Novel magnet assembling and pressing jig

A technology for pressing jigs and magnets, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficult to determine the pressing pressure, poor positioning and assembly accuracy, low assembly efficiency, etc., to reduce the labor intensity of workers, The effect of high positioning and assembly accuracy and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

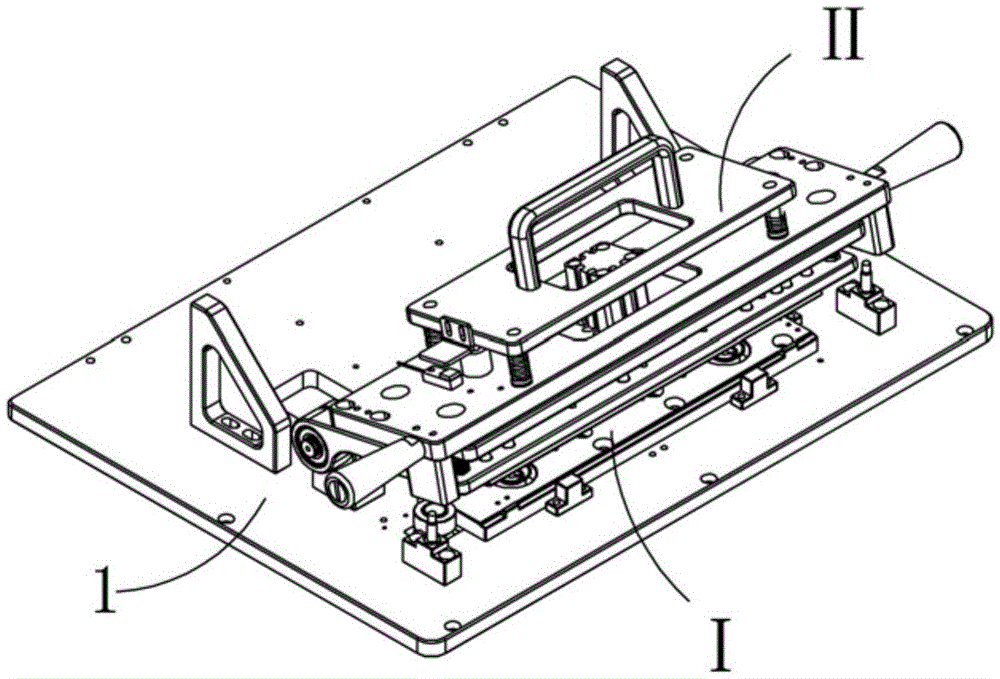

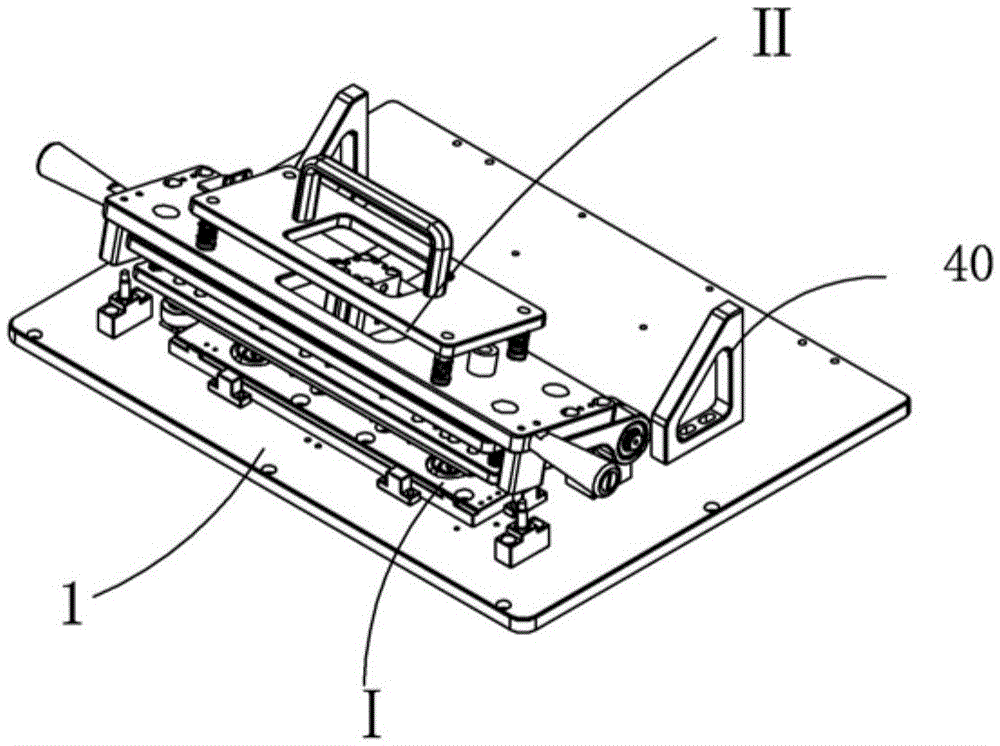

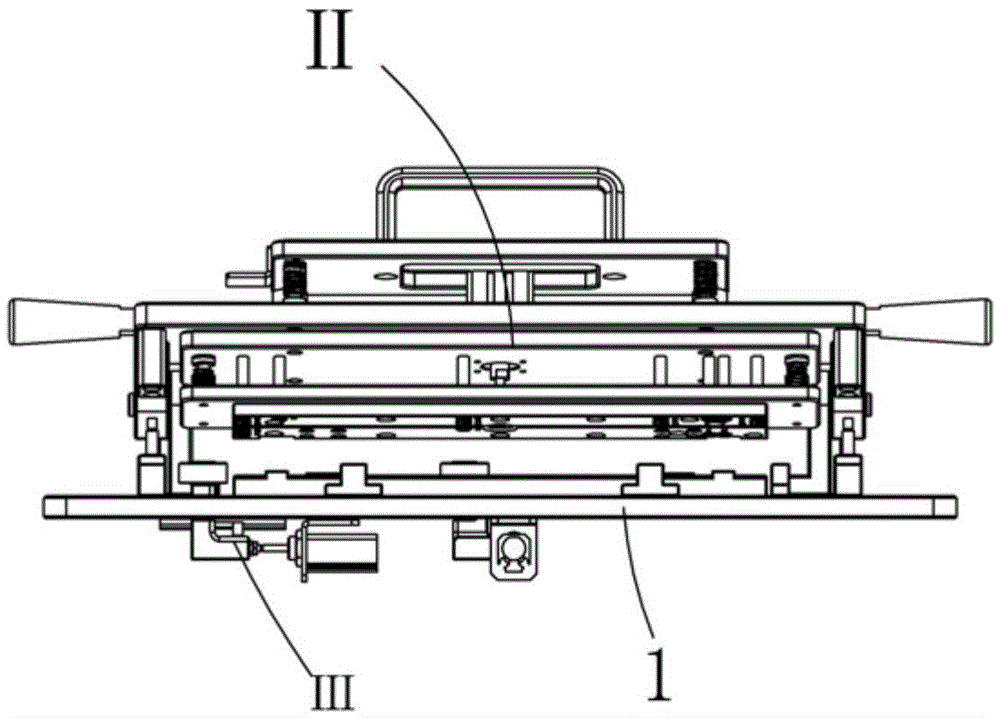

[0033] Examples, see attached Figure 1-13 , a new type of magnet assembly and pressing fixture, which includes a base plate 1, on which a carrier positioning mechanism I for carrying and positioning products is installed; the base plate is equipped with a rotary pressing mechanism for assembling product magnets onto products Ⅱ. The rotary pressing mechanism is located directly above the carrier positioning mechanism.

[0034] The carrier positioning mechanism includes a carrier 2, and a suction cup 3 is installed on the carrier. There are two suction cups, which are symmetrically installed on the left and right sides of the upper part of the carrier. Products are adsorbed on the sucker; the bottom plate is located on the right side of the carrier. A first positioning block 4 is installed on the side; a second positioning block 5 is installed on the bottom plate and on the front side of the carrier; a first positioning component III is installed on the bottom plate and on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com