Sugarcane leaf fiber rubbing and pressing device

A leaf and fiber technology, which is applied in the field of sugarcane leaf fiber rubbing and pressing equipment, can solve the problems of waste and large sugarcane leaf output, and achieve the effects of alleviating supply tension, maintaining normal operation, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

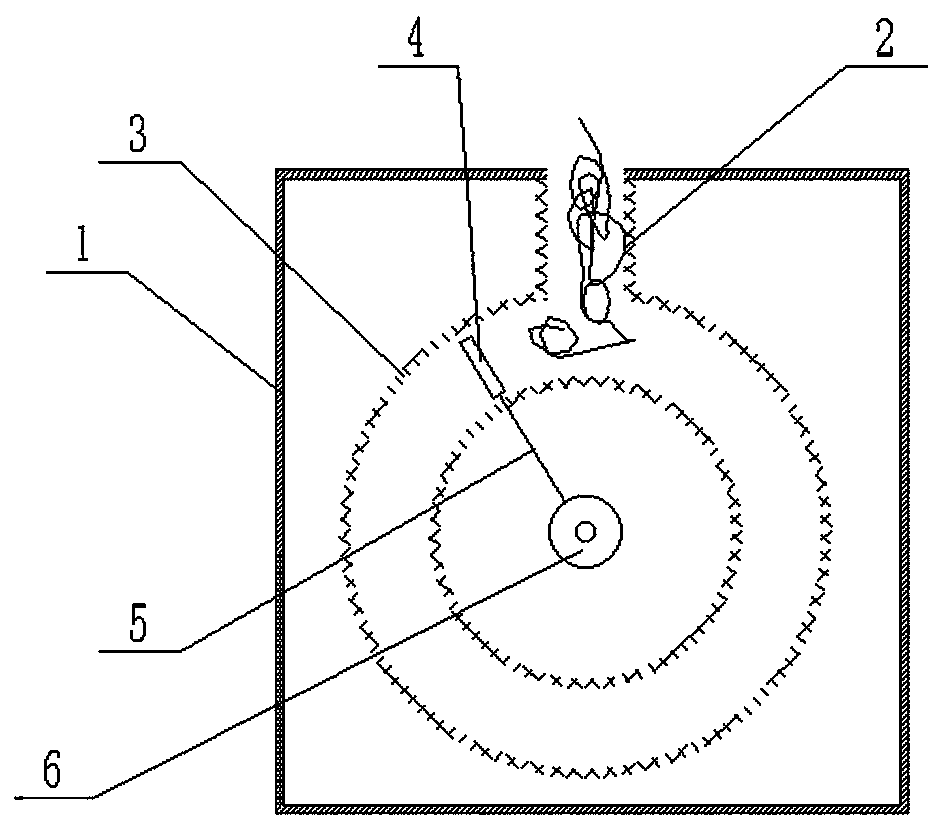

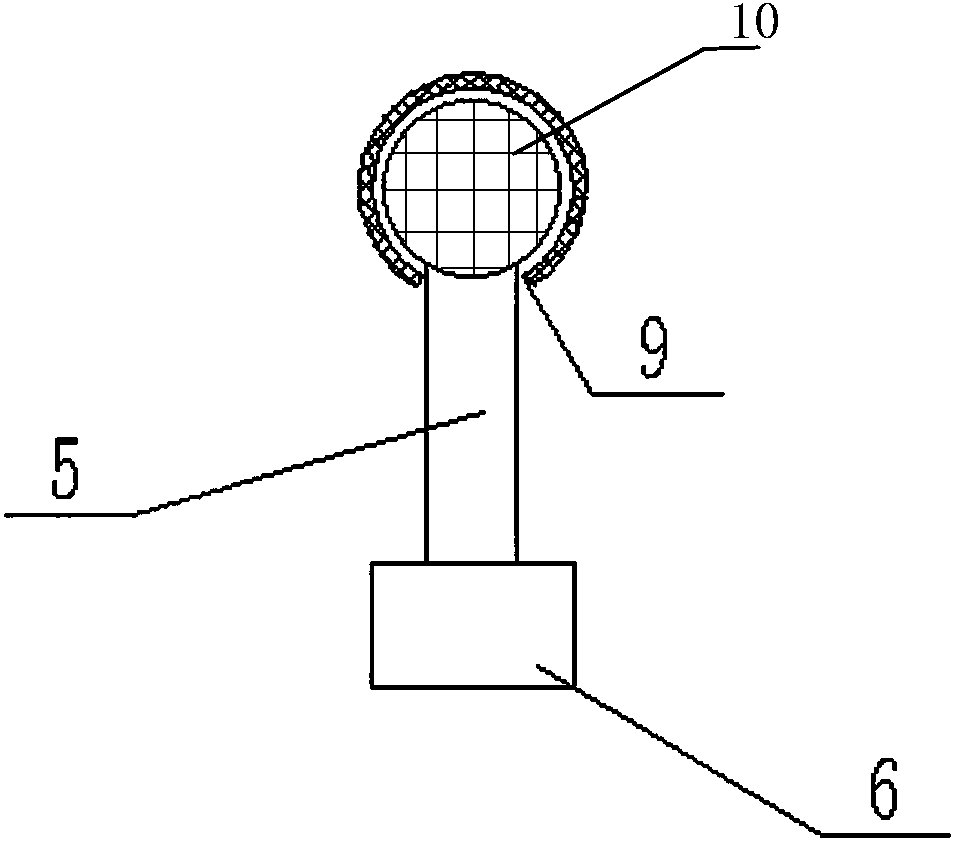

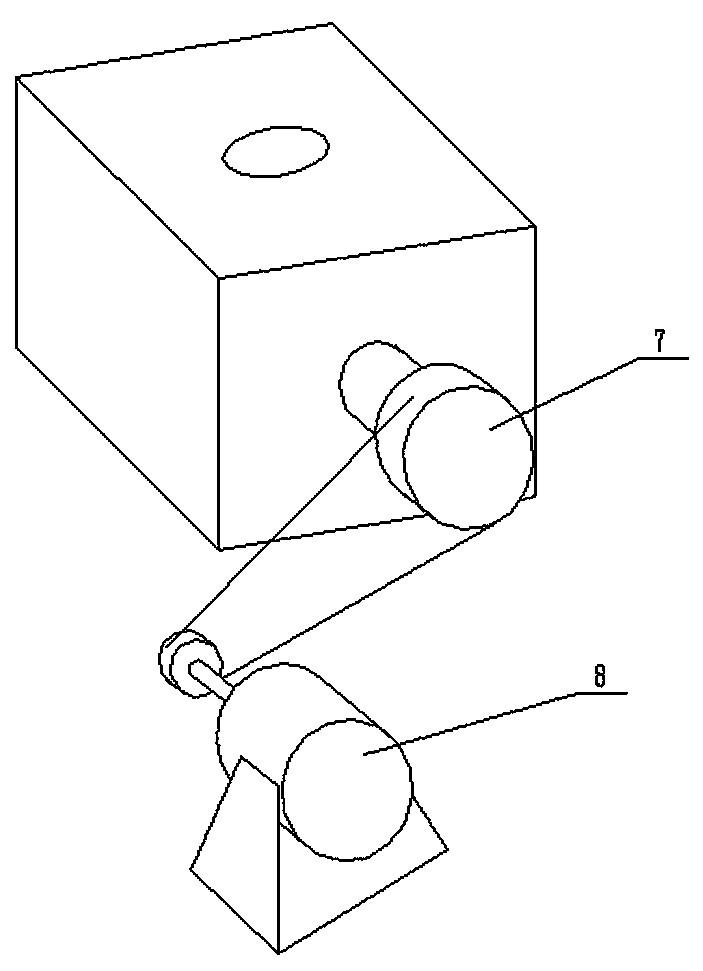

[0010] figure 1 , 2 , 3 middle: shell 1, feeding port 2, kneading and pressing channel 3, cycle shifting gear 4, shifting rod 5, rotating shaft 6, transmission mechanism 7, motor 8, gap 9, steel wire mesh 10.

[0011] A kneading and squeezing device for sugarcane leaf fibers, the kneading and squeezing device includes a shell 1 provided with a feed inlet 2, a kneading and squeezing channel 3, a circulation shifter 4, a toggle rod 5, and a rotating shaft 6, and the rotating shaft 6 is connected to the The casing 1 is movably connected, one end of the rotating shaft 6 is connected to the motor 8 through the transmission mechanism 7, the cycle shifter 4 is fixedly connected to one end of the toggle lever 5, and the other end of the toggle lever 5 is connected to the The rotating shaft 6 is fixedly connected, the kneading and squeezing channel 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com