Steam atomizing spray gun

A technology for atomizing spray guns and steam, which is applied to spray devices, liquid spray devices, etc., can solve the problem of not being able to use saturated steam, and achieve the effect of preventing high temperature damage and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

[0015] The invention discloses a steam atomization spray gun. The steam atomization spray gun can mix saturated steam and water outside the nozzle to atomize the steam and cool down the gas.

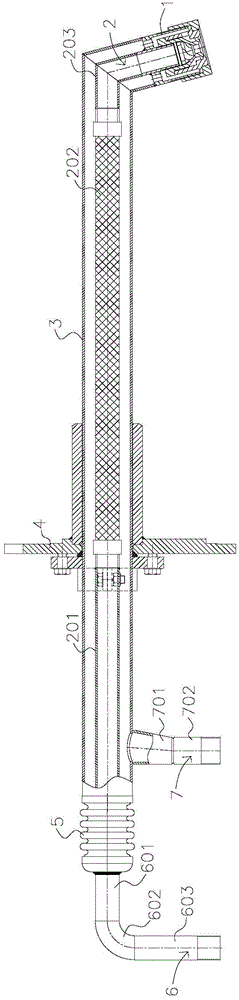

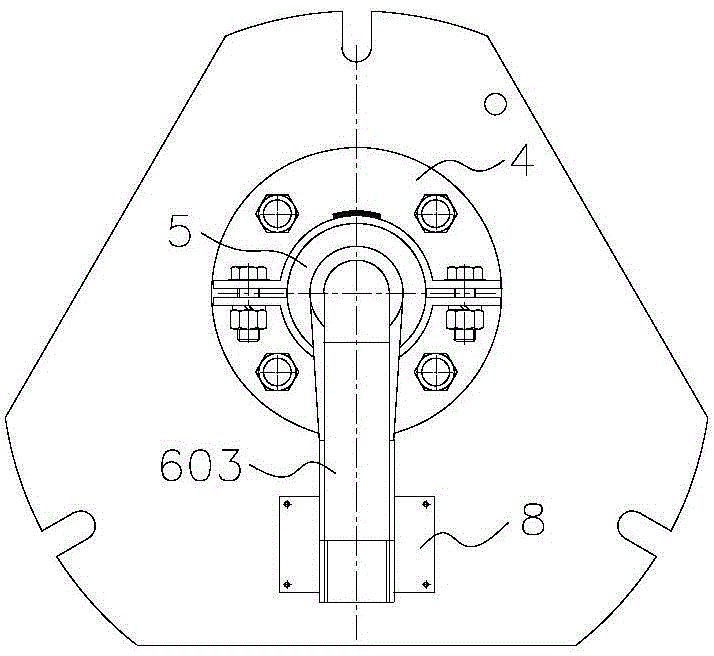

[0016] see figure 1 , figure 2 , the steam atomizing spray gun of the present invention includes an inner pipe 2 and an outer pipe 3 sleeved outside the inner pipe 2 . The inner pipe 2 and the first end of the outer pipe 3 ( figure 1 The left end of the middle) is connected with the head 5, and the second end ( figure 1 The right end in the center) is connected with a nozzle 1, and a hollow area (not shown in the figure) is formed between the inner pipe 2 and the outer pipe 3. The head 5 is connected with a water input pipe 6 communicating with the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com