Hot start ballast and low-frequency full bridge circuit of metal halide lamp

A full-bridge circuit, hot-start technology, applied in the power supply field, can solve the problem of short service life of LED lamps, and achieve the effect of ensuring the service life, reducing the conducted EMI noise ratio, and realizing the effect of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding and understanding of the structure, features and effects of the invention, a preferred embodiment is now given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

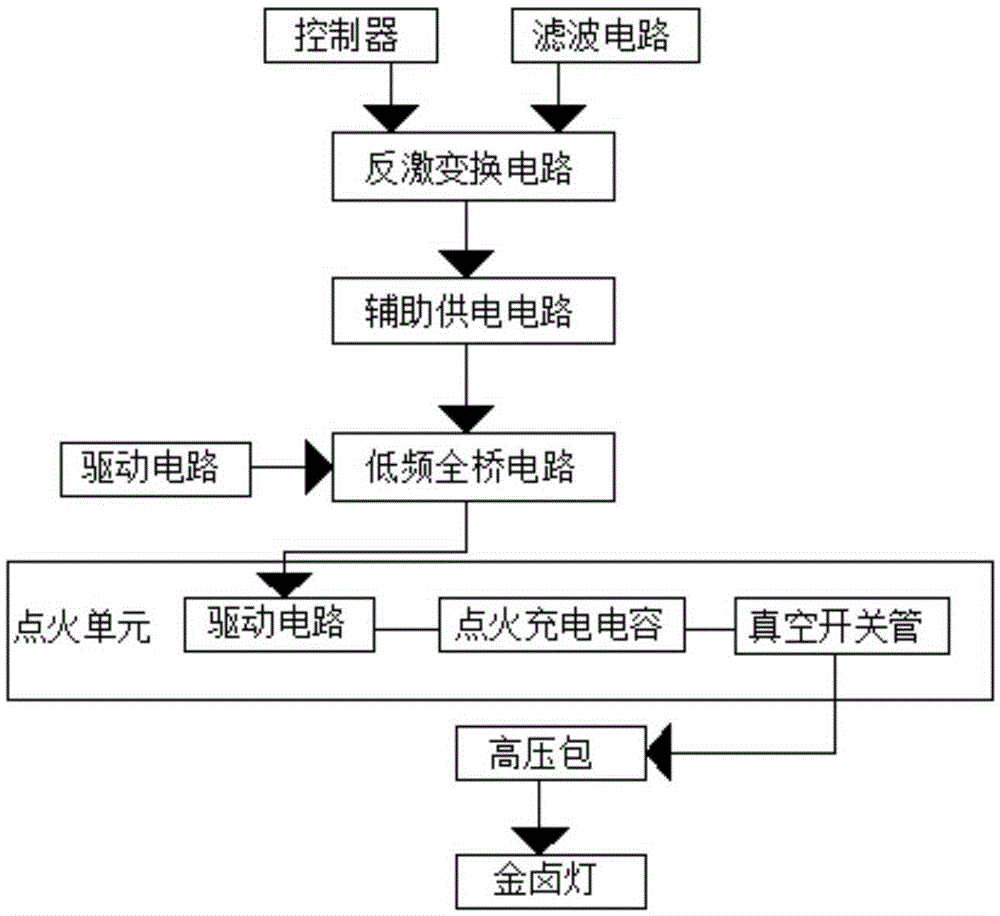

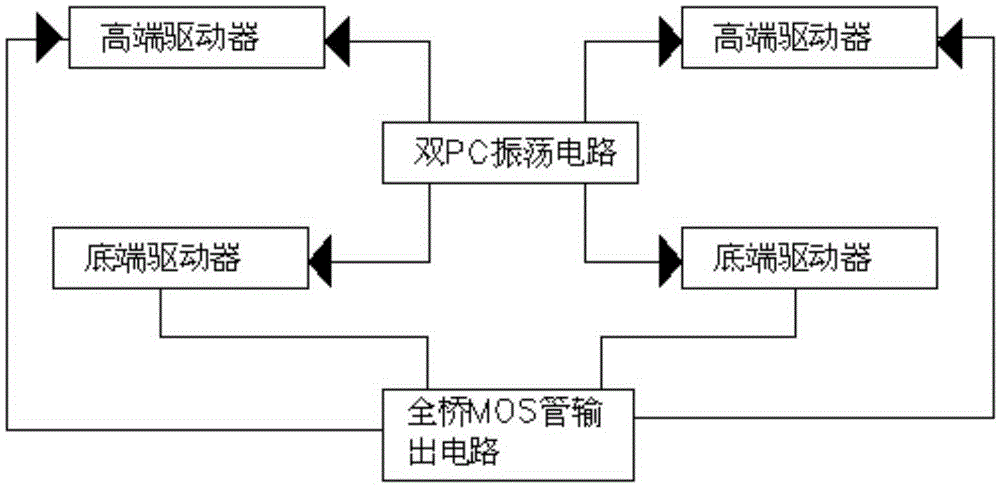

[0014] Such as figure 1 and figure 2 As shown, a metal halide lamp hot-start ballast and low-frequency full-bridge circuit described in this embodiment mainly includes a filter circuit 2, a flyback conversion circuit 3, a controller 1, an auxiliary power supply circuit 4, and a low-frequency full-bridge circuit. The circuit 5, the drive circuit 6 and the ignition unit 12, the input terminal of the filter circuit 2 is connected to the low-voltage DC input power supply, the other output terminal is connected to the flyback conversion circuit, the controller 1 is connected to the flyback conversion circuit 3, and the auxiliary power supply The output terminal of the circuit 4 is connected with the low-frequency full-bridge circuit 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com