Automatic container wharf loading and unloading system and method for yard

A loading and unloading system and container technology, which is applied in the loading and unloading field of port container terminals, can solve the problems of long transportation distance of horizontal transportation equipment and the decline of road service level in the port, so as to improve loading and unloading efficiency and energy saving level, improve road service level, and container capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

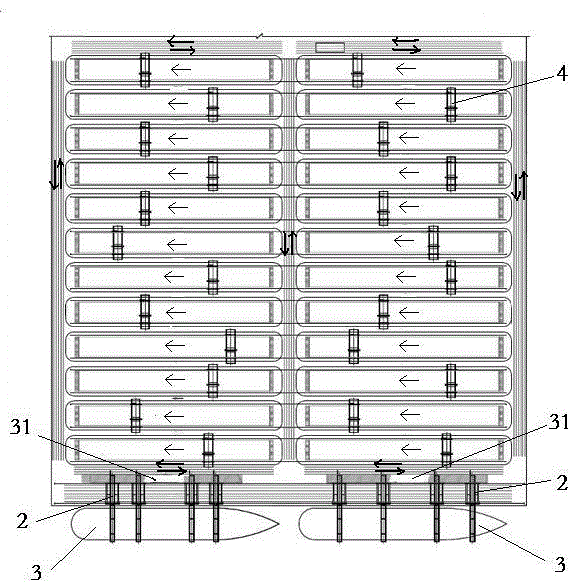

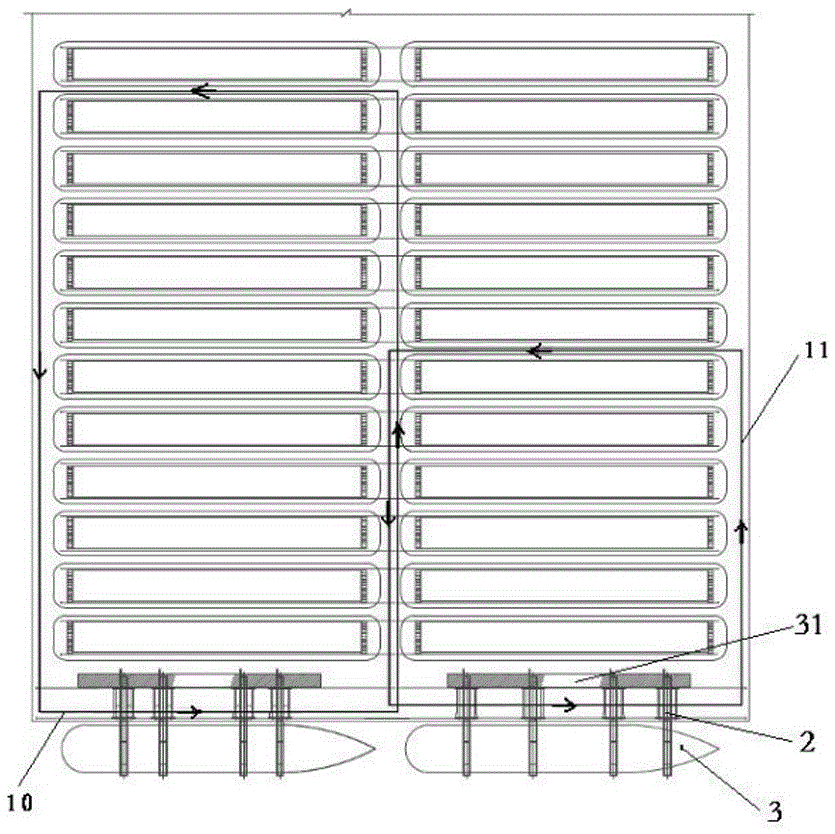

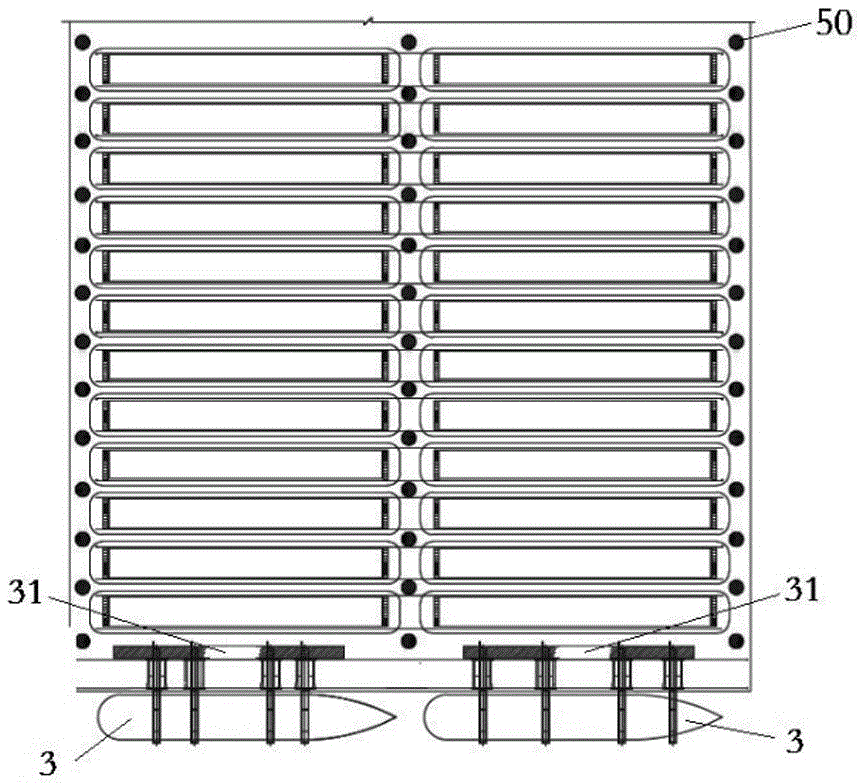

[0032] A yard automated container terminal loading and unloading system, such as Figure 4 As shown, it includes a quay crane 2, a collection truck 1, and a single cantilever rail crane (ARMG) 4 with automatic control; the quay crane 2 is used for vertical and horizontal transportation of containers from the container ship 3 to the shore operation area. The quay crane 2 is arranged at the front of the berth, and its track is parallel to the direction of the berth shoreline; the hatch cover 5 of the container ship is unloaded from the deck of the container ship 3 by the quay crane 2 to the hatch cover stacking area 31 in the track of the quay crane 2 . The container truck loading and unloading lanes for loading and unloading operations are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com