Sulfonated poly aryl ether ketone cross-linking membrane containing thioether keys and preparing method thereof

A technology of sulfonated polyaryletherketone and propenylsulfonated polyarylether, which is applied in the field of sulfonated polyaryletherketone cross-linked membrane and its preparation, can solve the problems that it is difficult to have a sufficiently high proton conductivity and cannot be used. Achieve excellent oxidation stability and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

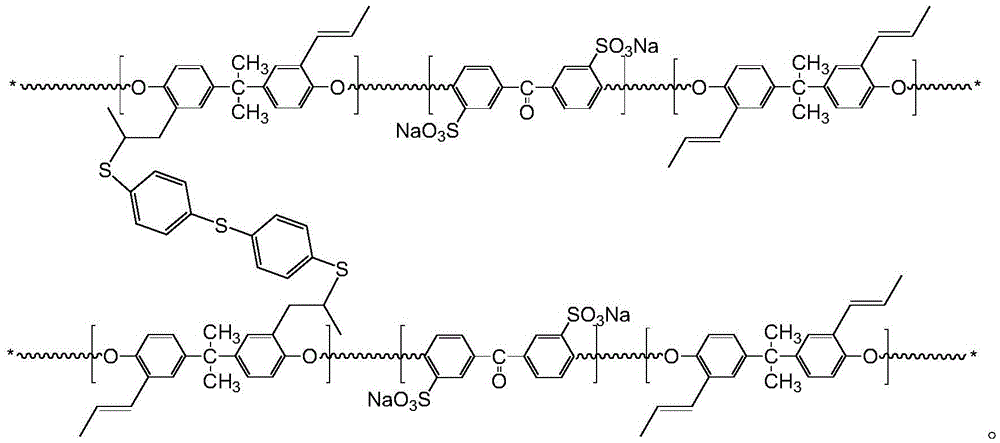

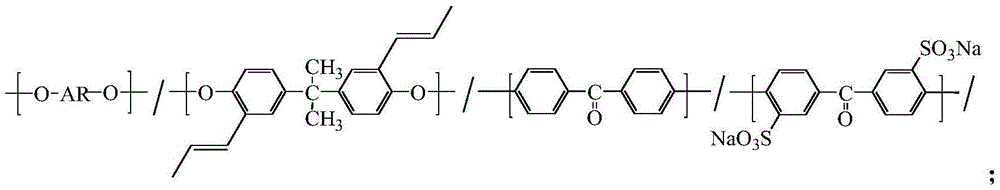

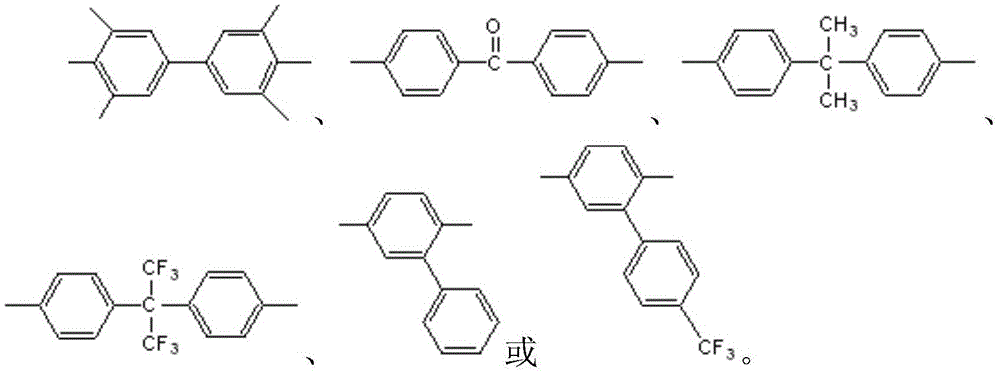

Method used

Image

Examples

Embodiment 1

[0037] In a three-necked flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.02mol of bisphenol A, 0.08mol of diallyl bisphenol A, and 0.02mol of 4,4'- Difluorobenzophenone, 0.08mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 0.11mol of potassium carbonate as a salt-forming agent, and N-methylpyrrolidone as a solvent, Toluene is used as the water-carrying agent, and the solid content is 20%. Bring water at 140°C for 3 hours, then distill off the toluene, raise the temperature to 180°C and continue the reaction for 6 hours. After the reaction was complete, the reactant was poured into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain the propylene group-containing sulfonated polyaryletherketone material.

[0038] The above pr...

Embodiment 2

[0040] In a three-neck flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.1mol of diallyl bisphenol A, 0.04mol of 4,4'-difluorobenzophenone, and 0.06 mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, with 0.115mol of potassium carbonate as a salt-forming agent, sulfolane as a solvent, and xylene as a water-carrying agent, with a solid content of 30%. Bring water at 140°C for 3 hours, then distill off the xylene, then raise the temperature to 180°C to continue the reaction for 6 hours. After the reaction was complete, the reactant was poured into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain the propylene group-containing sulfonated polyaryletherketone material.

[0041] The acrylic sulfonated polyaryletherketone matrix is ...

Embodiment 3

[0043] In a three-necked flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.04mol of tetramethylbiphenol, 0.06mol of diallyl bisphenol A, and 0.05mol of 4 , 4'-difluorobenzophenone, 0.05mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 0.12mol of potassium carbonate as a salt-forming agent, and dimethylformaldehyde Amide is used as solvent, toluene is used as water carrier, and the solid content is 20%. Bring water at 130°C for 3 hours, then distill off the toluene, raise the temperature to 150°C and continue the reaction for 10 hours. After the reaction was complete, the reactant was poured into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain a propylene group-containing sulfonated polyaryletherketone material.

[0044] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap