Novel valve side wire-outlet structure for converter transformer

A converter transformer and valve side technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve design inconvenience, supply shortage, design, process, manufacturing To solve problems such as complicated process, achieve the effect of easy realization, reasonable structure, and ease the tight supply situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

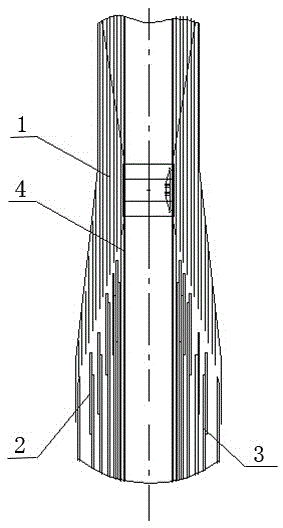

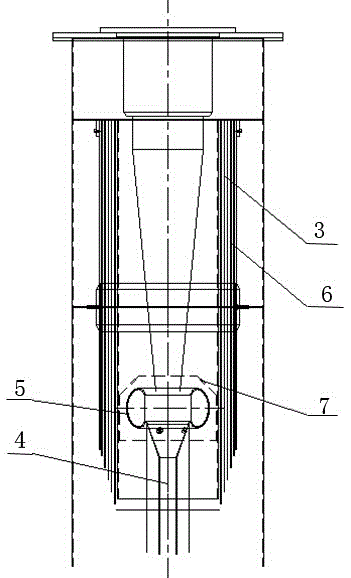

[0016] The new valve-side outlet structure of the converter transformer uses aluminum tube 4 for insulation at the outlet of the valve-side leads of the converter transformer, and adopts a structure of multi-layer insulating paper tube 3 and corrugated cardboard 6 at the outlet, gradually transitioning to a structure of crepe paper 1;

[0017] Install multi-layer insulating paper tubes and corrugated cardboard outside the aluminum tube at the outlet. The insulating paper tubes of each layer are overlapped from the inside to the outside. The length of the inner insulating paper tube is greater than the length of the outer insulating paper tube. The tubes are overlapped at even intervals; corrugated cardboard is arranged between adjacent two layers of insulating paper tubes, and the length of the corrugated cardboard is longer than that of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com