Shock-insulating elastic returning mechanism with preset starting load and start-control shock insulating equipment with preset starting load

An elastic reset and start-up control technology, applied in mechanical equipment, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve problems such as defective reset function of elastic reset device, equipment vibration isolation problem, and deformation space limitation of vibration isolation device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

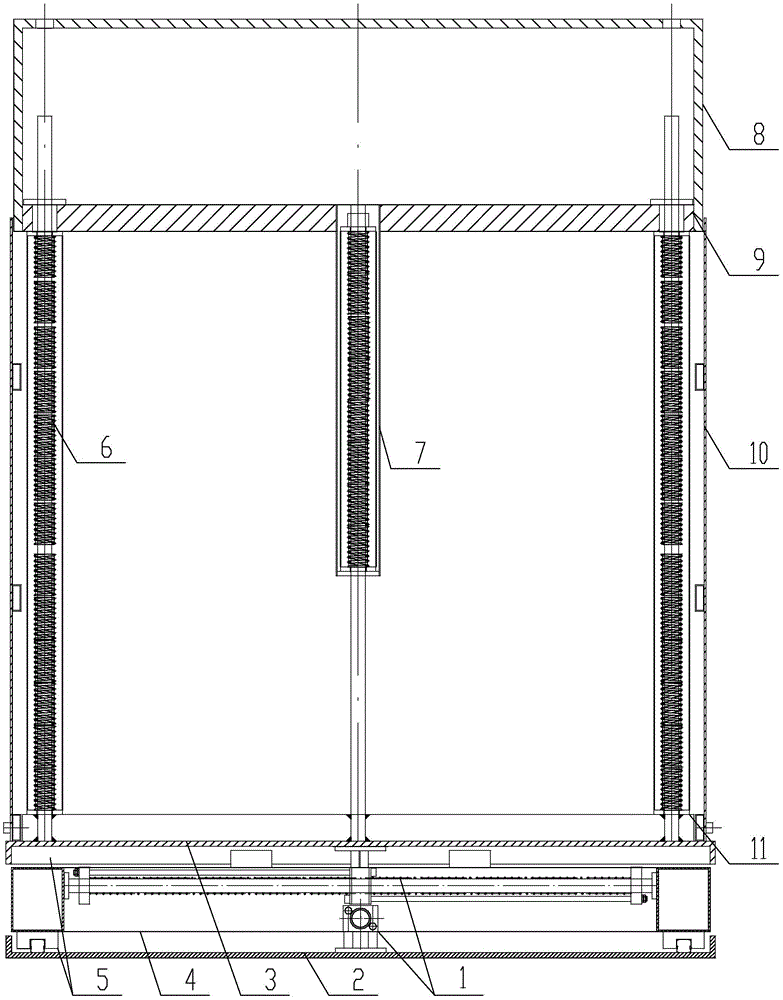

[0082] The embodiment of the start-up control shock-isolation device of the preset start-up load of the present invention is as follows Figure 1 to Figure 17 As shown, the device includes an upper panel 3, a lower panel 2, a middle frame 4 and a shock-isolation elastic reset device with a preset starting load. The lower panel 2 is used to be placed on the floor or showcase panel or the ground. The upper panel 3 and the lower panel 2 are equipped with a wiring area 101 for power lines or data lines to pass through. The shock-isolation elastic reset device includes two sets of horizontal shock-isolation elastic reset mechanisms 1 and five sets of vertical shock-isolation elastic reset mechanisms 6. The elastic return mechanism 6 is located above the device. The device has both a horizontal shock-isolation elastic return mechanism 1 and a vertical shock-isolation elastic return mechanism 6, which can be combined to realize vertical and horizontal three-dimensional shock isolation...

Embodiment 2

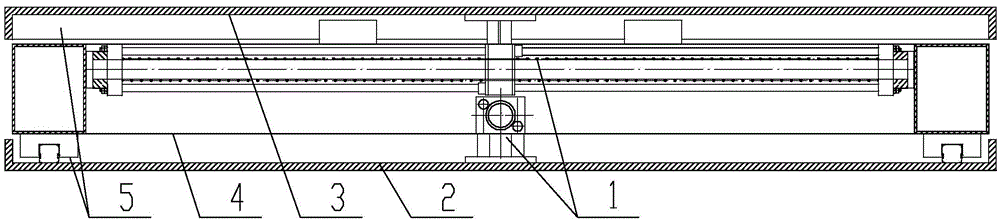

[0114] The second embodiment of the start-up control shock-isolation device with preset start-up load in the present invention is as follows Figure 18 to Figure 20 As shown, the difference from Embodiment 1 is that the shock-isolation elastic return device of this embodiment only includes a horizontal shock-isolation elastic return mechanism, and does not provide a vertical shock-isolation elastic return mechanism, while omitting the connecting plate and the upper cavity.

[0115] In this embodiment, two sets of horizontal shock-isolation elastic return mechanisms are provided in the horizontal and vertical directions respectively, and four sets of horizontal shock-isolation elastic return mechanisms are erected on the side of the middle frame 4 in the shape of a well-shaped cross along the horizontal and vertical lines. Both ends of the shock-isolation elastic reset mechanism are fixedly connected with the middle frame 4 through guide rods 13, the first slider 16 in the horiz...

Embodiment 3

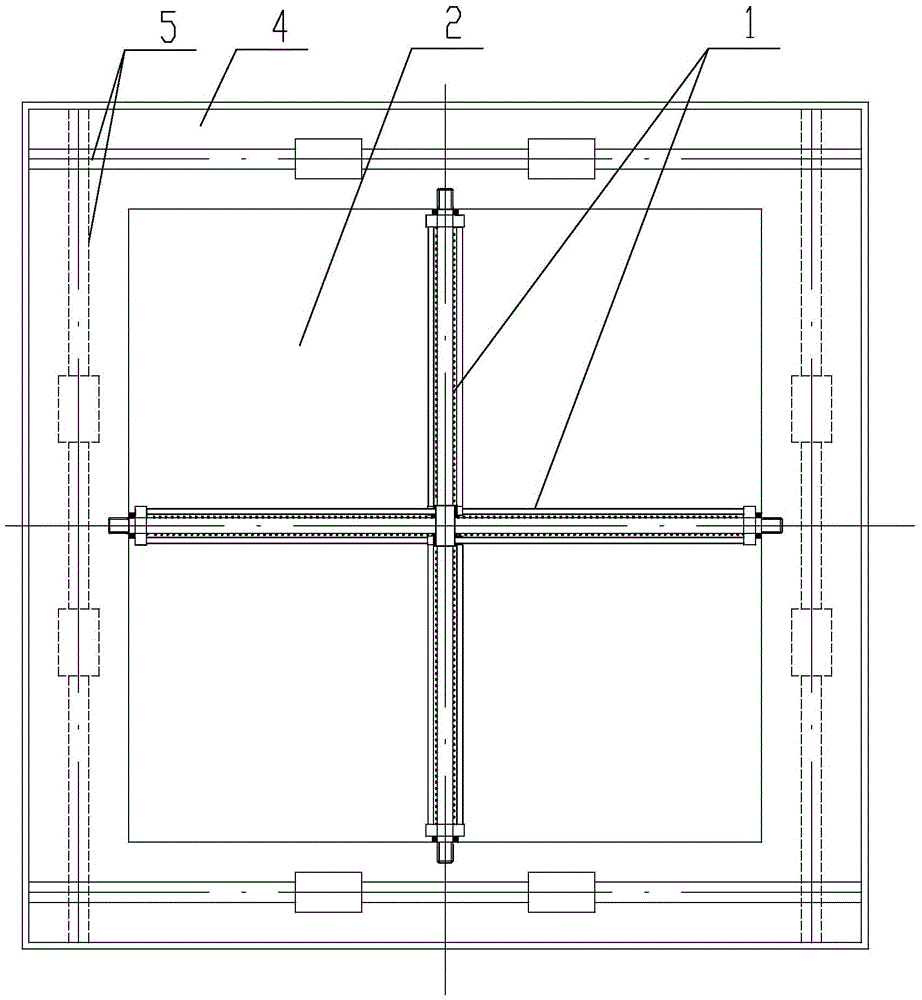

[0117] The third embodiment of the start-up control shock-isolation equipment with preset start-up load in the present invention is as follows Figure 21 to Figure 23 As shown, the difference from Embodiment 1 is that the shock-isolation elastic return device of this embodiment only includes a horizontal shock-isolation elastic return mechanism, and does not provide a vertical shock-isolation elastic return mechanism, while omitting the connecting plate and the upper cavity.

[0118] In this embodiment, the shock-isolation elastic reset mechanism is a horizontal shock-isolation elastic reset mechanism, and there are one set of horizontal shock-isolation elastic reset mechanisms along the horizontal and vertical directions. The horizontal shock-isolation elastic reset mechanism includes guide rod 13, stopper 15, spiral steel Spring 12, steel strand 22 and second slide block 23, guide rod 13 are horizontally arranged, and second slide block 23 is sleeved in the middle part of gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com