Electric cooker

A technology for an electric cooker and a cooker body, which is applied to heating devices, cooking utensils, household appliances, etc., can solve the problems of increasing the heat insulation requirements of related parts of the rice cooker, the inability to accurately control the amount of steam, and the inability to control the amount of steam. Low, easy to add water, easy to use and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

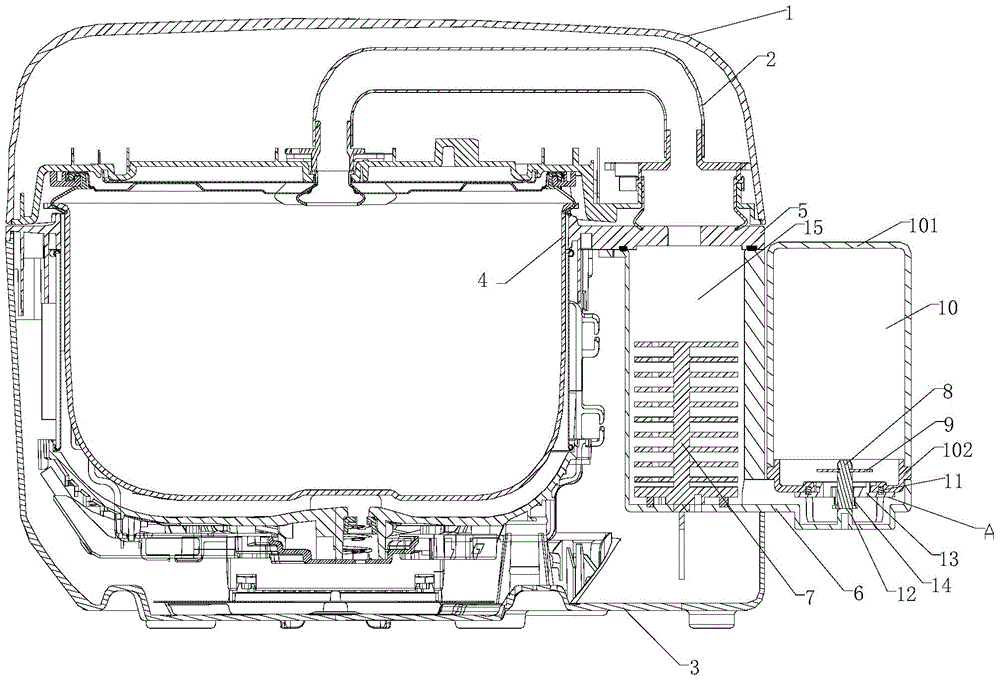

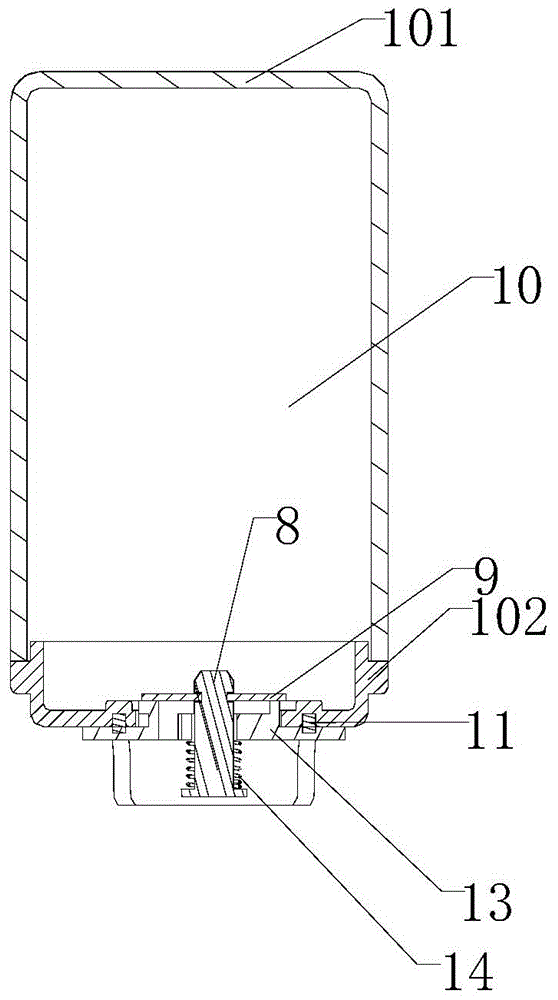

[0028] refer to figure 1 , figure 2 , an electric rice cooker, which includes a pot body and an inner pot 4 put into the pot body, the pot body includes a base 3 and a cover 1 covering the base 3 and covering the aforementioned inner pot 4, the pot body is provided with a A steam generating device for high-temperature steam, and a steam introducing pipe 2 communicating with the steam generating device to introduce high-temperature steam into the inner pot, the steam generating device is arranged in the base 4 , and the steam introducing pipe 3 is arranged in the surface cover 1 . The present invention generates high-temperature steam after atomizing the water through the steam generating device, and the high-temperature steam is introduced into the inner pot 4 through the steam introduction pipe 2, so as to prevent the upper layer of rice in the inner pot 4 from drying, promote the gelatinization of the rice, and improve the performance of cooking rice. After the steam gener...

Embodiment 2

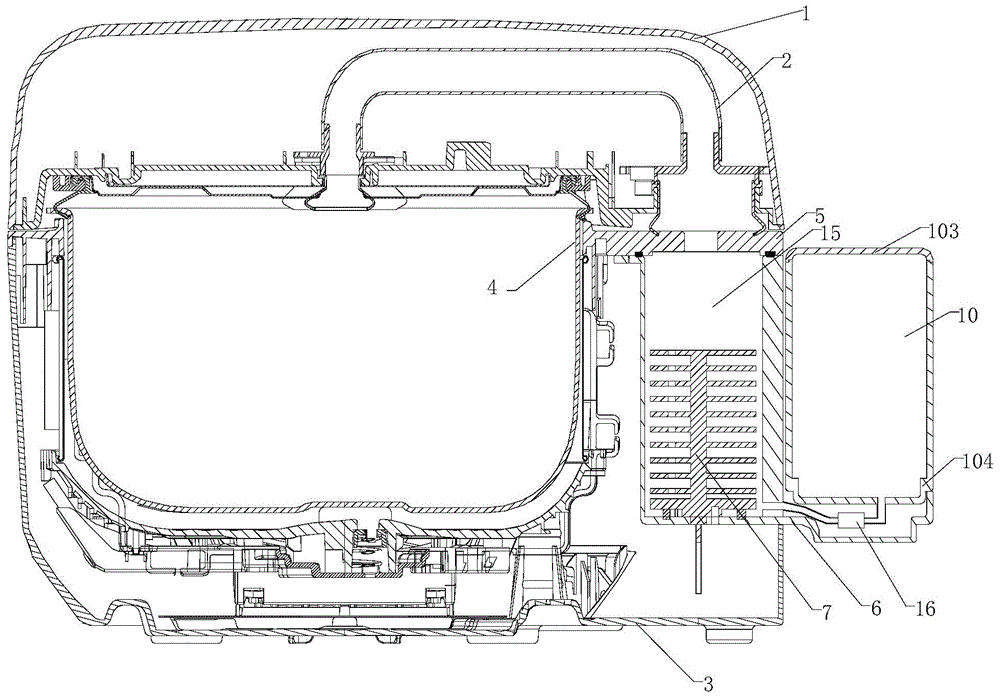

[0039] refer to image 3 The difference between the present embodiment and the first embodiment is that a solenoid valve 16 is provided between the water outlet of the water container 10 and the water inlet of the accommodating cavity 15 to control the amount of water entering the accommodating cavity 15 from the water container 10 , ensure that the water yield is not over the bottom of the heating device 7. The water container 10 is made up of a cup cover 103 and a cup body 104 , the cup cover 103 can be opened to add water to the water container 104 , and the water outlet is arranged at the bottom of the cup body 104 . The water container 10 in this embodiment can be filled with water without taking it off, which is convenient and quick. The rest of the structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com