Milk powder can with measuring function

A technology for milk powder cans and milk powder, which is applied in the distribution of powdered materials, etc., can solve the problems of milk powder pollution, entrained milk powder, unbalanced nutrition of infants and young children, etc., and achieves the effect of shortening the brewing time and simplifying the milk brewing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

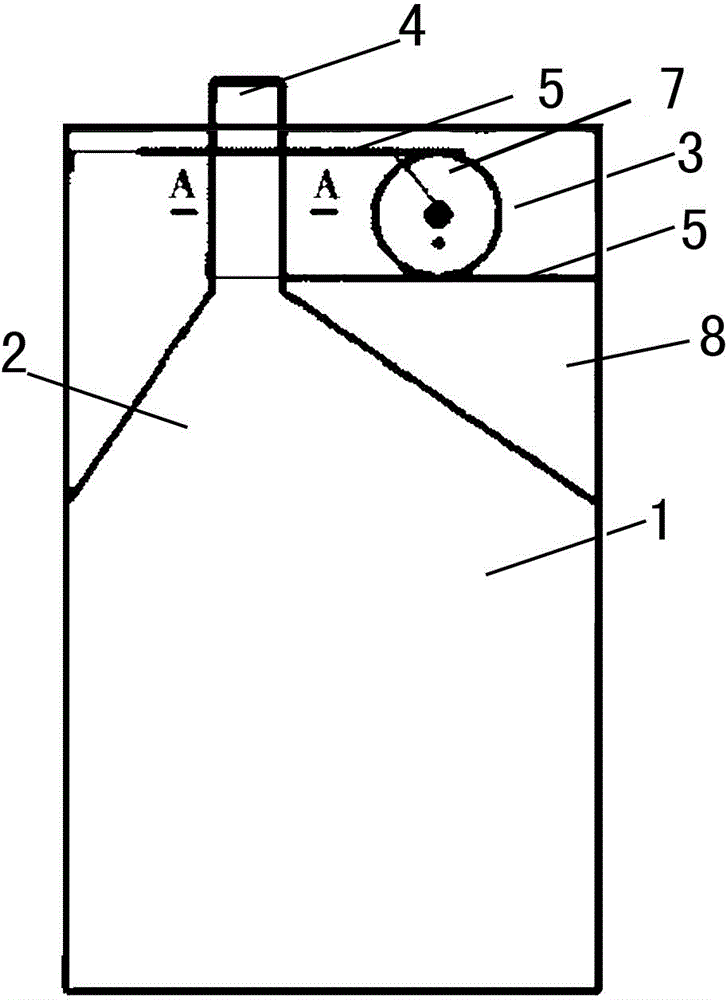

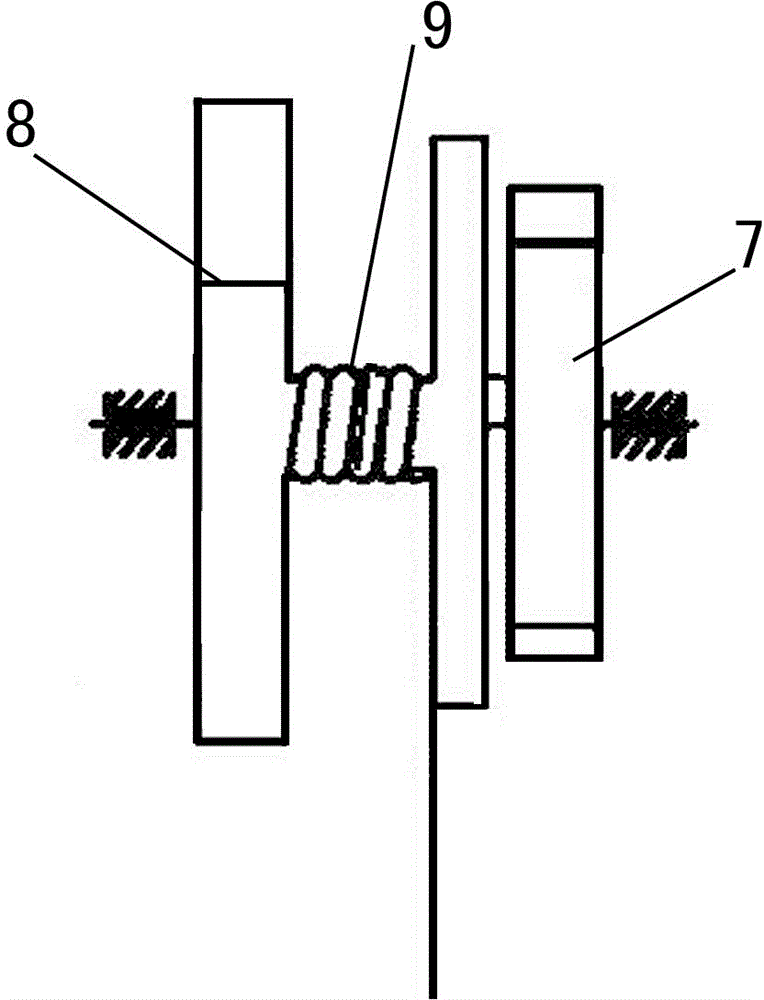

[0013] A meterable milk powder tank, comprising an upper tank body 2, a lower tank body 1, a metering chamber 8 and a milk powder outlet 3, characterized in that: the upper part of the lower tank body 1 is provided with a thread to connect with the upper tank body 2; The body 2 is provided with an opening 4, and the opening 4 is connected with the upper metering chamber 8; a switch piece 5 is arranged between the opening 4 and the milk powder outlet 3, and a gear shaft 7 is arranged between the switch piece 5; The right end of switch piece 5 is a rack structure.

[0014] Specifically, the present invention consists of a lower tank body 1, an upper tank body 2 and a metering chamber 8 in the upper tank body. Milk powder is stored in the tank body 1 at the lower end, and an opening 4 is arranged at the upper end of the tank body, and the opening 4 is directly connected with the metering chamber 8 at the upper end. Two switch pieces 5 are arranged between the opening 4 of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com