Rotary supporting structure

A technology of rotating support and supporting plate, which is applied in the direction of measuring devices, surveying and navigation, instruments, etc., can solve the problems that the performance of the rotating support structure needs to be improved, and achieve the effect of simple structure, stable working state and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

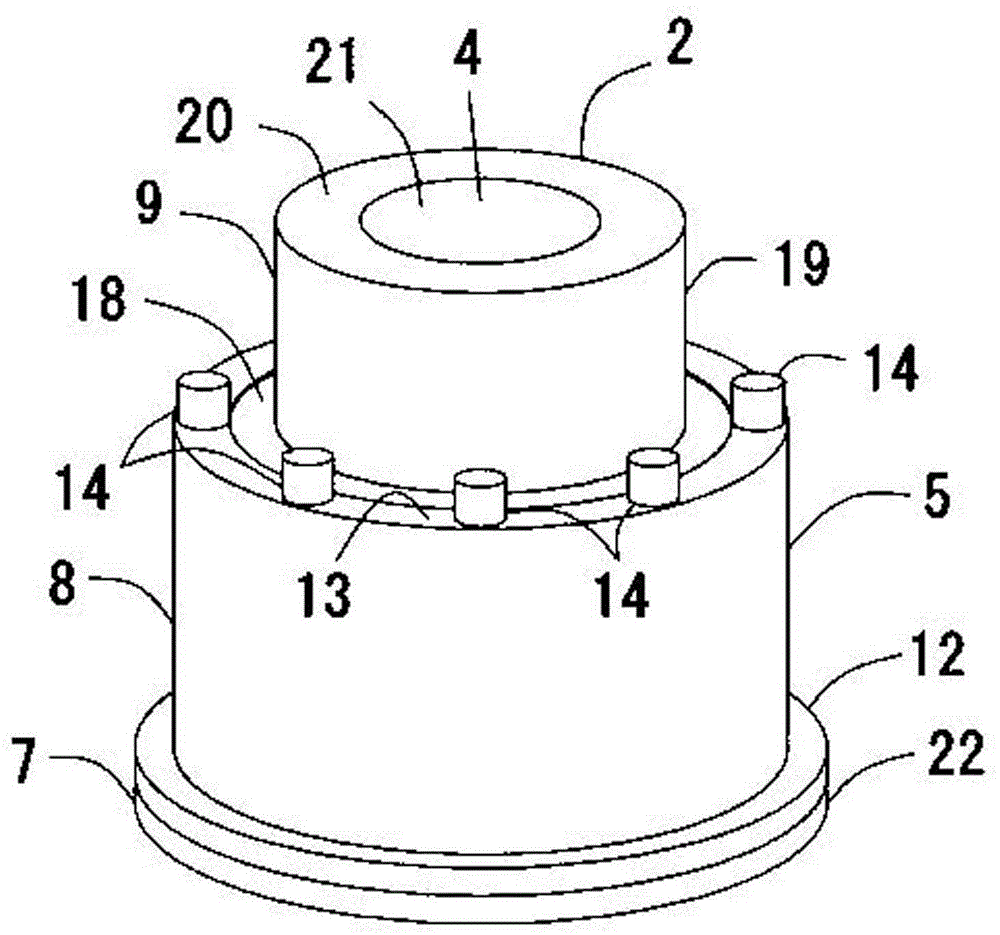

[0018] A rotating support structure of the present invention, including a rotating body 2, a cavity 4, a seat body 5, a base 7, an outer sleeve 8, a rotating sleeve 9, a support plate 12, a mounting seat 13, a sensor 14, an inner sleeve 18, and a side wall 19 . The supporting surface 20, the inner wall 21, and the chassis 22 are characterized in that: the base 7 is provided with a seat body 5, the seat body 5 is provided with a swivel body 2, and several upward sensors 14 are also provided on the seat body 5.

[0019] As a preferred solution of the present invention, the base 7 is composed of a chassis 22 below and a support plate 12 above; the seat body 5 is arranged on the support plate 12 .

[0020] As a second preferred solution, the upper end of the upper cylinder is provided with a flange. The seat body 5 is composed of an outer casing 8 and an inner casing 18; the outer casing 8 is placed on the mounting seat 13, and the mounting seat 13 is provided with a sensor 14 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com