Giant prestressed tension string structure and construction method suitable for super-long-span coal yard closure

A prestressing and coal yard technology, applied in building construction, building material processing, construction, etc., can solve the problems of unstable compression components, reduce structural steel consumption, etc., achieve reduction in slenderness ratio, and save steel consumption Quantity, reasonable effect of acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

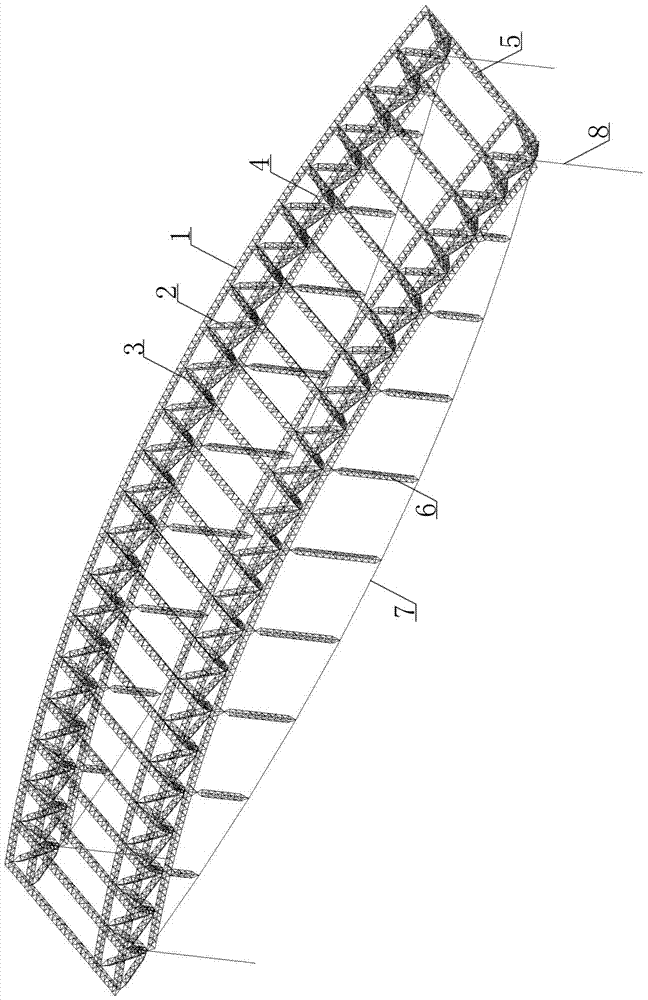

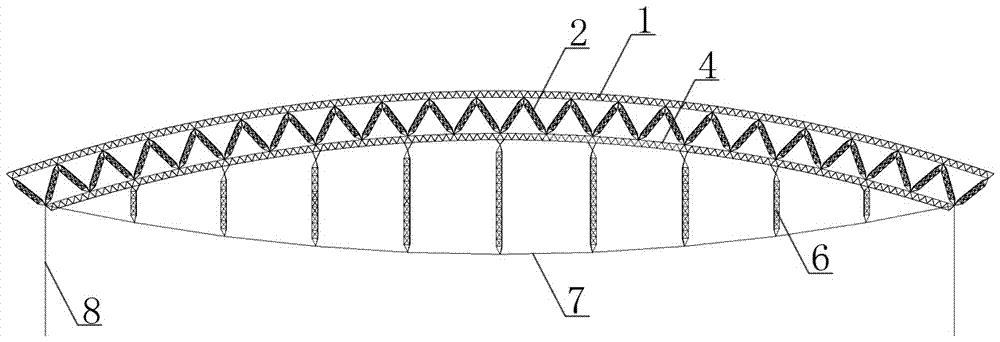

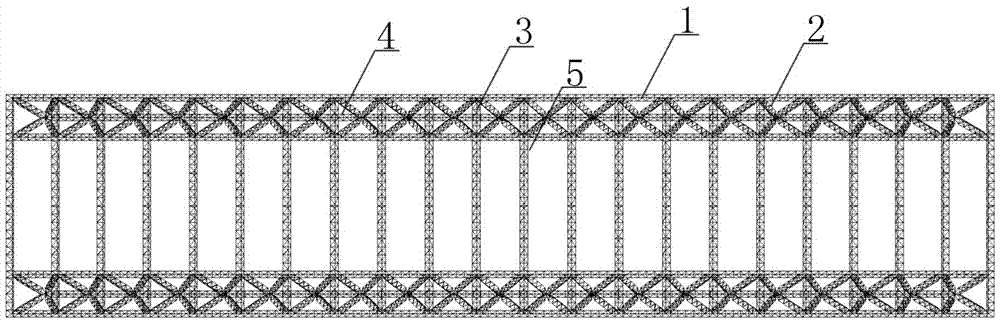

[0058] Examples see figure 1 , figure 2 , image 3 , Figure 4 As shown, this giant prestressed string structure suitable for the closure of super-long-span coal yards includes a group of prestressed stringed structure units arranged in parallel at intervals, and the distance between two adjacent prestressed stringed structure units is 40m. And connected by a connection structure, the connection structure is a group of connection trusses 5 arranged in parallel intervals between two adjacent prestressed string structure units; the span of each prestressed string structure unit is 300m, including space The trusses and the tension cables 7 connected under the space trusses are connected vertically between the space trusses and the tension cables 7 with a set of parallel spaced braces 6, and the braces 6 consist of 9 roads, The maximum length of the middle support truss 6 is 35m.

[0059] The space truss is a giant triangular space truss composed of a triangular space truss a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com