Integral molded packaging box, molding die and molding method for molding the packaging box

A technology for forming molds and packaging boxes, which is applied in the field of packaging, can solve the problems of increased processing procedures and manufacturing costs, cumbersome packaging box forming process, and insufficient support, and achieves the effects of convenient and fast molding, simple and practical structure, and strengthened support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

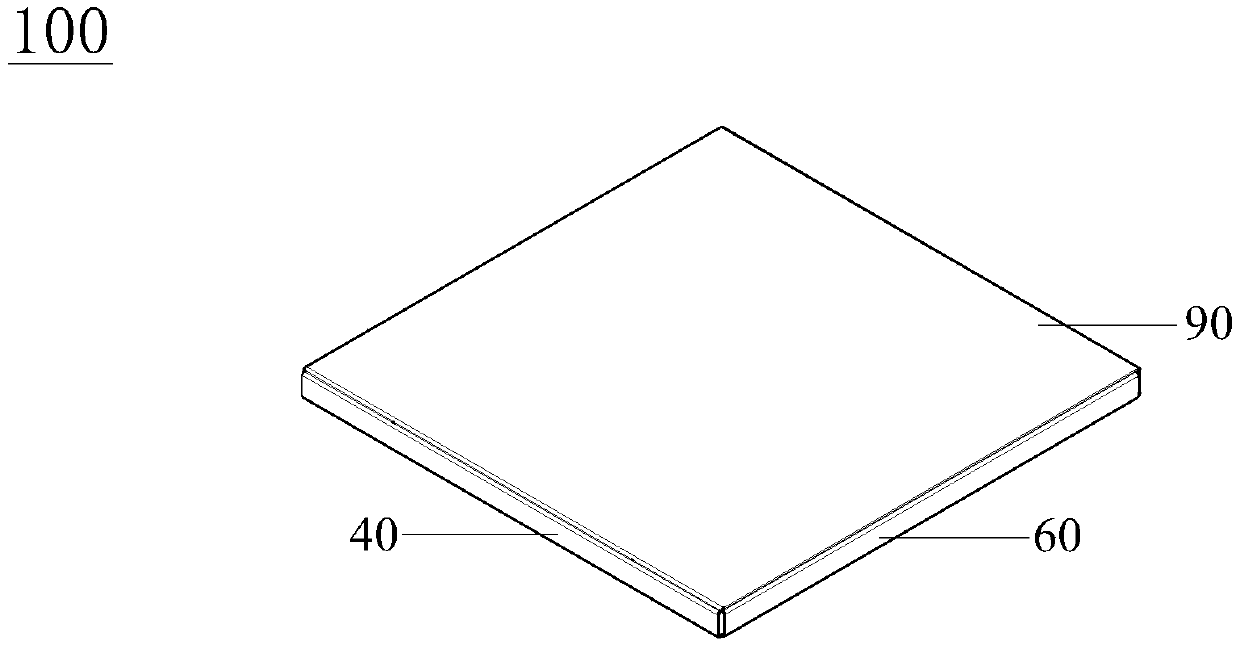

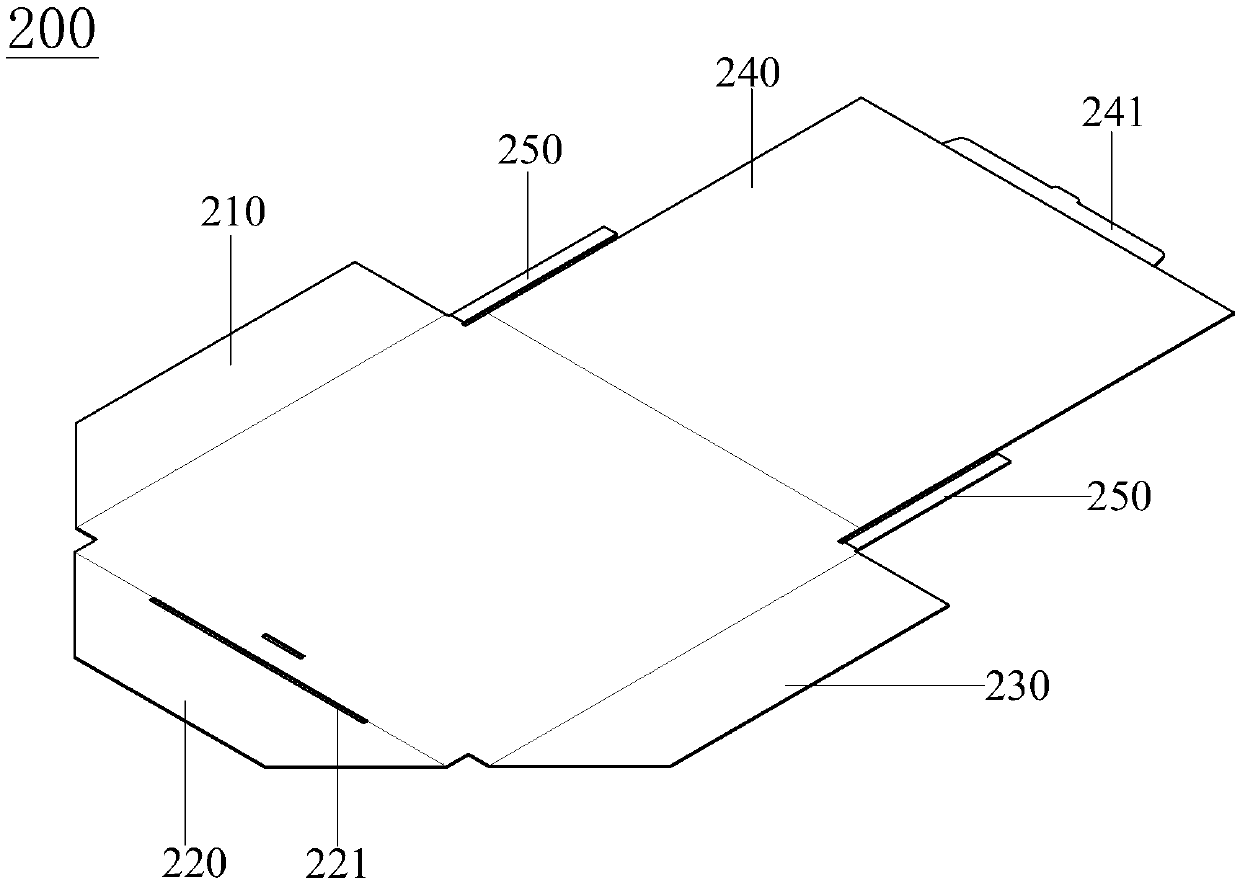

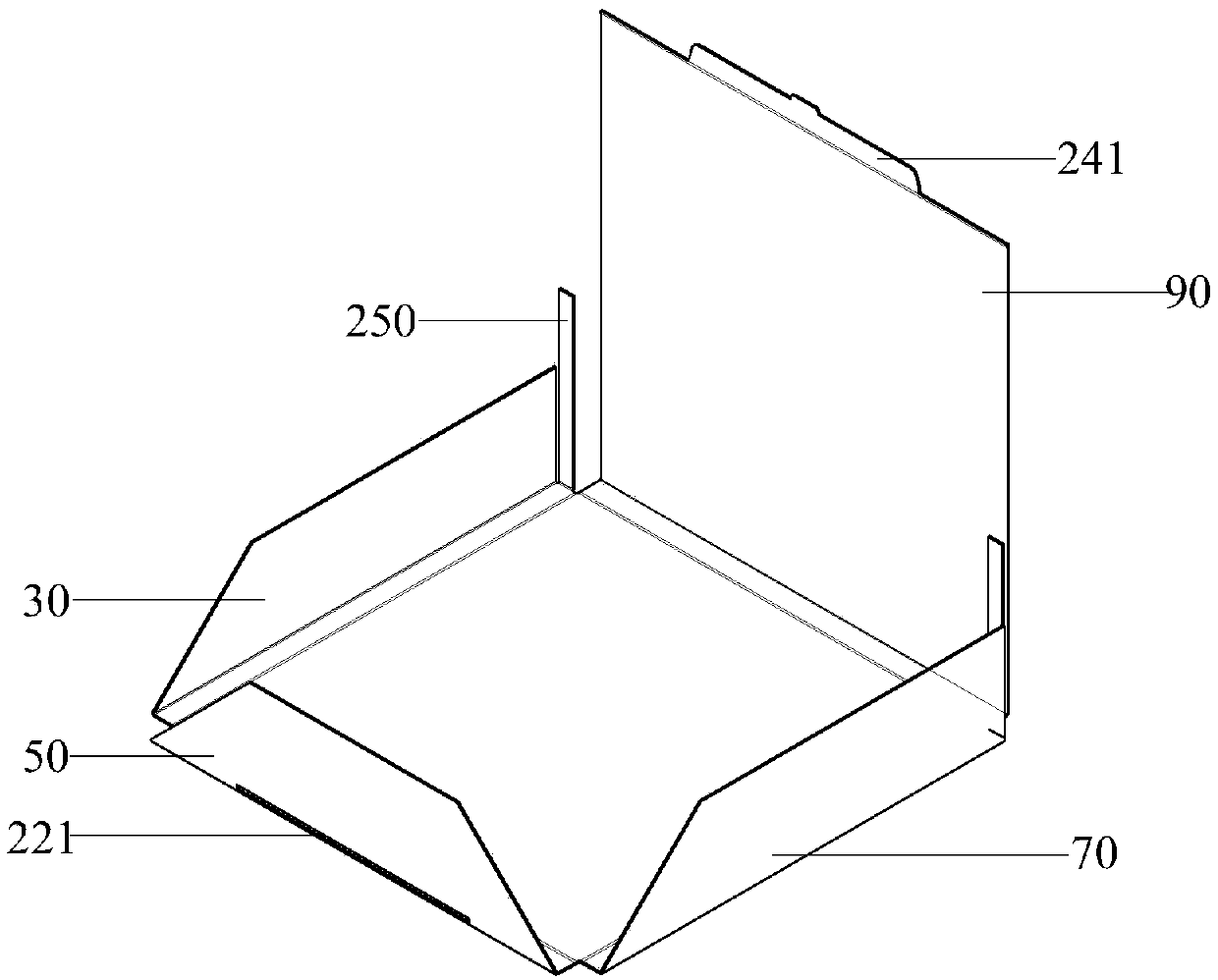

[0033] see Figure 1 to Figure 8 , the present invention discloses an integrally formed packing box 100, the packing box 100 includes a bottom plate 10, a left side plate 20, a left cover plate 30, a front side plate 40, a front cover plate 50, a right side plate 60, and a right cover plate 70 , the rear side panel 80 and the top cover 90, the packaging box 100 is formed by a paper sheet 200 without creases by secondary bending and buckling of a molding die, and the paper sheet 200 includes a first flap 210 connected together , the second flap 220, the third flap 230, the fourth flap 240 and the fifth flap 250, the fifth flap 250 is located between the fourth flap 240 and the first flap 210 and / or the fourth flap Between the sheet 240 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com