Large-size black phosphorus slice and preparation method thereof

A technology of large-size black phosphorus flakes, which is applied in the field of large-size black phosphorus flakes and its preparation, can solve the problems of low yield of flake black phosphorus, few black phosphorus flakes, and difficulty in repeating, and achieves low price, simple operation, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of large-size black phosphorus sheet, comprising the steps of:

[0047] Add 15mL of dimethyl sulfoxide solution to a 30mL beaker, then add 5mg of black phosphorus, the magnetic stirring speed is 3000 rpm, after stirring for 20h, the resulting mixed solution is centrifuged at 3000rpm for 10min, and the supernatant is taken Then centrifuge at 13000rpm for 10min, and wash the obtained precipitate several times with absolute ethanol to obtain large-sized black phosphorus tablets.

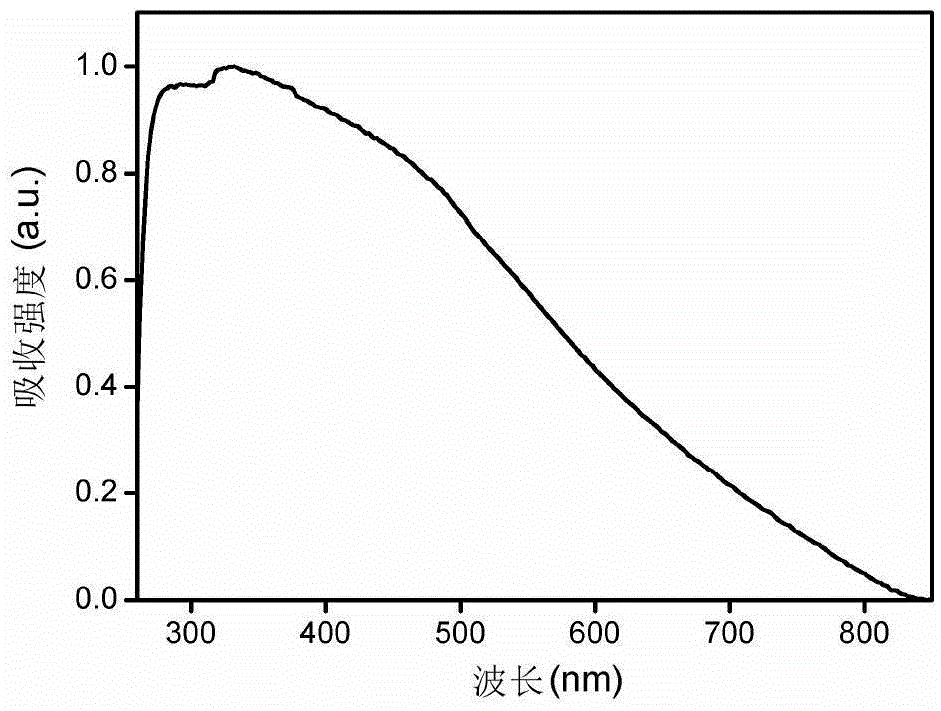

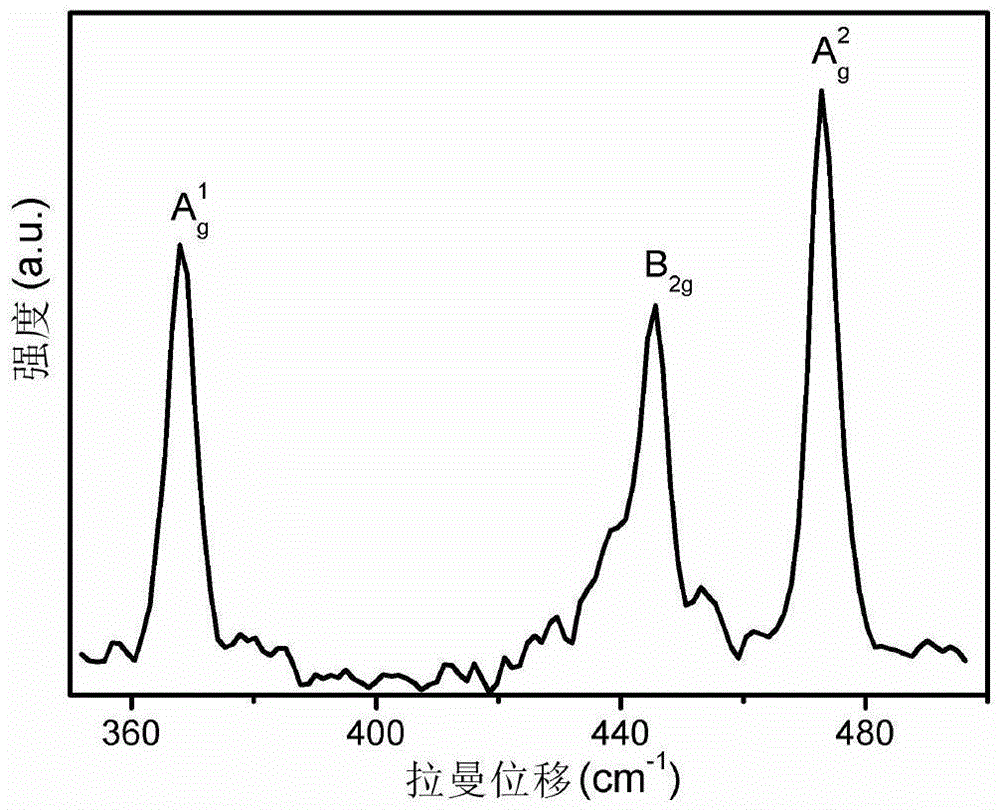

[0048] The product obtained in present embodiment 1 is characterized, and the results are as follows Figure 1 to Figure 4 As shown, among them, figure 1 is the UV-Vis-NIR absorption spectrum of the product, from figure 1 It can be seen from the curve in that the product of Example 1 has absorption in the range of 300-800nm, and its absorption peak is about 330nm; figure 2 For its Raman spectrum, from figure 2 It can be seen from the curve in , at 368cm -1 、446cm -1 a...

Embodiment 2

[0050] A preparation method of large-size black phosphorus sheet, comprising the steps of:

[0051] Add 30mL dimethyl sulfoxide solution to a 50mL beaker, then add 5mg of black phosphorus, the magnetic stirring speed is 3000 rpm, after stirring for 25h, the resulting mixed solution is centrifuged at 3000rpm for 10min, and the supernatant is taken again Centrifuge at 13,000 rpm for 10 min, and wash the resulting precipitate with absolute ethanol several times to obtain large-sized black phosphorus tablets.

Embodiment 3

[0053] A preparation method of large-size black phosphorus sheet, comprising the steps of:

[0054] Add 15mL of dimethyl sulfoxide solution to a 30mL beaker, then add 5mg of black phosphorus, the magnetic stirring speed is 3000 rpm, after stirring for 30h, centrifuge the resulting mixed solution at a speed of 3000rpm for 10min, and take the supernatant Then centrifuge at 13000rpm for 10min, and wash the obtained precipitate several times with anhydrous ethanol to obtain large-sized black phosphorus tablets.

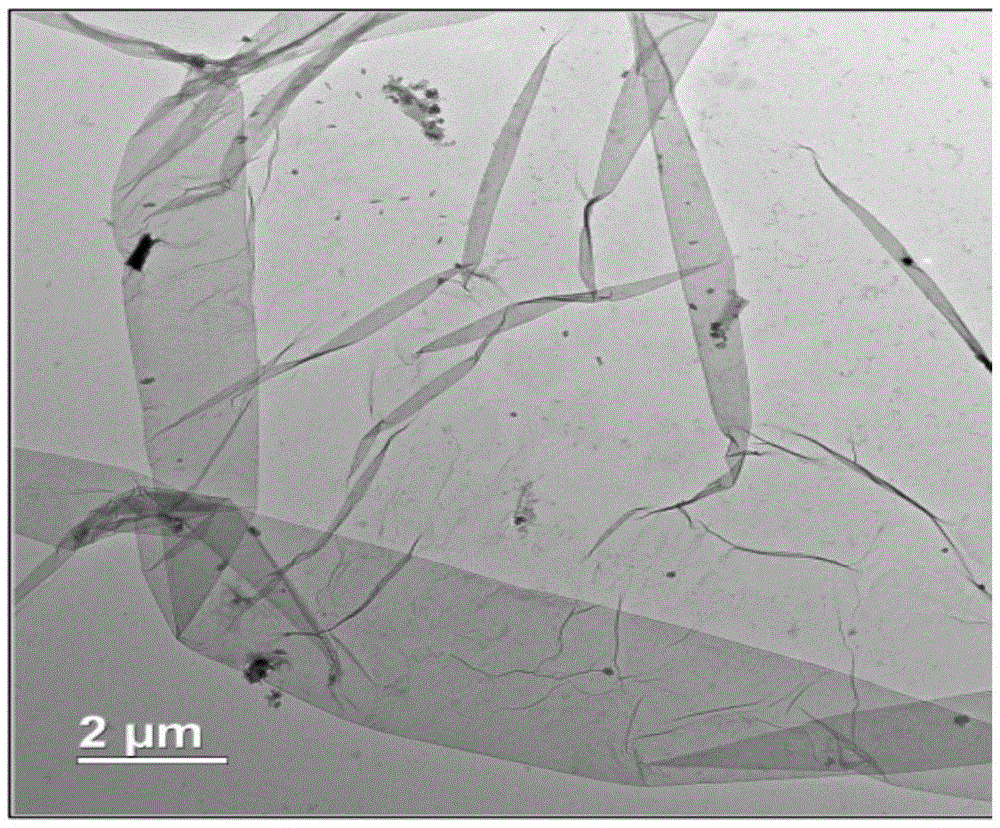

[0055] Figure 5 It is a transmission electron microscope image of the black phosphorus sheet prepared in Example 3 of the present invention. Depend on Figure 5 The resulting product is clearly seen as black phosphorus flakes with lateral dimensions of about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com