Fuel Flow Restriction Valves for Large Internal Combustion Engines

A large-scale internal combustion engine, fuel flow technology, applied in the direction of fuel injection device, charging system, mechanical equipment, etc., can solve problems such as valve seat sealing discount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

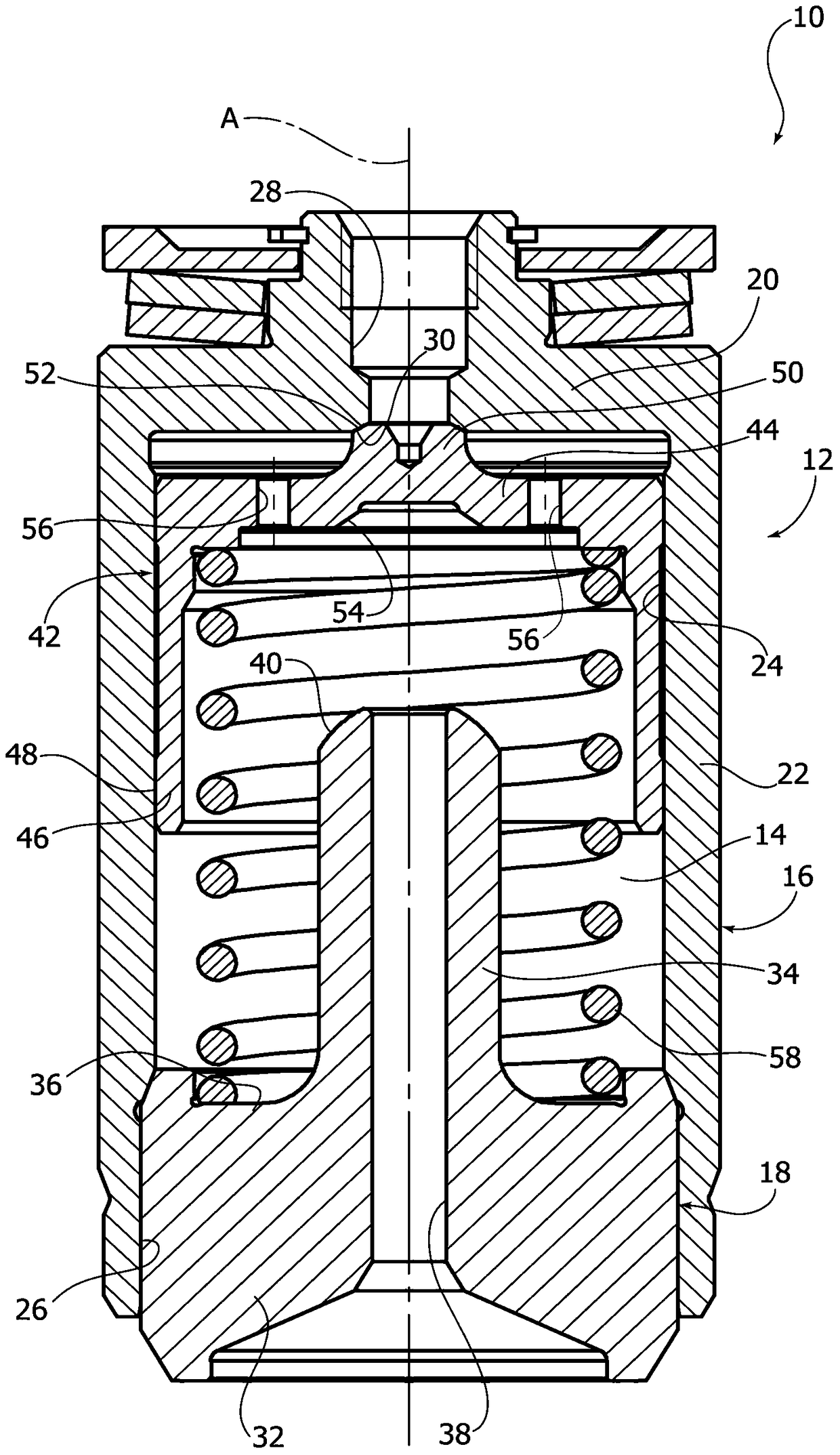

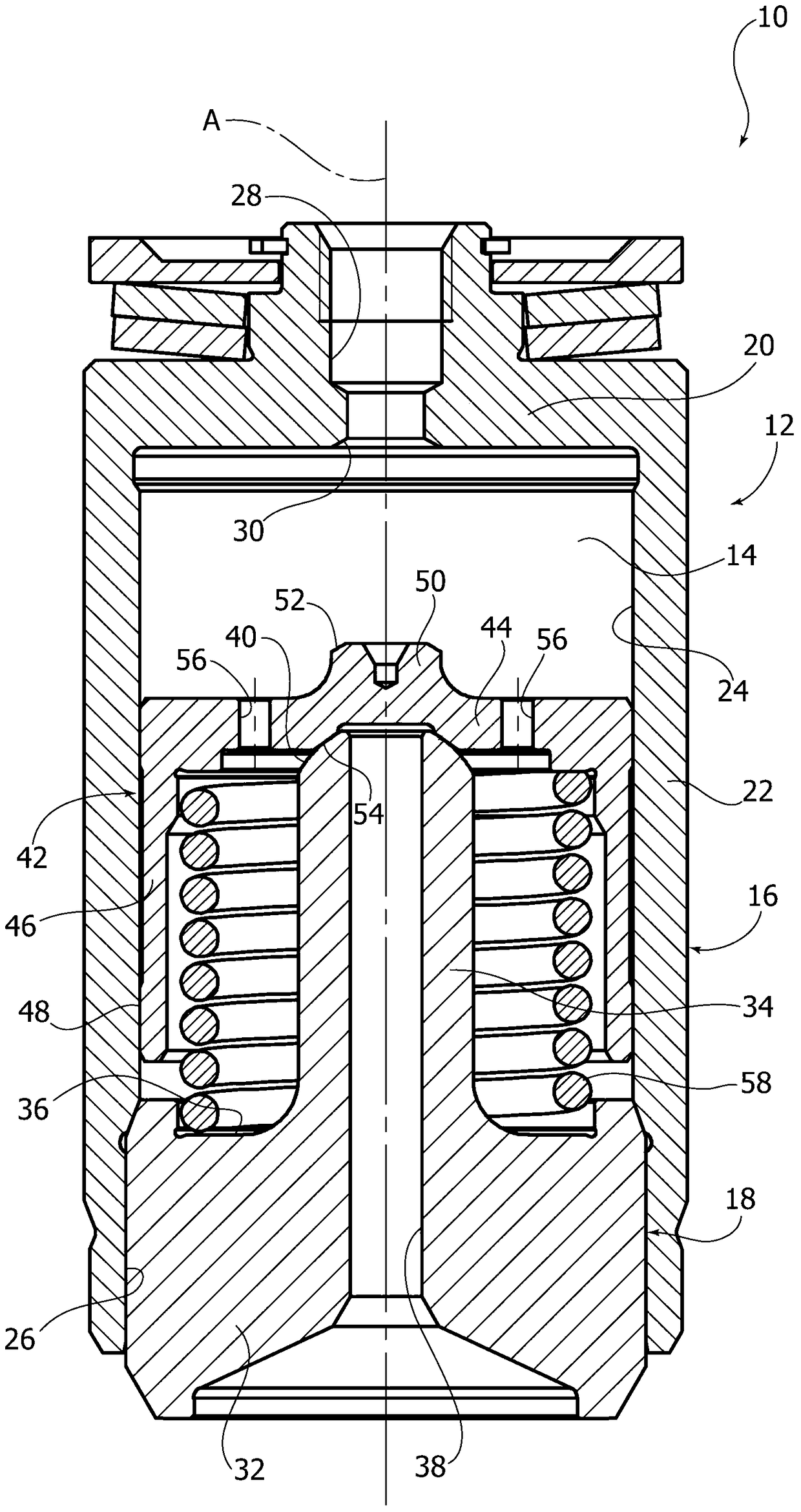

[0026] Referring to the drawings, reference numeral 10 denotes a fuel flow restriction valve intended to be used in a common rail injection system for a large internal combustion engine. The fuel flow restriction valve 10 includes a valve housing 12 defining a valve cavity 14 therein. The valve housing 12 is formed by a first housing 16 and a second housing 18 fixed to each other.

[0027] The first housing 16 includes a bottom wall 20 , and a side wall 22 extending from the bottom wall 20 and having a cylindrical inner surface 24 surrounding the valve cavity 14 . The side wall 22 of the first housing 16 has an open end portion 26 into which the second housing 18 is inserted and secured. An inlet passage 28 is formed on the bottom wall 20 of the first housing 16 , which communicates with the valve cavity 14 . The inboard end of the inlet passage 28 has an inlet valve seat 30 . In the example described, the inlet valve seat is formed by a conical concave surface.

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com