Bridge abutment structure capable of preventing bumping at bridge head and preventing method

A bridge head jumping and abutment technology, which is applied to bridges, bridge parts, bridge maintenance and other directions, can solve problems such as height difference, bridge head jumping, settlement difference, etc., to achieve simple structure design, prevent bridge head jumping, and eliminate bridge head. The effect of differential settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

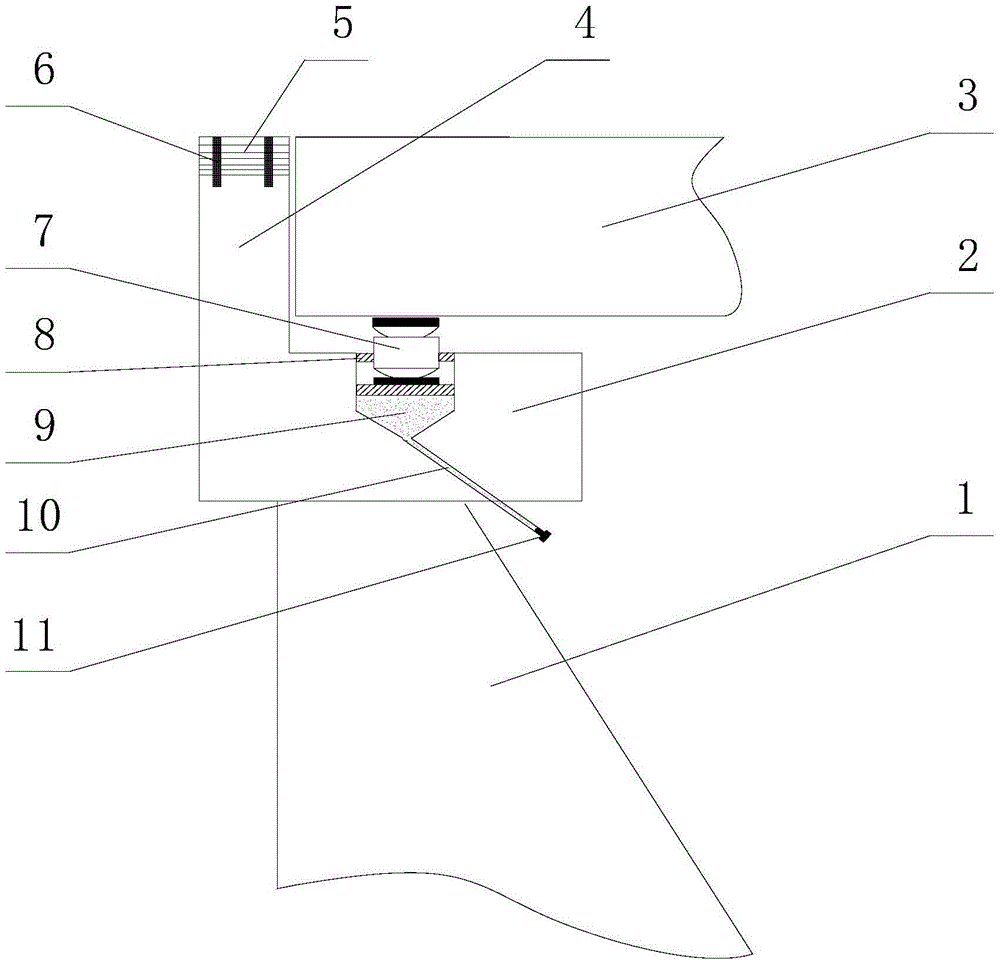

[0022] Depend on figure 1 It can be seen that the abutment structure of the present embodiment that can prevent vehicle jumping at the bridge head is composed of platform cap 2, back wall 4, adjustment plate 5, adjustment anchor bolt 6, sand 9, pendulum type support 7, elastic filling layer 8, row The sand pipe 10 and the plug 11 are combined.

[0023] The abutment of this embodiment is located at the end of the bridge 3, the abutment is made up of a platform cap 2 and a back wall 4, the platform cap 2 is horizontally installed on the pier 1, and the back wall 4 is vertically installed on one side of the platform cap 2, for It is convenient to adjust the height of the back wall 4. On the top of the back wall 4, 10 layers of steel plates are stacked as the adjustment plate 5. The thickness of each layer of the adjustment plate 5 is 4cm, and the length and width are the same as the size of the back wall 4. On the adjustment plate 5, there are screw hole, and pass the screw hole...

Embodiment 2

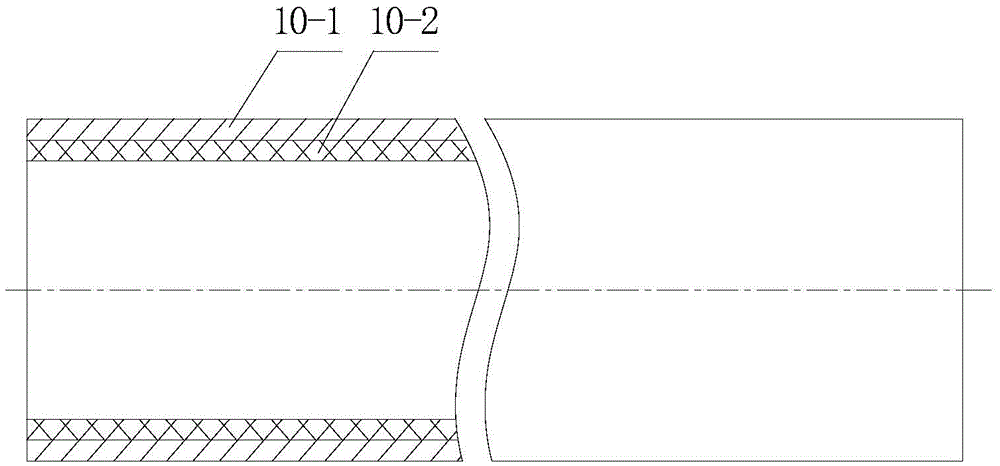

[0030] The abutment of this embodiment is located at the end of the bridge 3, the abutment is made up of a platform cap 2 and a back wall 4, the platform cap 2 is horizontally installed on the pier 1, and the back wall 4 is vertically installed on one side of the platform cap 2, for It is convenient to adjust the height of the back wall 4. On the top of the back wall 4, 5 layers of steel plates are laminated as the adjustment plate 5. The thickness of each layer of adjustment plates 5 is 5 cm, and the length and width are the same as the size of the back wall 4. In order to ensure smooth sand discharge , An included angle of 20° is formed between the central axis of the sand discharge pipe 10 and the central axis of the borehole.

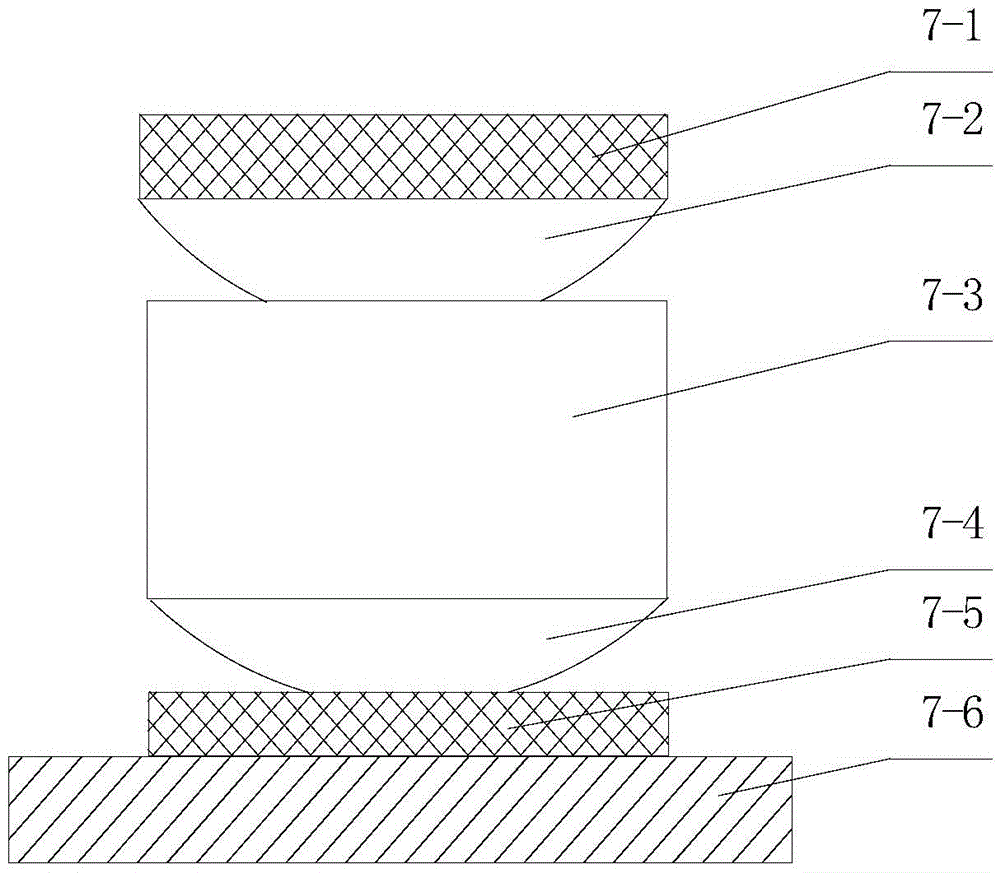

[0031] In order to prevent the pendulum support 7 from tilting left and right in the well, the gap between the pendulum support 7 and the inner wall of the well is filled with an elastic filling layer 8. The elastic filling layer 8 can be made of rub...

Embodiment 3

[0037] The abutment of this embodiment is located at the end of the bridge 3, the abutment is made up of a platform cap 2 and a back wall 4, the platform cap 2 is horizontally installed on the pier 1, and the back wall 4 is vertically installed on one side of the platform cap 2, for It is convenient to adjust the height of the back wall 4. On the top of the back wall 4, 6 layers of steel plates are stacked as the adjustment plate 5. The thickness of each layer of the adjustment plate 5 is 3cm, and the length and width are the same as the back wall 4. In order to ensure smooth sand discharge , An included angle of 60° is formed between the central axis of the sand discharge pipe 10 and the central axis of the borehole.

[0038] In order to prevent the pendulum support 7 from tilting left and right in the well, the gap between the pendulum support 7 and the inner wall of the well is filled with an elastic filling layer 8. The elastic filling layer 8 can be made of rubber or Polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com