A continuous multi-purpose stamping machine

A stamping machine, multi-purpose technology, applied in printing, stamping and other directions, can solve the problems of single, single stamping action, can not meet the needs of users, and achieve the effect of wide range of uses and high-efficiency work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

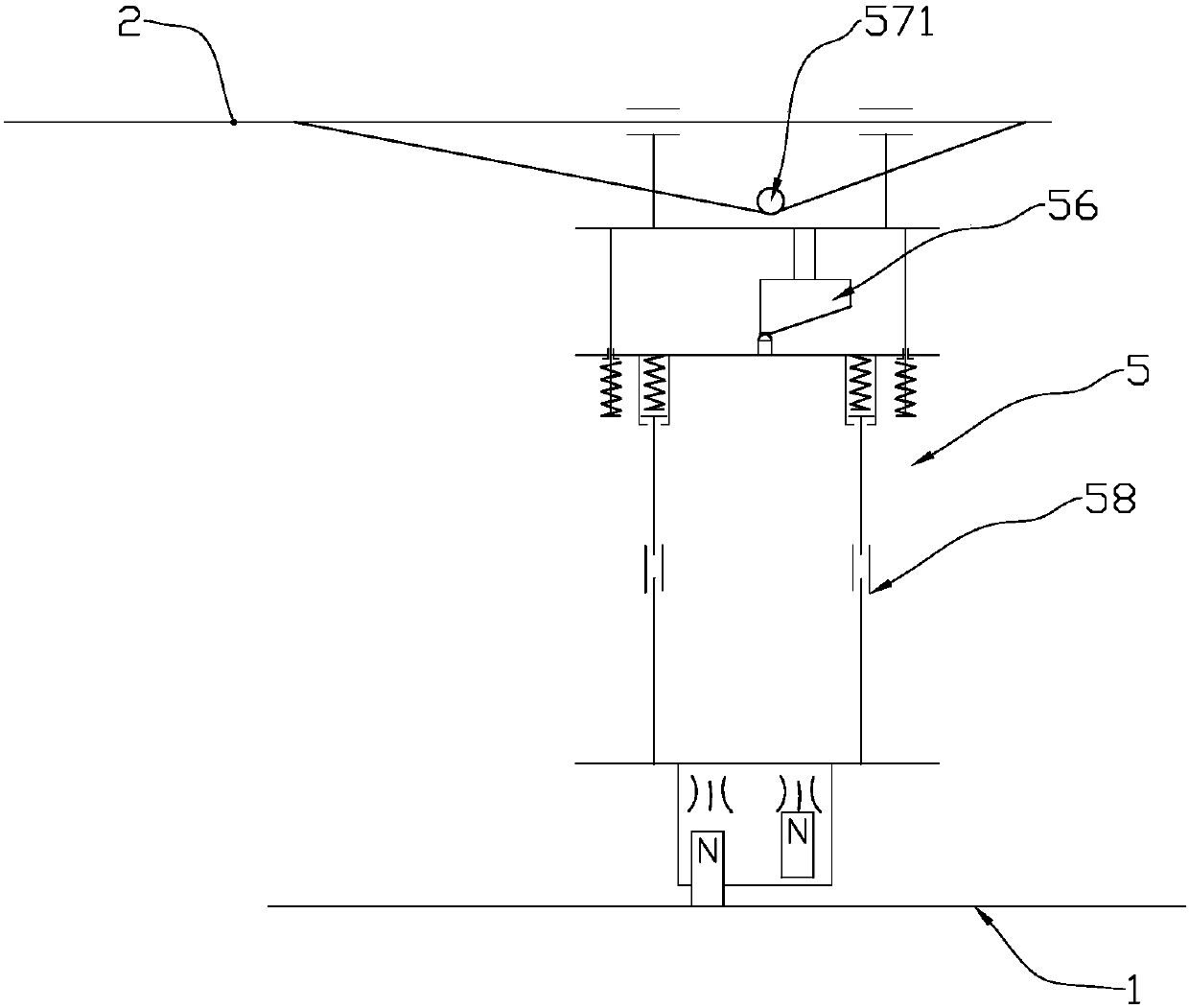

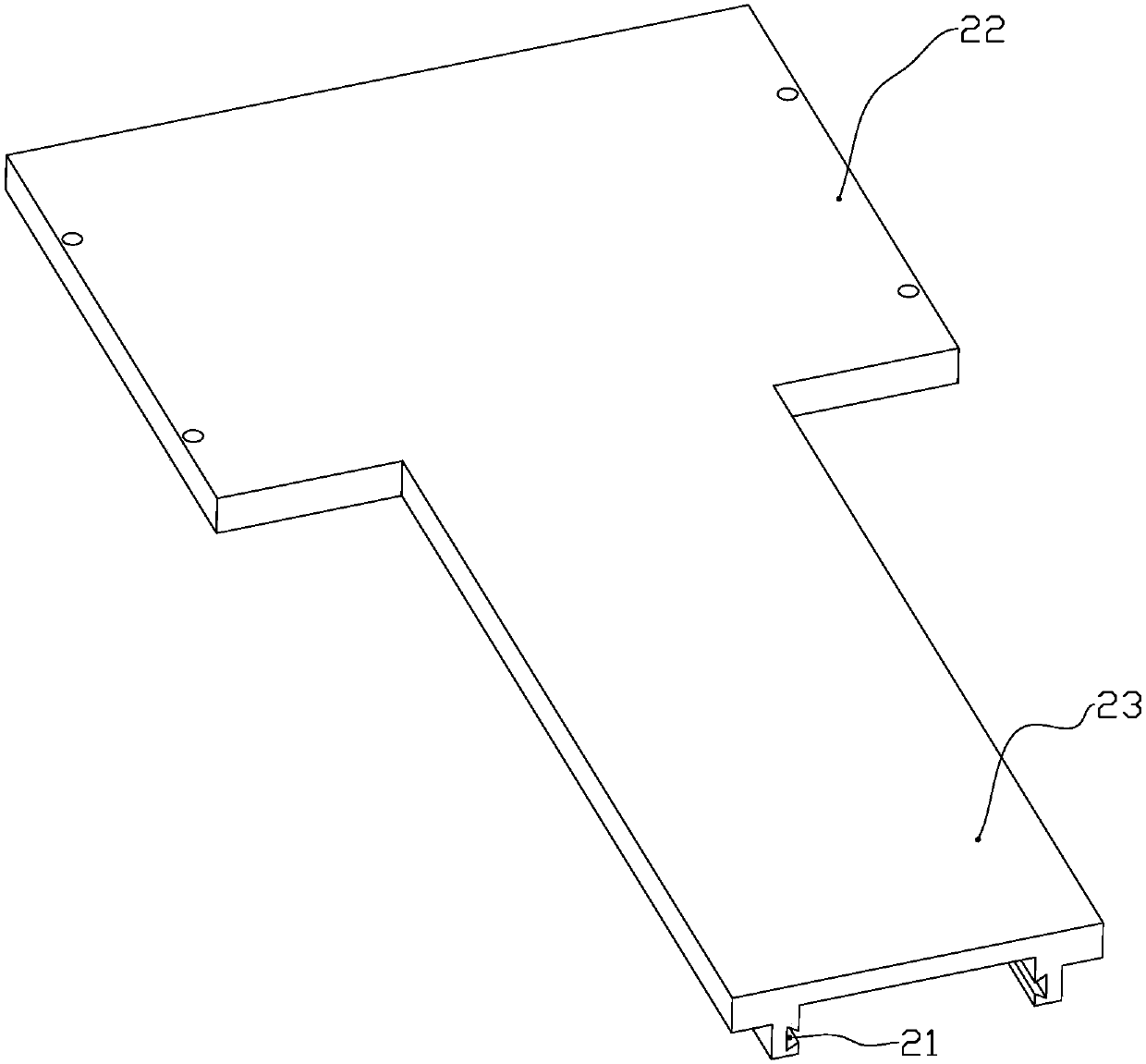

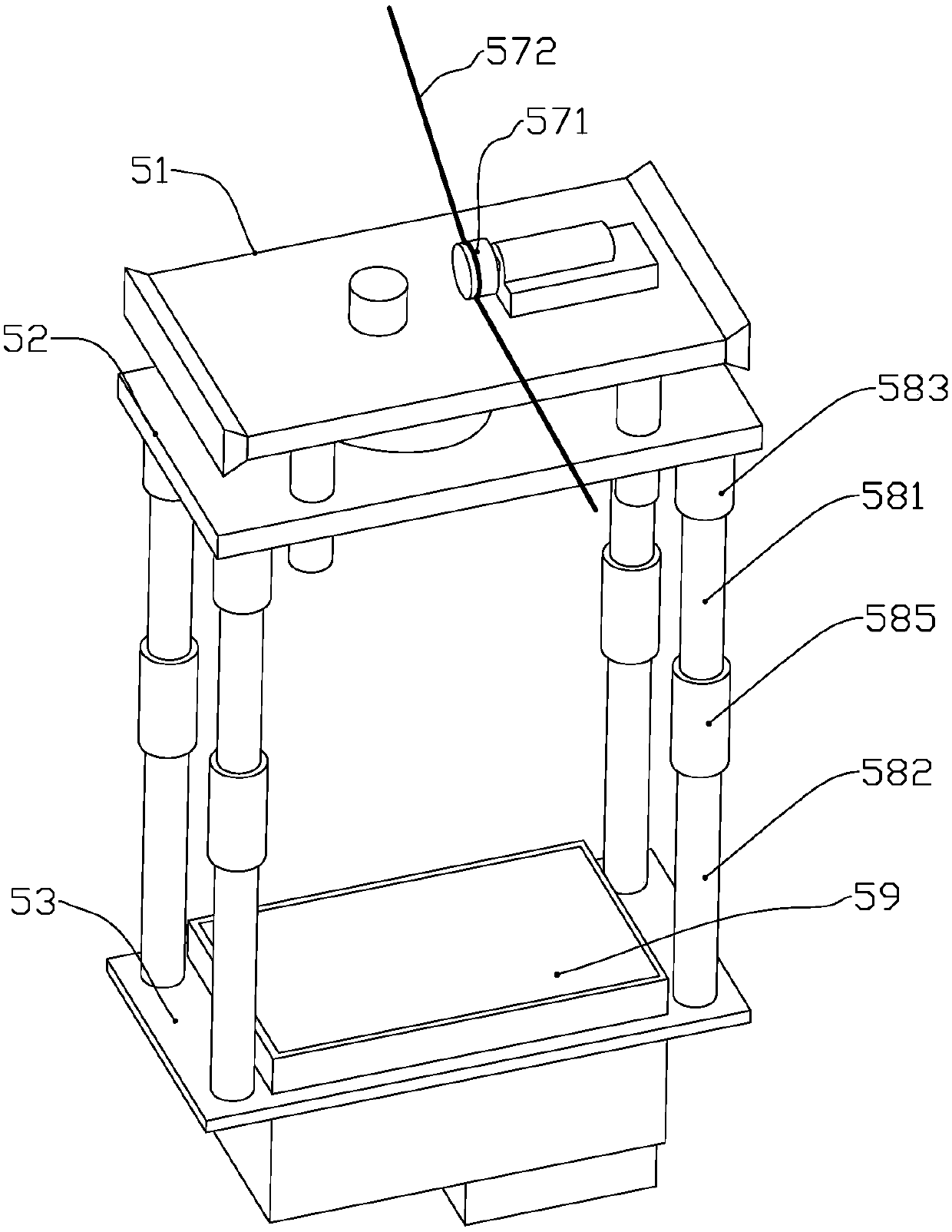

[0031] Such as Figure 1 to Figure 11 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0032] What is developed is a continuous multi-purpose stamping machine. Its basic principle is to use the longitudinal motor to move longitudinally, which can meet the stamping needs of different longitudinal positions, and use the principle of electromagnetic attraction to release different stamps. Stamping is carried out in a targeted manner to achieve accurate stamping. In addition, in the process of stamping, it has a buffering effect, which can achieve uniform force effect and good stamping quality. At the same time, the seal is an atomic seal, which can be stamped repeatedly with one addition of ink, and the seal is clear, which has the characteristics of clear seal marks.

[0033] Based on the above description, the stamping machine provided by the present invention consists of the following parts:

[0034] The frame part, which in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com