High-performance composite twelve-strand double-braided cable and production method thereof

A high-performance, cable technology, applied in the rope field, can solve the problems of substandard production requirements, substandard materials, incompatibility of fire resistance and strength of cables, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

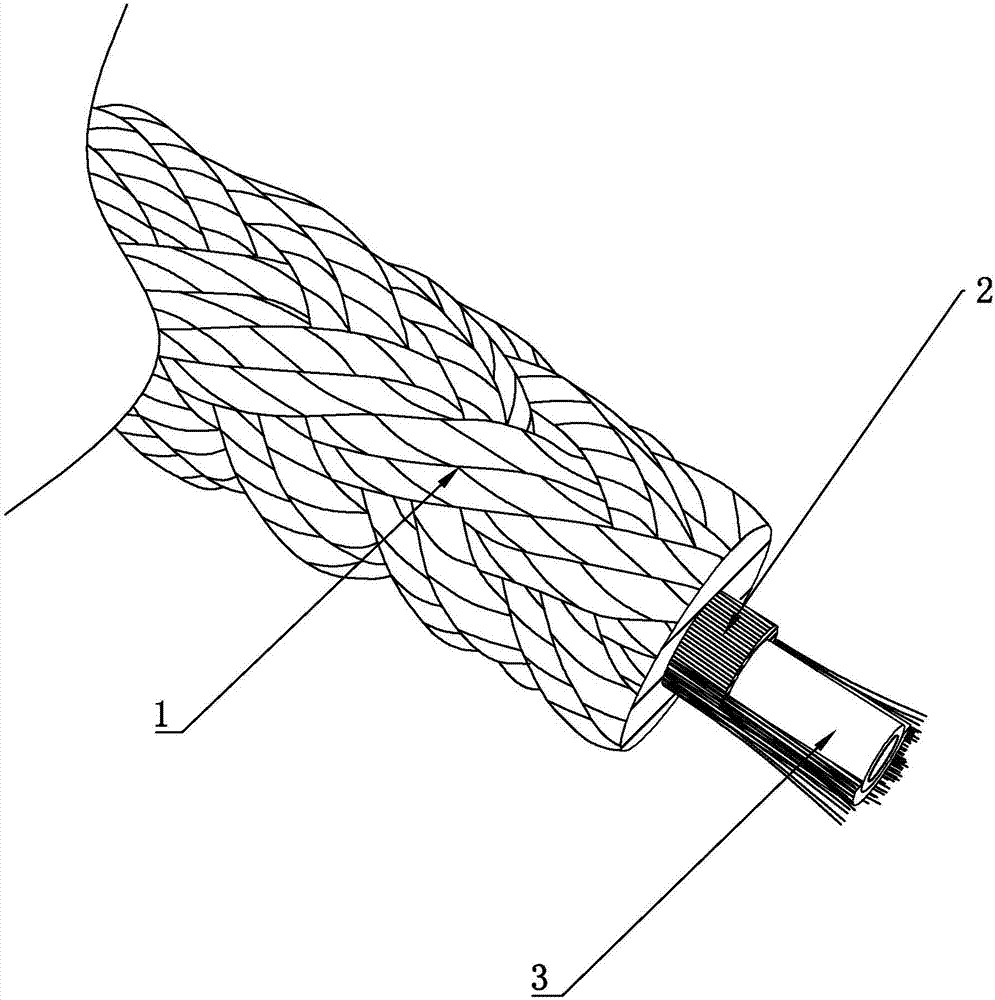

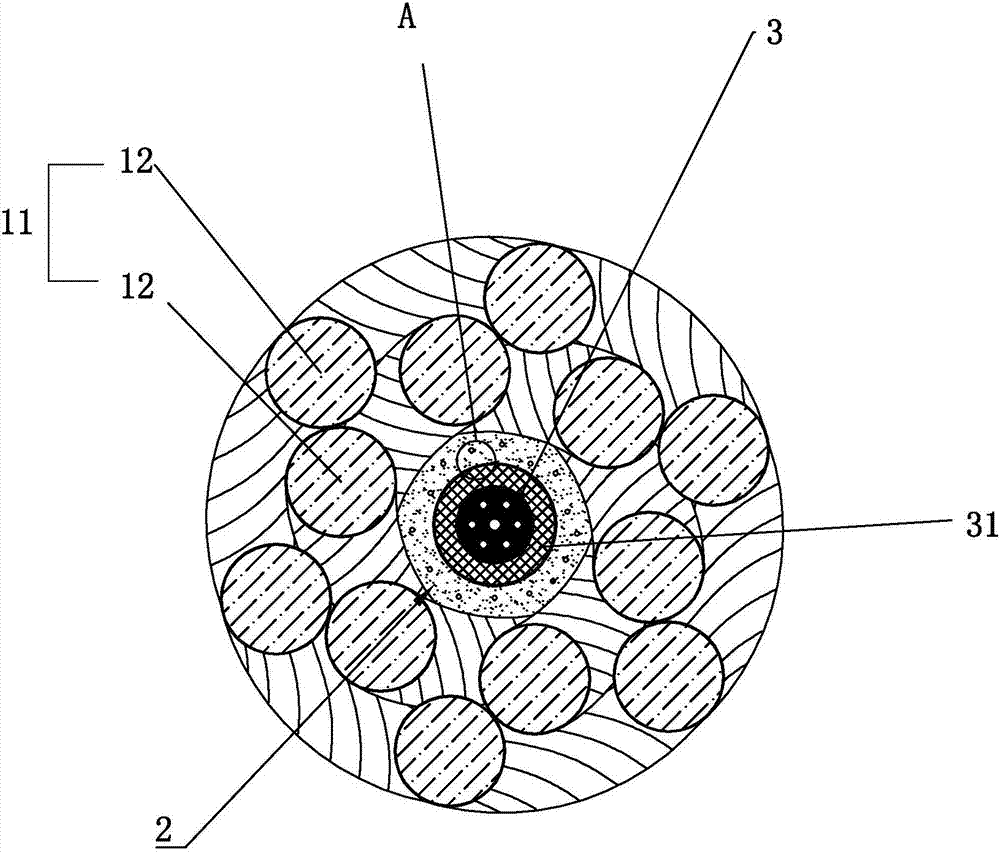

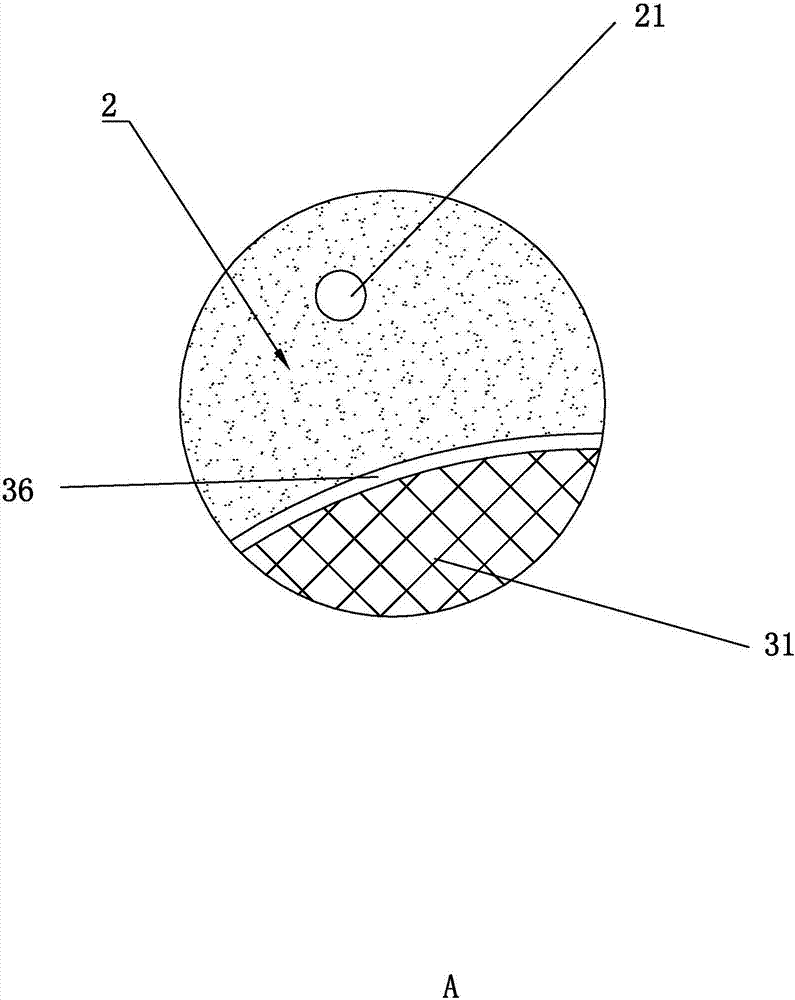

[0038] Embodiment one: if Figure 1 to Figure 6 As shown, a high-performance combined twelve-strand double-braided cable includes a core wire 3 and a cable body 1 sleeved on the core wire 3, and the core wire 3 and the cable body 1 are also provided with a buffer layer 2; the cable The main body 1 includes a plurality of main strands 11 intertwined with each other; the main strand 11 consists of two parallel auxiliary strands 12 twisted from basalt fibers; the auxiliary strands 12 in the main strands are parallel to each other. Basalt fiber only has the characteristics of high strength, high temperature resistance, good durability, corrosion resistance (acid and alkali resistance), no water absorption, good dielectric properties, radiation protection, certain comprehensive properties such as wave absorption and wave transmission, and moderate cost performance. Moreover, the tensile strength (single filament strength) of the basalt fiber is 3000~4800Mpa, so that it has good fir...

Embodiment 2

[0049] Embodiment two: if Figure 7 As shown, the difference from the first embodiment above is that the plurality of auxiliary wire cores 332 are parallel to each other and are wound on the main wire core 331 with the main wire core 331 as the helical axis. In this way, during production, the outer wall of the main wire core 331 is evenly covered with the ultra-high molecular weight polyethylene fiber 32 that constitutes the core wire 3, and then the auxiliary wire core 332 is spirally wound on its outer wall, and then covered on the auxiliary wire core 332. Ultra-high molecular weight polyethylene fiber 32, so that the embedding work of the metal wire 33 in the core wire 3 can be completed, so that it can be wrapped between the auxiliary wire core 332 and the main wire core 331 by winding the auxiliary wire core 332 The ultra-high molecular weight polyethylene fibers 32 are more compact, which contributes to the structural strength of the entire cable.

Embodiment 3

[0050] Embodiment three: as Figure 8 As shown, the difference from the first embodiment above is that the several secondary cores 332 interweave and are wound on the main core 331 with the main core 331 as the helical axis. And the winding way of this kind of metal wire 33, also be first on the outer wall of main wire core 331 evenly cover on the ultra-high molecular weight polyethylene fiber 32 that constitutes core wire 3, then in the secondary wire core 332 that will interweave and twine Sleeve on its outer wall, and then cover the ultra-high molecular weight polyethylene fiber 32 on the auxiliary wire core 332, so that the embedding work of the metal wire 33 in the core wire 3 can be completed, and it can also be wound through the auxiliary wire core 332 In this way, the ultra-high molecular weight polyethylene fiber 32 wrapped between the secondary core 332 and the main core 331 is more compact, which contributes to the structural strength of the entire cable. Moreover,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com