Highway bridge abutment wedge flexible attachment strap

A wedge-shaped flexible, highway bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficult control of expansion speed, and achieve the effect of high rigidity, low engineering cost and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

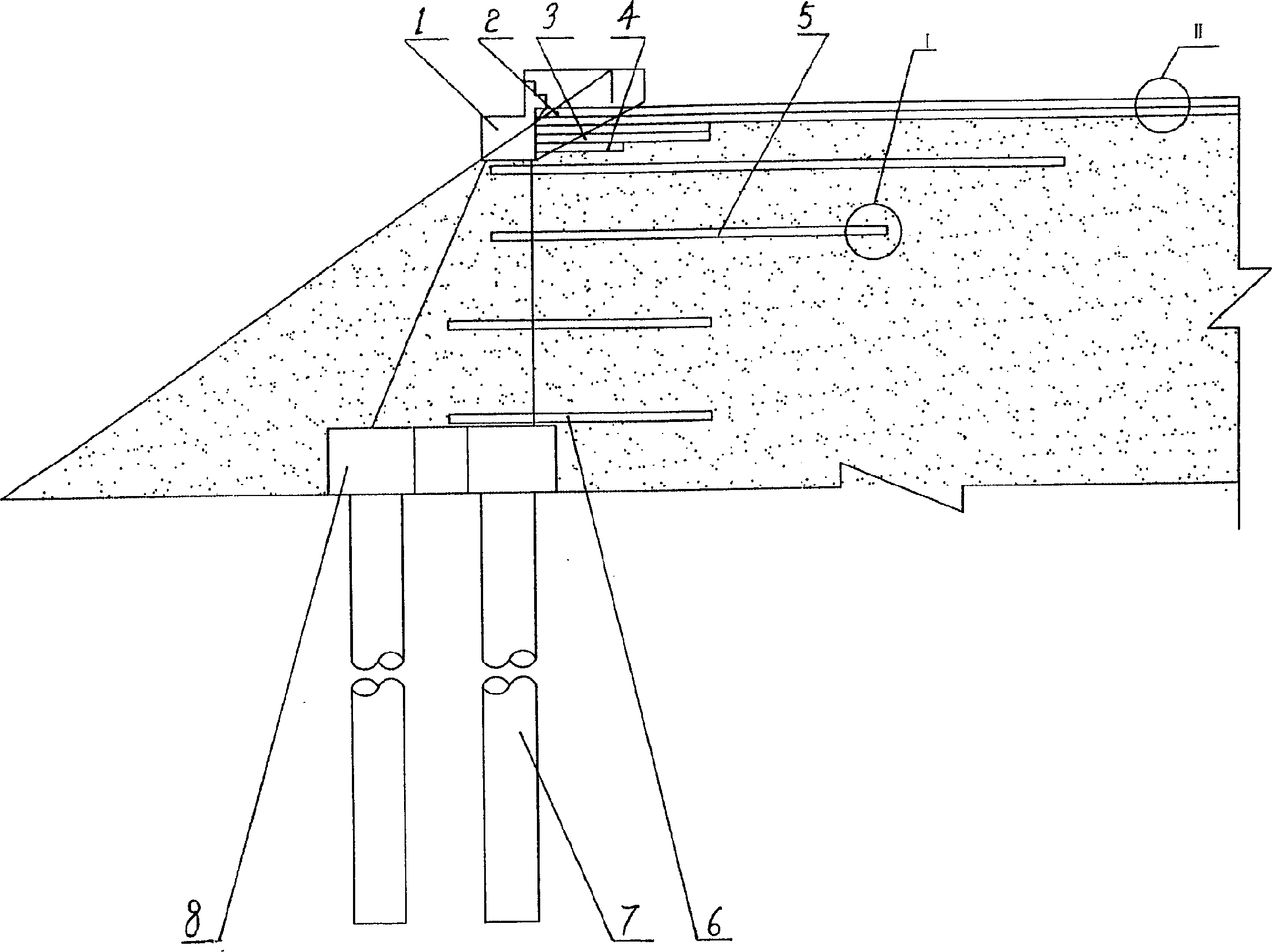

[0028] figure 1 A schematic structural diagram of Embodiment 1 of the present invention is given. exist figure 1 , Figure 5 In ~8, the highway bridge abutment wedge-shaped flexible lap of the present embodiment consists of an upper double-layer geocell 2, a lower double-layer geocell 3, a top layer single-layer geocell 4, an intermediate layer single-layer geocell 5, Bottom single-layer geocell 6, connecting ear 11, connecting pin 12 constitute.

[0029] The abutment 1 is connected with an upper double-layer geocell 2, a lower double-layer geocell 3, and a top single-layer geocell 4, and the length of the upper double-layer geocell 2 is greater than that of the lower double-layer geocell 3 , the length of the lower double-layer geocell 3 is greater than the length of the top single-layer geocell 4 . The lower double-layer geocell 3 and the top single-layer geocell 4 constitute the flexible support of the abutment 1 . A bottom single-layer geocell 6 is arranged on the cap...

Embodiment 2

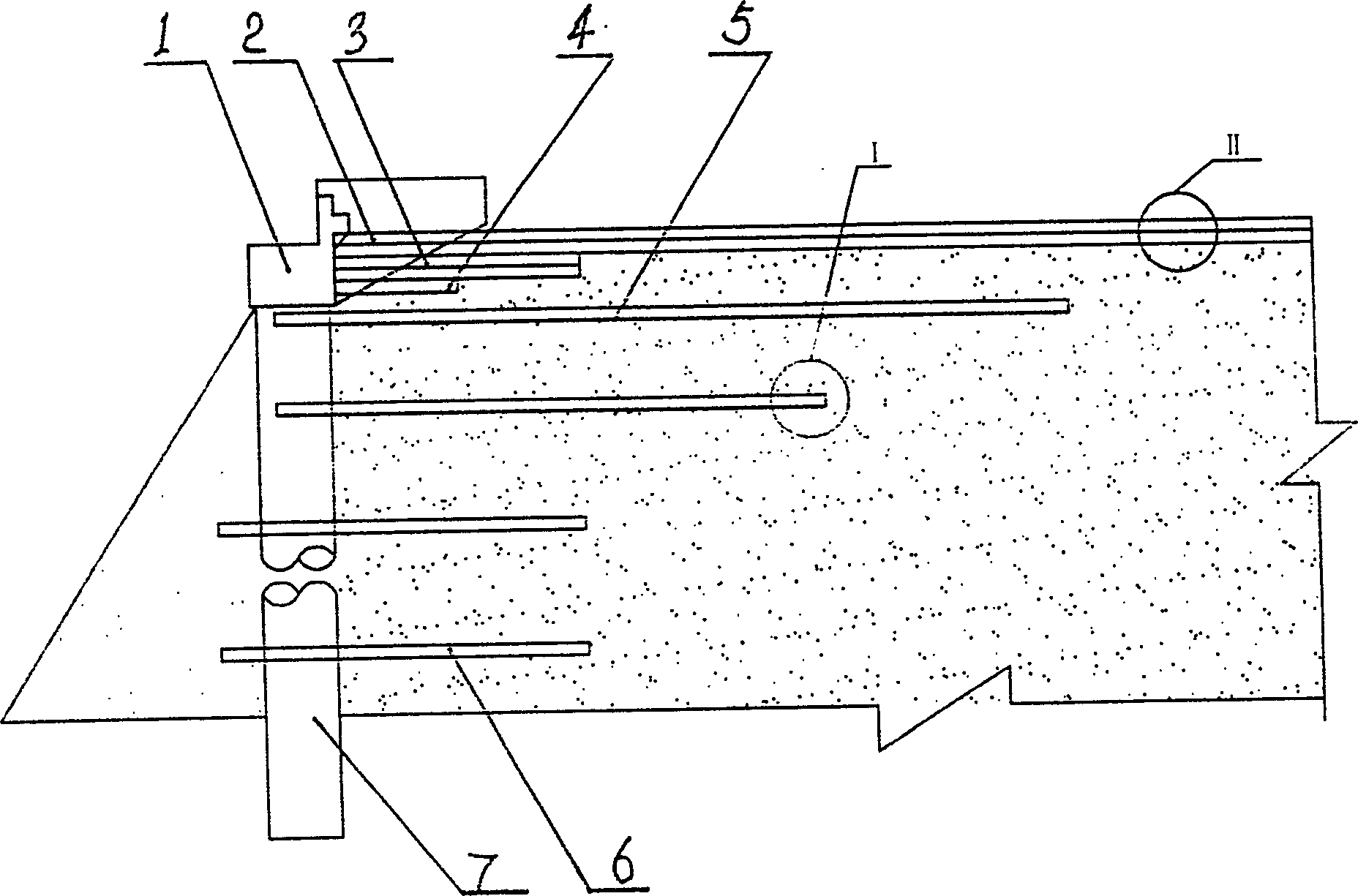

[0035] figure 2 , 5 ~8 shows the schematic structural diagram of Embodiment 2 of the present invention. exist figure 2 , 5 In ~8, the highway bridge abutment wedge-shaped flexible lap of the present embodiment consists of an upper double-layer geocell 2, a lower double-layer geocell 3, a top layer single-layer geocell 4, an intermediate layer single-layer geocell 5, Bottom single-layer geocell 6, connecting ear 11, connecting pin 12 constitute.

[0036] The connection relationship between the upper double-layer geocell 2 , the lower double-layer geocell 3 , the top single-layer geocell 4 and the abutment 1 is the same as that in Embodiment 1, and the top of the pile 7 is connected with the abutment 1 as a whole. The bottom single-layer geocell 6 is arranged on the bottom foundation, and the middle single-layer geocell 5 between the bottom single-layer geocell 6 and the top single-layer geocell 4 is the same as that in Embodiment 1.

[0037] The structure of the upper do...

Embodiment 3

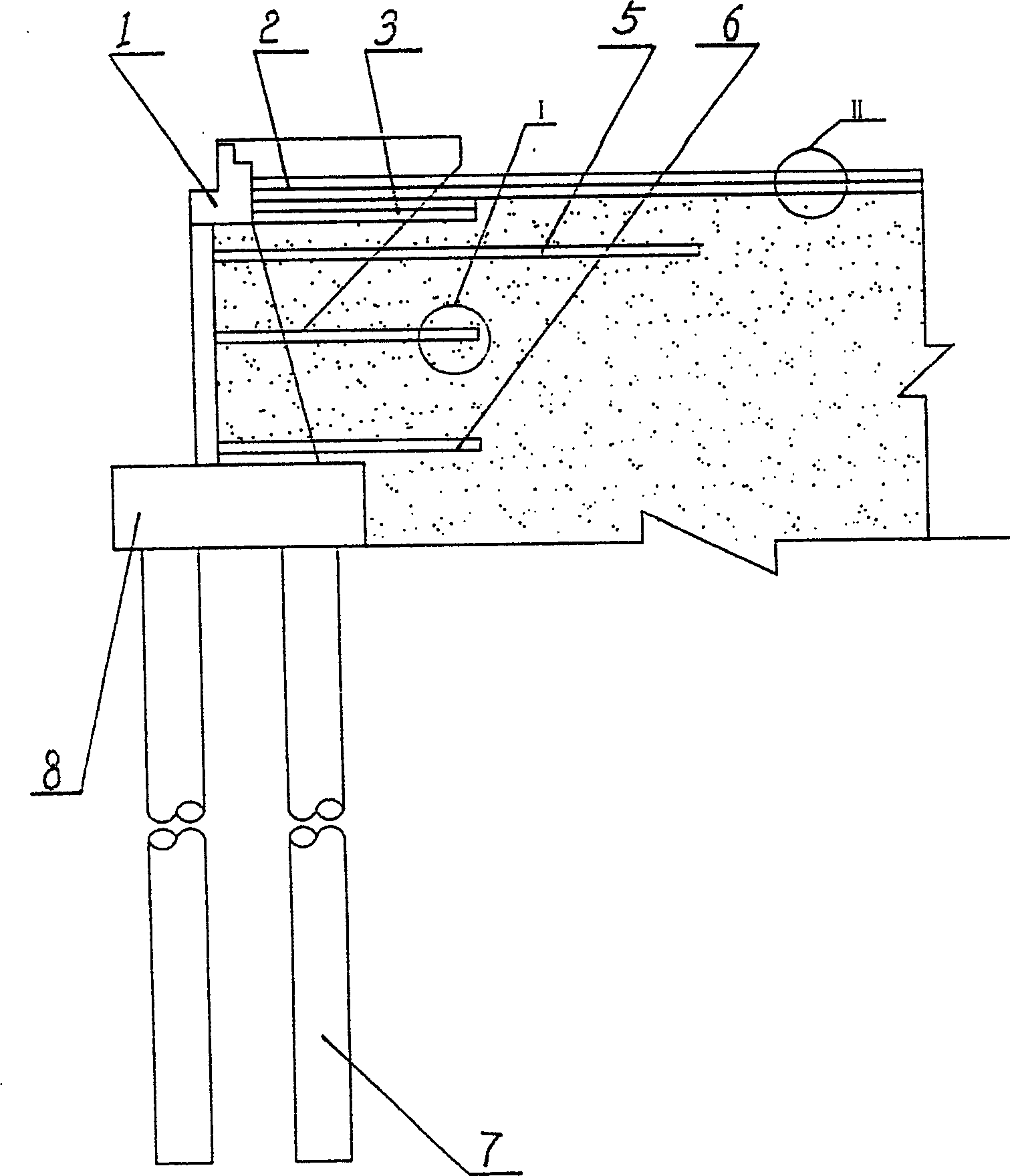

[0039] image 3 A schematic structural diagram of Embodiment 3 of the present invention is given. exist image 3 , Figure 5 In ~8, the highway bridge abutment wedge-shaped flexible slab of the present embodiment consists of an upper double-layer geocell 2, a lower double-layer geocell 3, a middle layer single-layer geocell 5, a bottom single-layer geocell 6, Connecting ear 11, connecting pin 12 constitute.

[0040] The abutment 1 is connected with an upper double-layer geocell 2 and a lower double-layer geocell 3, the length of the upper double-layer geocell 2 is greater than that of the lower double-layer geocell 3, and the lower double-layer geocell 3 It constitutes the flexible support of the abutment 1. The bottom single-layer geocell 6 is arranged on the cap 8 connected with the pile 7, and two layers of intermediate single-layer geocells are arranged between the lower double-layer geocell 3 and the bottom single-layer geocell 6 Chamber 5, the bottom layer of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com