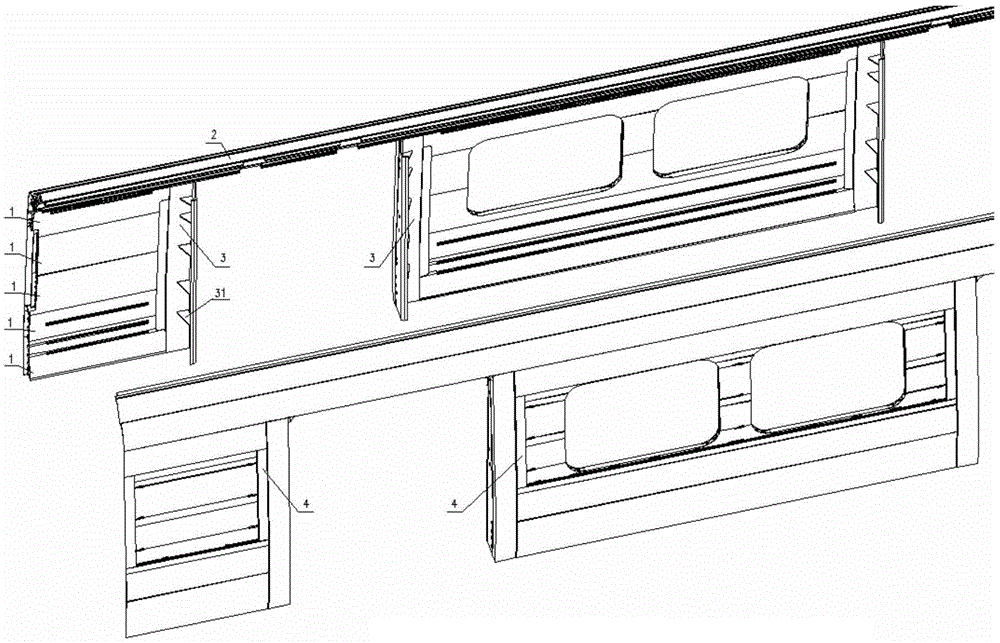

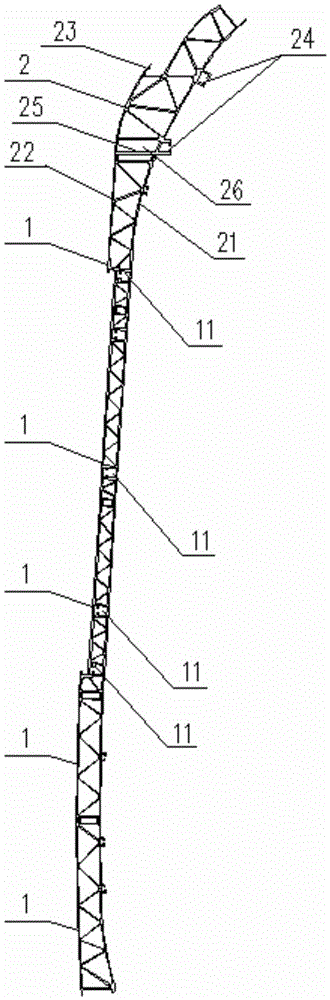

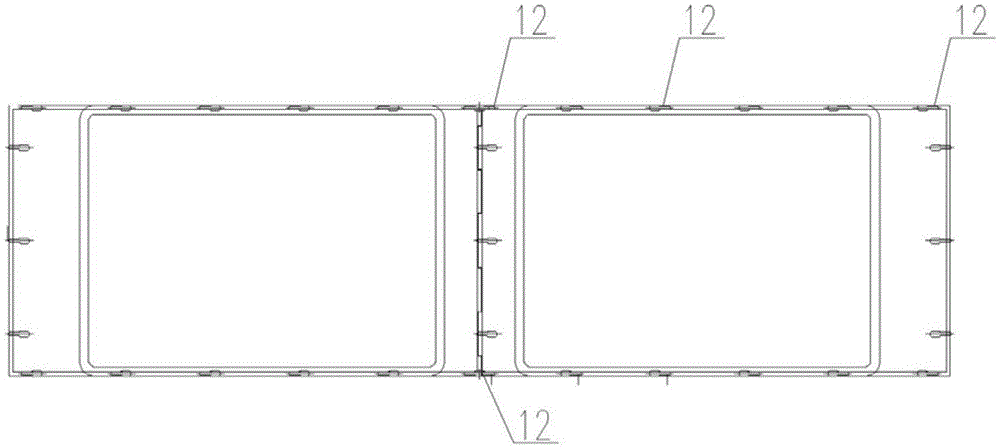

[0027] Such as figure 1 As shown, the rail vehicle side wall structure mainly includes a plurality of side wall profiles 1 , upper side beam profiles 2 , door columns 3 , and window columns 4 . The side wall profile 1 and the upper side beam profile 2 are hollow aluminum alloy extruded profiles, and continuous welding is adopted between each profile in the length direction of the car body. Continuous welding is adopted on the outer side of the room, and segmental welding is adopted on the side wall structure and the inner side of the side beam of the underframe.

[0028] The side wall structure and the underframe, roof, end wall and other large components are welded to form a complete thin-walled cylindrical overall load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com