Physical model making method and shale model of kerogen-bearing shale based on hot pressing

A production method and a technology of physical models, applied in the field of geophysical research in oil and gas exploration and development, can solve problems such as impact analysis and application, and achieve strong repeatability and stable and reliable production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

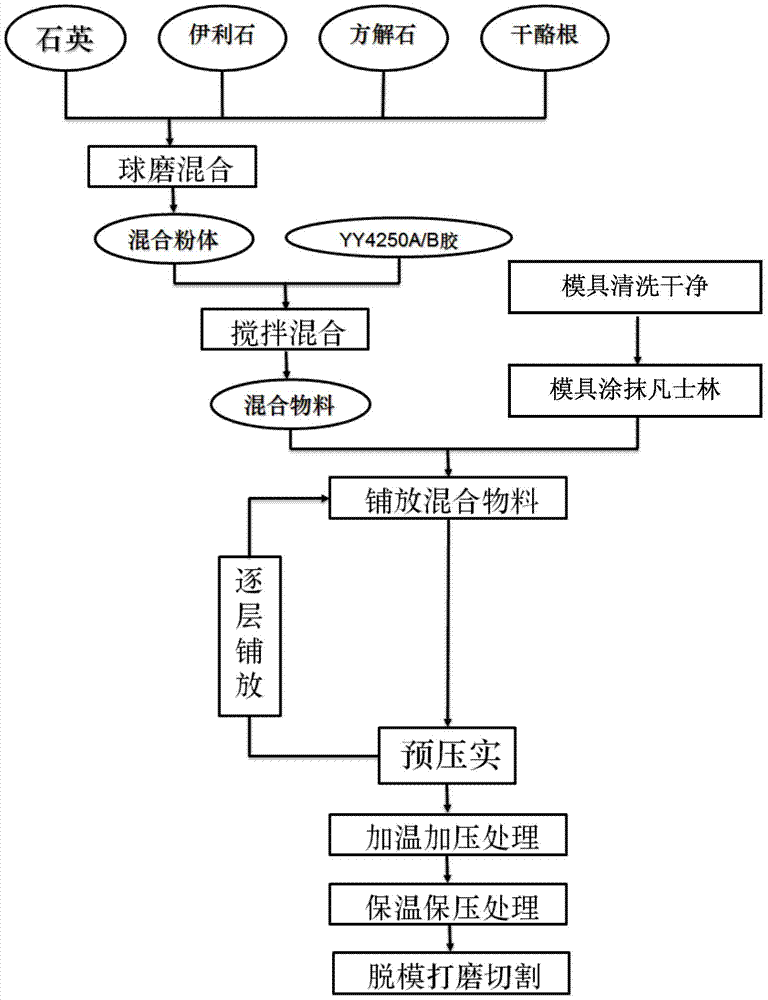

[0057] This embodiment provides a method for making a physical model of kerogen-containing shale based on hot pressing, such as figure 1 As shown, it includes the following steps:

[0058] Put 300g of silicon micropowder with a fineness of 3000 mesh, 250g of illite with a fineness of 4000 mesh, 25g of calcite with a fineness of 4000 mesh and 100g of kerogen in a thermostat at 50°C for 48 hours, then take it out and put it into a ball mill for ball milling and mixing , the ball mill adopts a combination of ball milling beads of large, medium and small sizes, wherein the diameter of the large ball milling beads is 15mm, the diameter of the medium ball milling beads is 12mm, and the diameter of the small ball milling beads is 5mm, and the three sizes of large, medium and small The number ratio of ball milling beads of different sizes is 14:23:84, the rotating speed of the ball mill is 425.4R / min, and the ball milling time is 48h to obtain the mixed powder;

[0059]Add YY4250A / B ...

Embodiment 2

[0071] See Image 6 As shown, it is a structural schematic diagram of a hot-pressing mold for making an artificial rock model provided by a specific embodiment of the present invention, the hot-pressing mold at least includes a mold body 2 and a mold indenter 1; wherein,

[0072] The mold body 2 has a cavity 3 for making an artificial rock model, the bottom of the cavity 3 is provided with a base 7, the cavity 3 and the base 7 are surrounded by a wear-resistant layer 5, and the outer surface of the wear-resistant layer 5 has a bearing The pressure layer 6, the upper surface, the lower surface and the outer surface of the pressure-bearing layer 6 have a heat-insulating layer 13 and are fixedly connected by screws 8, the base 7 and the wear-resistant layer 5 are in close contact, The wear-resistant layer 5 and the pressure-bearing layer 6 are in close contact with the heat-insulating layer 13, and thermocouples 11 and several heaters 12 are arranged in the pressure-bearing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com