Safe fastening structure for logistics goods box and operating method thereof

A technology for fastening structures and cargo boxes, applied in the direction of locking equipment, etc., can solve problems such as waste of manpower, pad slipping, low efficiency, etc., and achieve the effects of improving efficiency, saving costs, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

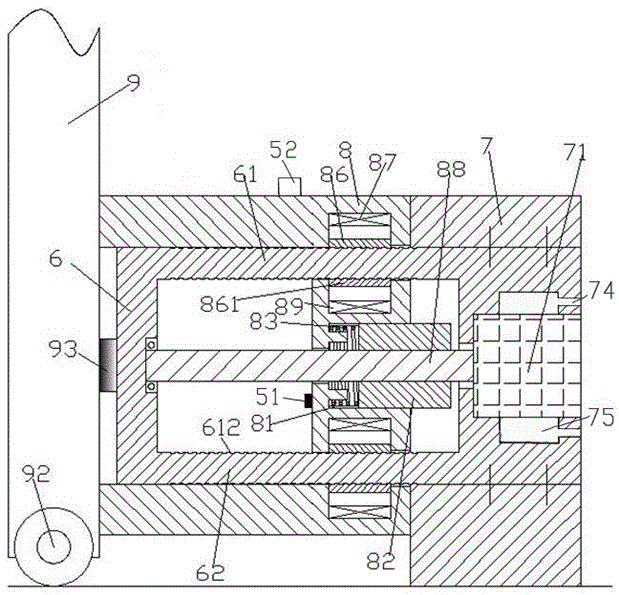

[0010] Combine below Figure 1-2 The present invention will be described in detail.

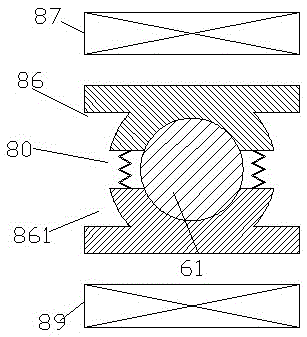

[0011] A secure fastening structure for logistics cargo boxes according to an embodiment, including a side wall fixing part 7, a position locking part 6 fixedly connected with the side wall fixing part 7, a movable force transmission part 8 and a pressing execution part 9 ; Wherein, the movable force transmission part 8 is extended to be fixedly connected with the compression execution part 9; Two guide belt tooth columns 61, 62, each of the guide belt tooth columns 61, 62 is provided with a plurality of circumferentially extending protruding rings 612 evenly distributed, and the movable force transmission part 8 includes a The circumferentially extending protruding rings 612 of the two guide belt toothed columns 61, 62 are matched and symmetrically arranged clamping shoe assemblies, each of which includes two toothed clamping shoes 86, 861 oppositely arranged , the two toothed clamping sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com