Sectional type bow mast

A segmented, bow-mast technology, applied to masts, ship parts, ships, etc., can solve the problems of increased self-weight and wind-receiving area, and increased bow-mast height, so as to improve economy and reliability, and reduce its own weight , Improve the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and that the descriptions and illustrations therein are illustrative in nature and not intended to limit the present invention. invention.

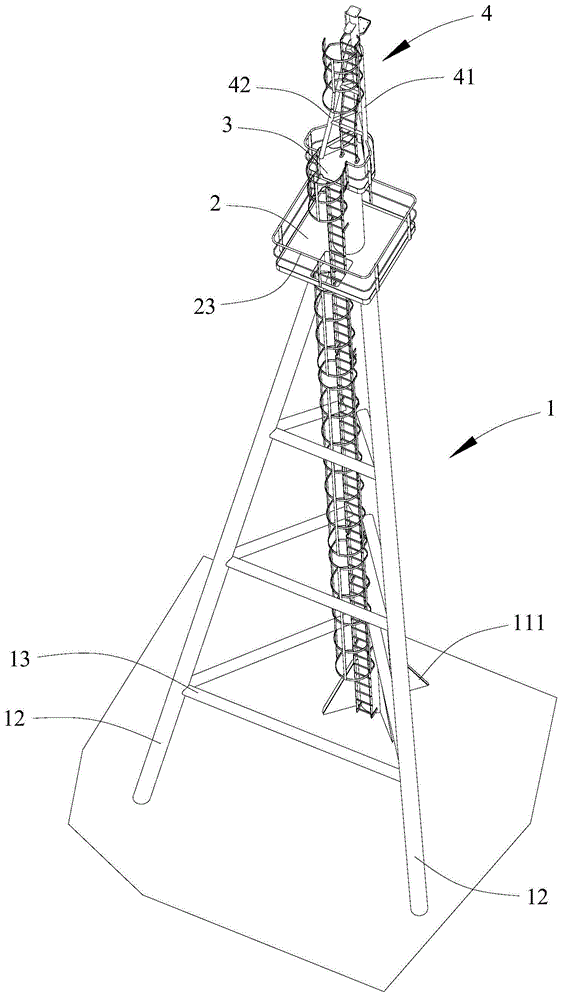

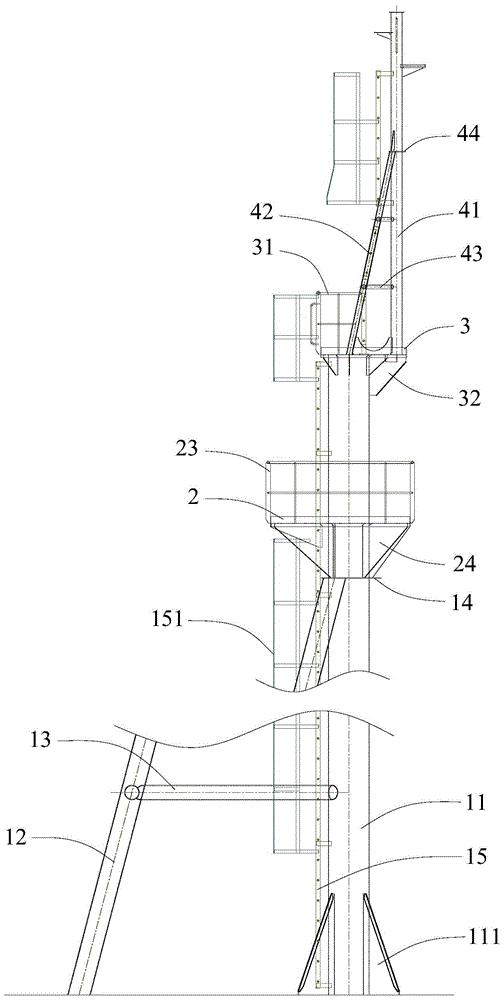

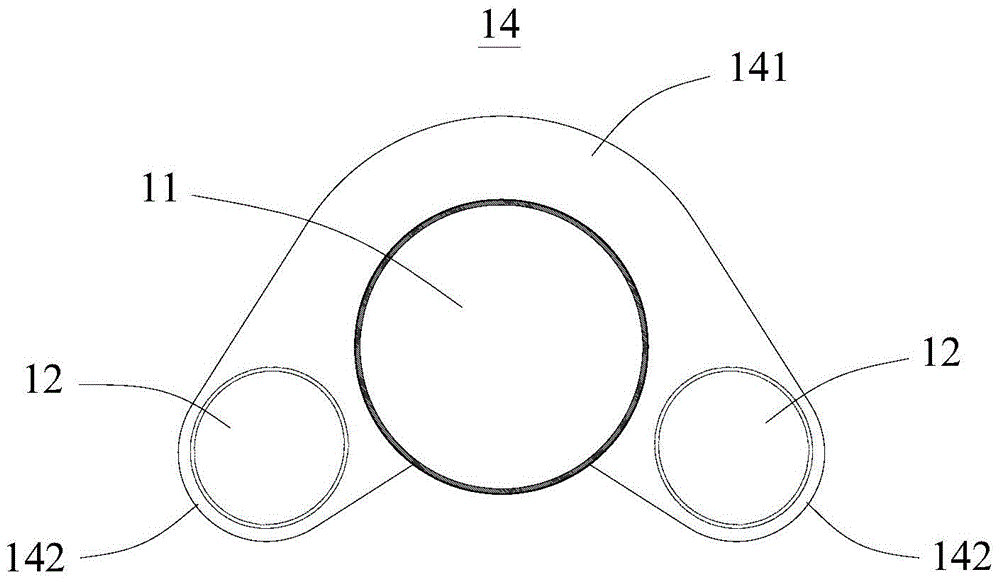

[0028] Such as figure 1 As shown, the present invention proposes a segmented bow-mast which can be mounted on the deck 5 of a vessel such as a large container ship. Due to the increasing scale of construction of large container ships, the height of the bow and mast of the ship is also increasing. In order to meet the requirement of raising the height of the bow-mast and optimize the dead weight and wind-receiving area of the bow-mast, the present invention proposes a two-stage bow-mast. Wherein, the segmented bow mast mainly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com