Biological composite material loading nano-silver particle

A technology of nano-silver particles and composite materials, which is applied in the field of bio-composite materials carrying nano-silver particles, can solve the problems of environmental hazards and high carrier cost, achieve the effects of low cost, short preparation period, and improve the current situation of fouling and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

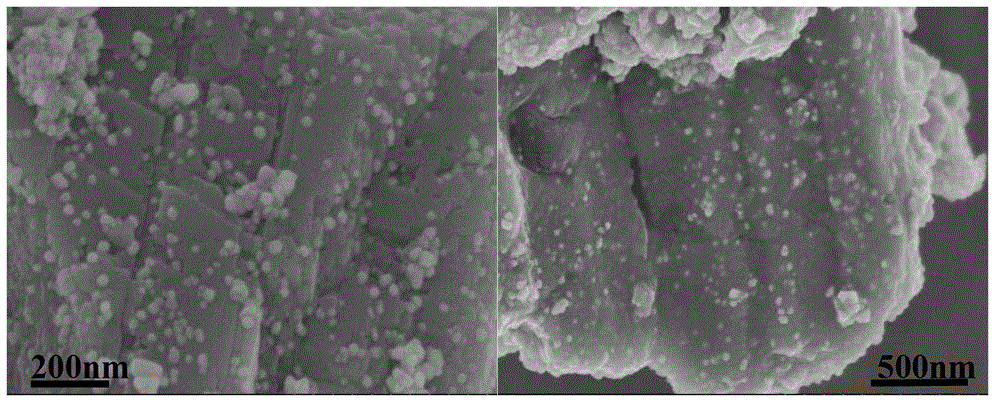

[0023] Take 50 mg of mussel shell powder (about 150 μm) and dissolve it in 100 ml of deionized water, stir at room temperature for 30 min after ultrasonication briefly, and then use a pipette gun to take 2 μL of silver nitrate solution with a concentration of 10 mM / L and slowly drop it into the above In the suspension, stir magnetically for 30 minutes to fully disperse on the powdered mussel shell matrix, then slowly drop 3 μL of glucose solution with a concentration of 0.22g / L into the above mixed solution, heat to 40°C and stir magnetically, and react The time is 1 h. During the whole reaction process, the auxiliary ultraviolet light is irradiated for 30 min, until the reaction solution turns from milky white to gray black, that is, the heating is stopped to end the reaction, the product is centrifuged, and the sediment is collected, and vacuum drying is completed at a temperature lower than 45 °C. preparation. Electron microscopy results such as figure 1 Shown: A large num...

Embodiment 2

[0025] Dissolve 100 mg of oyster shell powder (70-150 μm) in 100 ml of deionized water, briefly sonicate and stir at room temperature for 30 min, then use a pipette gun to take 5 μL of silver nitrate solution with a concentration of 10 mM / L and slowly drop it into the suspension In the solution, magnetically stirred for 30 min to fully disperse on the mussel shell powder matrix, and then slowly dripped 7.5 μL of glucose solution into the above mixed solution, heated to 60 °C and magnetically stirred, the reaction time was 1.5 h, the whole reaction process The auxiliary ultraviolet light was irradiated for 1 h until the reaction solution changed from milky white to gray black, that is, the heating was stopped to end the reaction, and the resultant was centrifuged to collect the sediment, which was vacuum-dried at a low temperature of 45 °C.

Embodiment 3

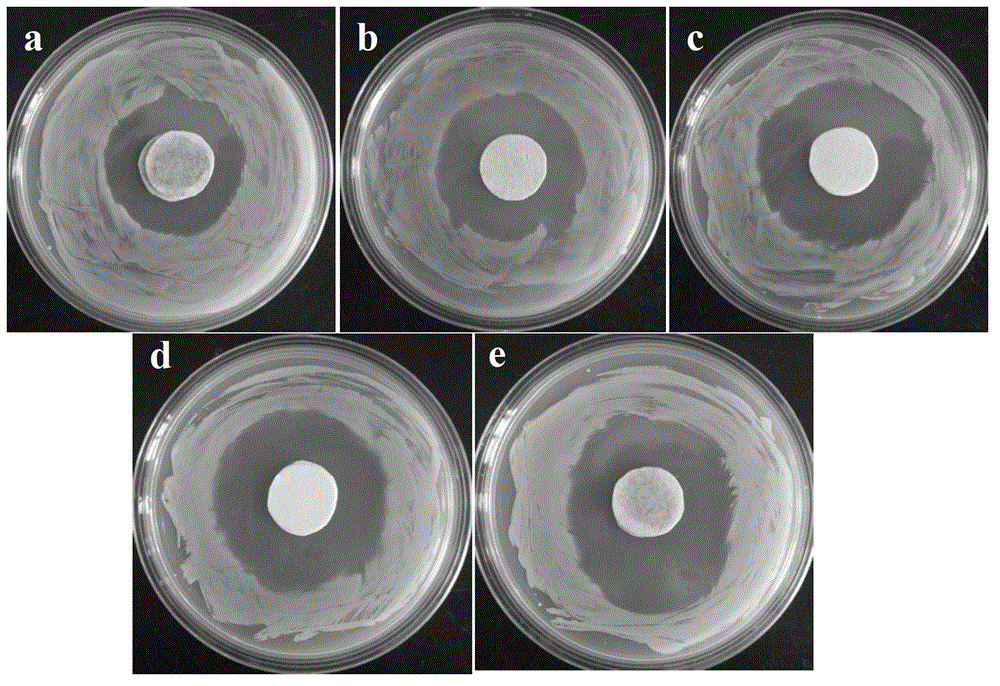

[0026] Example 3 Effect detection

[0027] 1) Take fresh seawater and prepare 2216E medium (taking 1000 mL seawater as an example, the composition is as follows: 5 g peptone, 0.01 g ferric phosphate, 1 g yeast extract, 15-20 g agar. NaOH adjusts the pH value to 7.4-7.6.

[0028] 2) Put the instruments used in the experiment such as watch glasses, glass rods, tweezers, pipettes, sample cotton discs (1.5 cm in diameter) and the prepared medium above in a high-pressure steam sterilizer at 120 Sterilize at ℃ for 30 min.

[0029] 3) Take out the sterilized petri dish and solid medium with a diameter of 9 cm, place them in a sterile operating table, and pour them evenly into a watch glass when the medium is cooled to about 60°C.

[0030] 4) After the medium is solidified, the concentration of viable bacteria is about 8×10 3 CFU / ml of Arthrobacter sulfurus bacteria solution was dripped onto the culture medium, spread evenly on a triangular plate immediately and let stand for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com