Mechanism for transporting mother plate in progressive die

A transmission mechanism and master mold technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unsuitable micro parts, insufficient rigidity, high processing accuracy requirements, etc., and achieve the effect of convenient installation and testing, and easy part production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

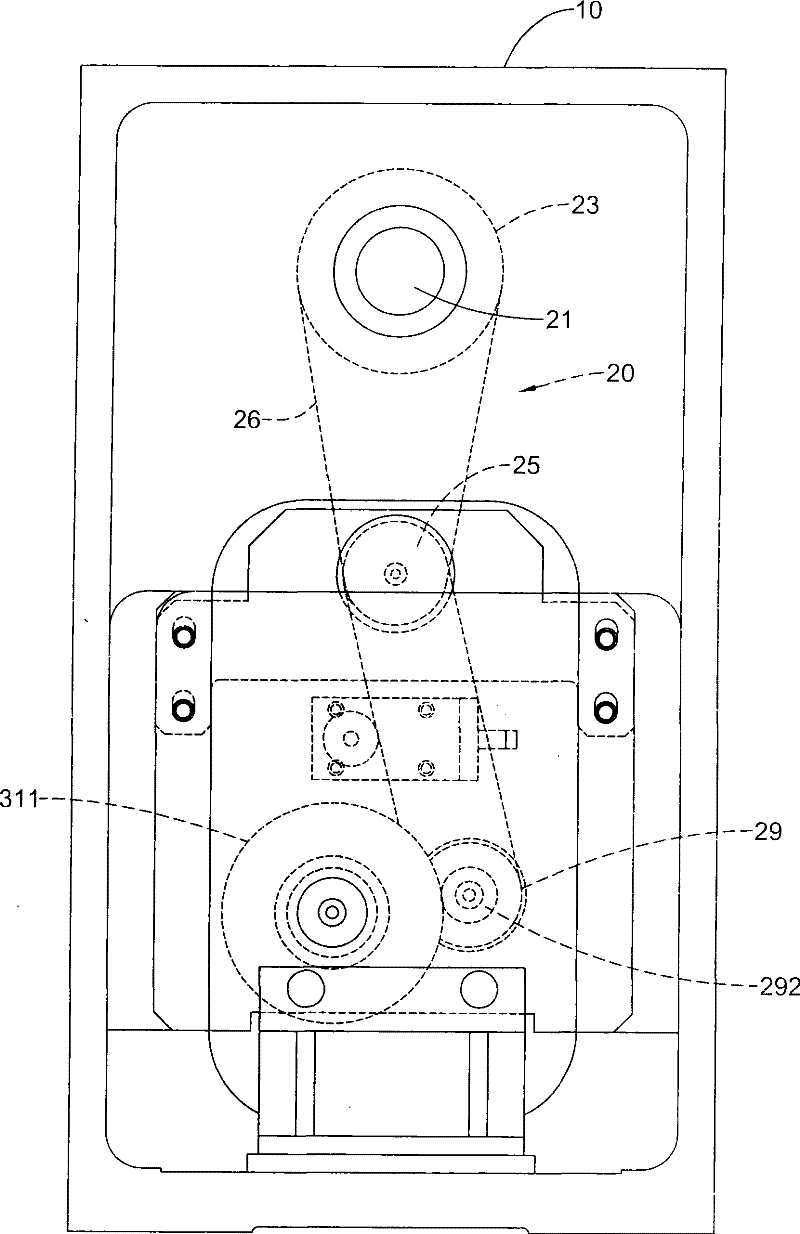

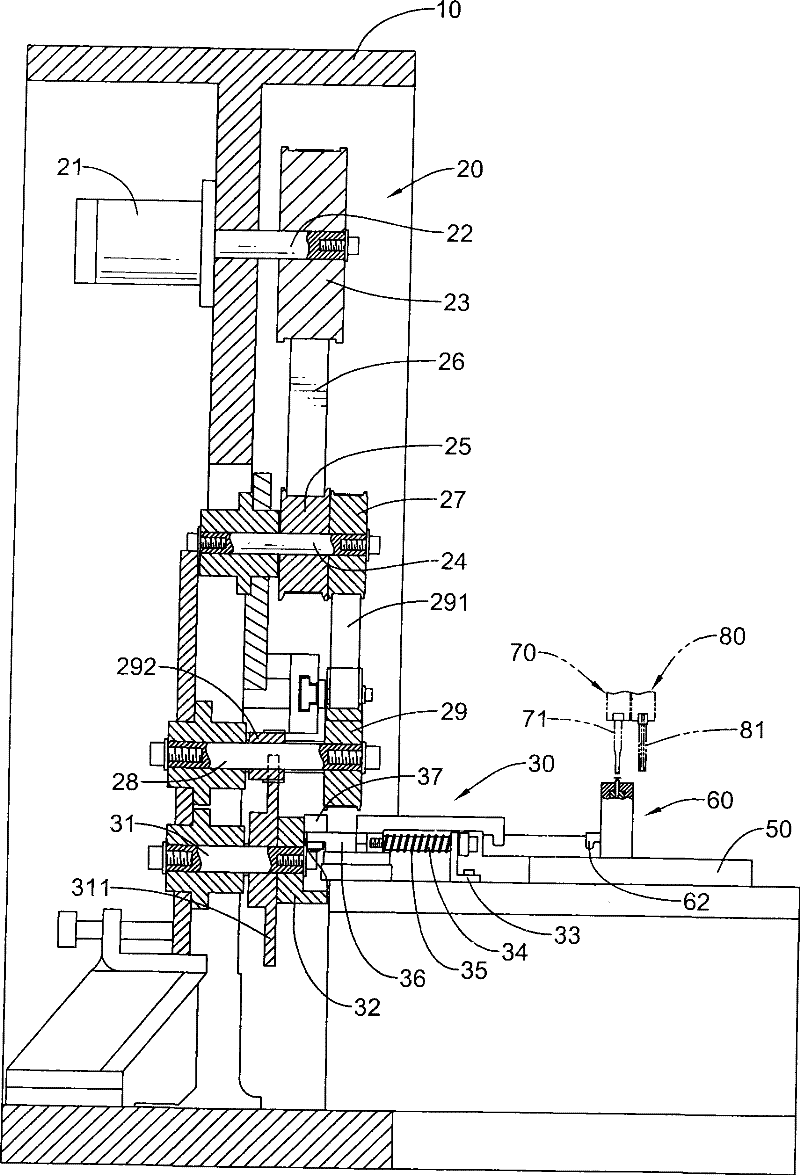

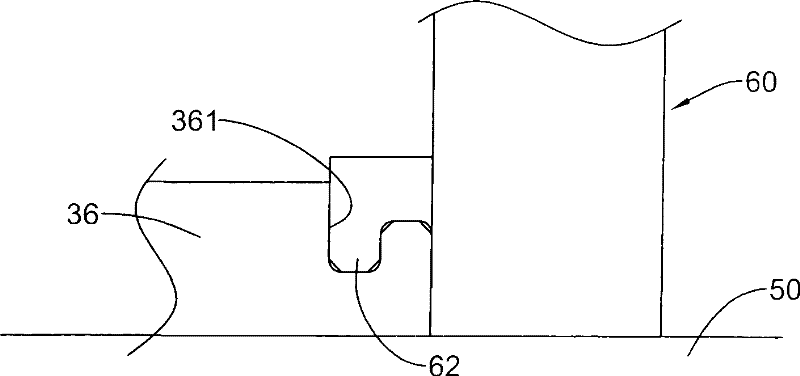

[0050] Cooperate with reference Figure 1 to Figure 3 As shown, the "continuous in-mold master mold transmission mechanism" of the present invention is to set a power device 20, a reciprocating device 30, a slide rail 50 and a master mold 60 in a machine table 10, and the master mold 60 is located at On the slide rail 50, the operation of the power unit 20 can drive the reciprocating device 30 and then drive the mother die 60 to move back and forth, and an array of punching die devices 70, 80 are arranged above the master die 60, and the front and rear movement of the master die 60 can be located at any die device 70 , 80 below for stamping work.

[0051] The power unit 20 has a motor 20, a first runner 23 is set on the output shaft 22 of the power of the motor 20, a first mandrel 24 is pivotally set on the machine table 10, and a first mandrel 24 is set on the first mandrel 24. Two runners 25 and the third runner 27, the first runner 23 and the second runner 25 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com