A kind of preparation method of lithium manganese phosphate lithium battery cathode material

A positive electrode material, lithium manganese phosphate technology, applied in the preparation of positive electrode material lithium manganese phosphate at low temperature and normal pressure, in the field of preparation of lithium battery positive electrode materials, can solve the difficulties in the design and manufacture of high temperature and high pressure reaction vessels, and the final product particle size Problems such as uneven distribution and low product specific capacity can achieve the effects of eliminating high temperature and high pressure environment, reducing reaction energy barriers, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

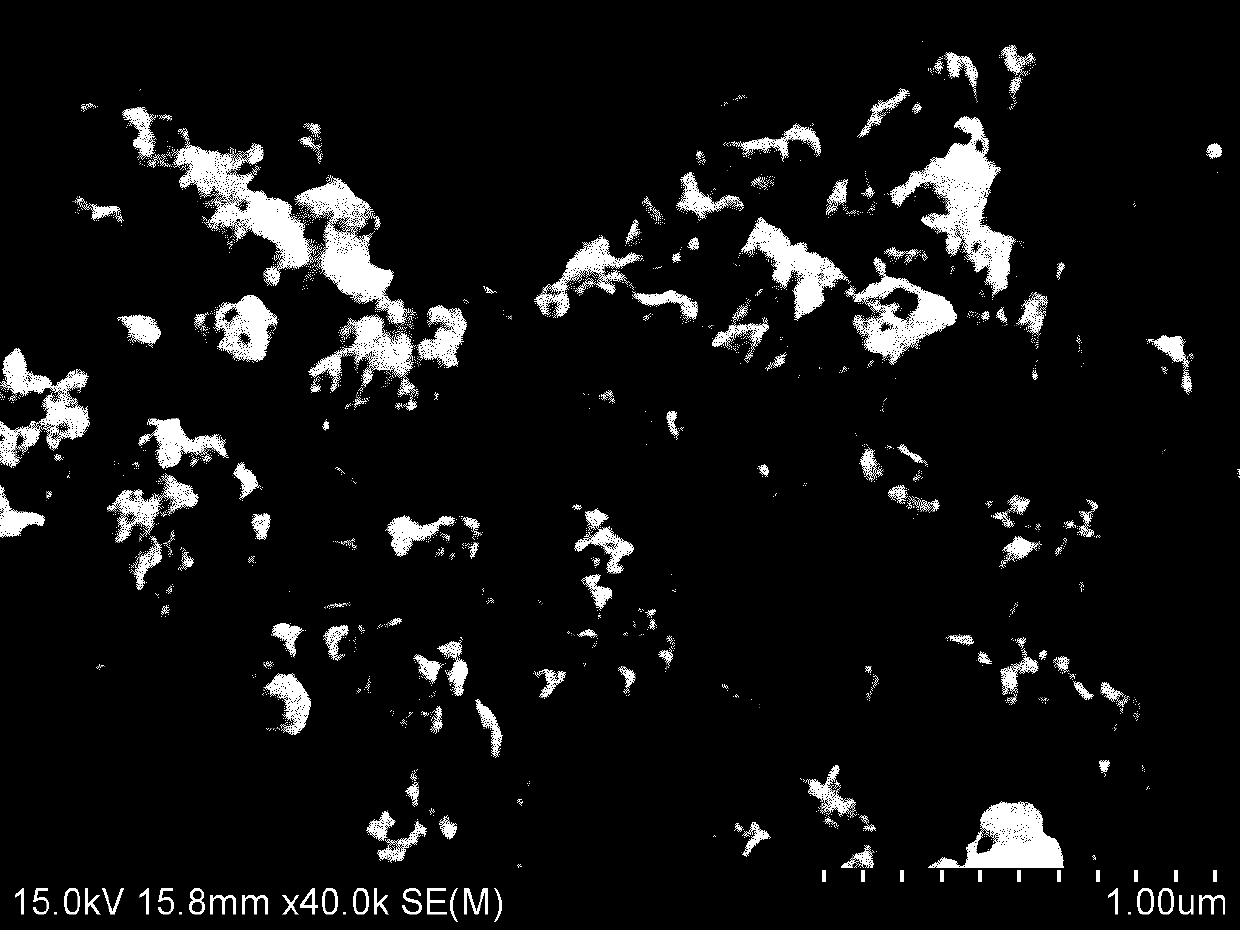

[0045] Embodiment 1: as figure 1 , figure 2 Shown, a kind of preparation method of lithium manganese phosphate lithium battery cathode material comprises the following steps:

[0046] A) Dissolve 18mmol of manganese sulfate in 36ml of water and stir continuously to form a manganese source solution; dissolve a total of 18mmol of phosphoric acid in 36ml of water to form a phosphorus source solution; dissolve 54mmol of lithium hydroxide in 36ml of water forming a lithium source solution;

[0047] B) Dissolve 9mmol of citric acid in 9ml of water to form a chelating agent solution, add this solution to the manganese source solution, and keep stirring evenly; then add the aqueous solution of phosphorus source to the above solution, and stir evenly, and finally Add the dissolved lithium source solution into the above mixing system and stir evenly.

[0048] C) Add 13g (accounting for 10% of the total solvent mass fraction) of high boiling point compound DMSO to the above system to...

Embodiment 2

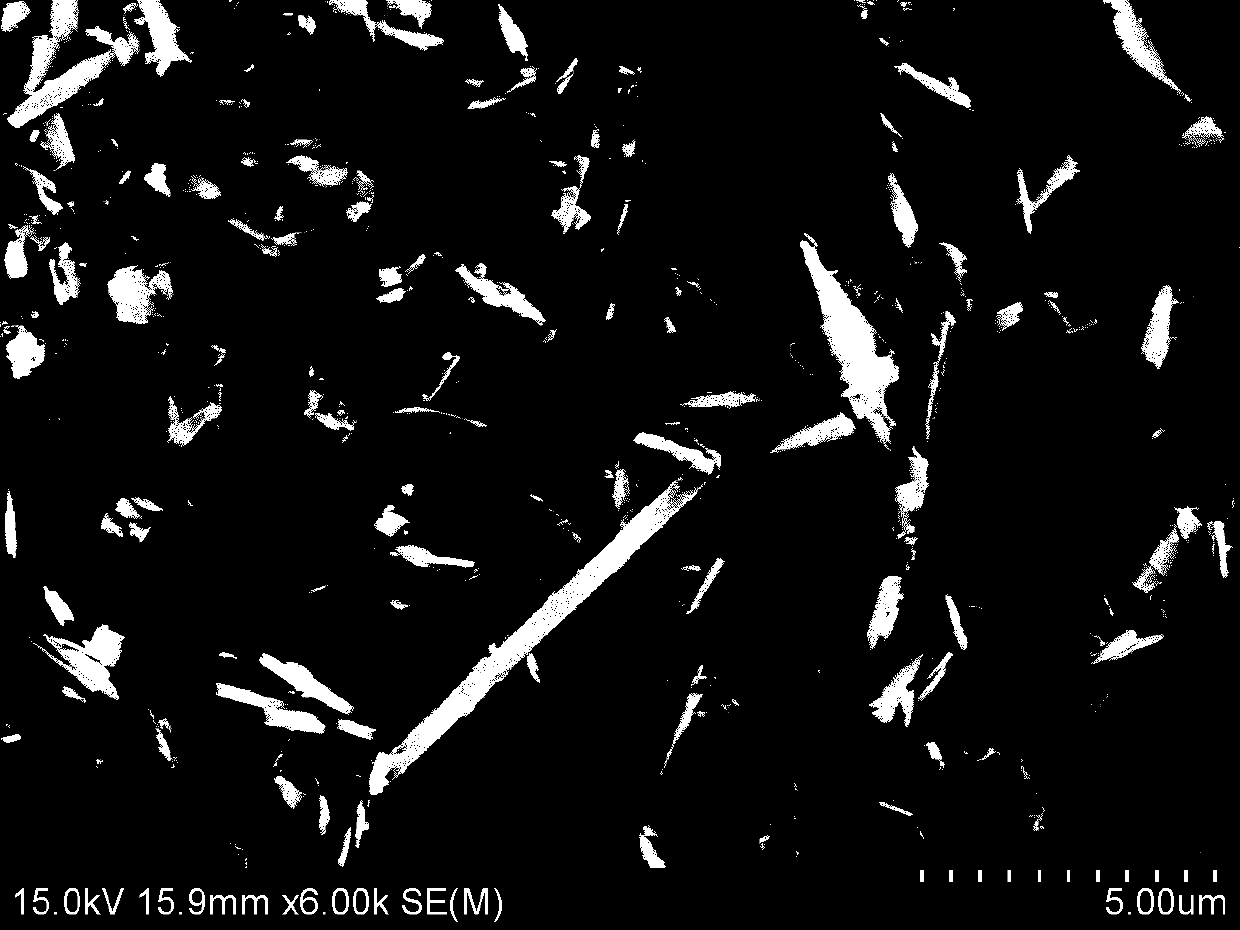

[0055] Embodiment 2: as figure 2 , Figure 4 , Image 6 , Figure 7 Shown, a kind of preparation method of lithium manganese phosphate lithium battery cathode material comprises the following steps:

[0056] A) Dissolve 18mmol of manganese sulfate in 36ml of water, stir continuously to form a manganese source solution; dissolve a total of 18mmol of phosphoric acid (12mmol) + ammonium dihydrogen phosphate (6mmol) in 36ml of water to form a phosphorus source solution; 54mmol of lithium acetate was dissolved with 36ml of water to form a lithium source solution;

[0057] B) Dissolve 9mmol of citric acid in 9ml of water to form a chelating agent solution, add this solution to the manganese source solution, and keep stirring evenly; then add the aqueous solution of phosphorus source to the above solution, and stir evenly, and finally Add the dissolved lithium source solution into the above mixing system and stir evenly.

[0058] C) Add 29.25g of high boiling point compound DMS...

Embodiment 3

[0062] Embodiment 3: as image 3 , Figure 8 Shown, a kind of preparation method of lithium manganese phosphate lithium battery cathode material comprises the following steps:

[0063] A) Dissolve 18mmol of manganese sulfate in 36ml of water, stir continuously to form a manganese source solution; dissolve a total of 18mmol of phosphoric acid (6mmol) + ammonium dihydrogen phosphate (12mmol) in 36ml of water to form a phosphorus source solution; 54mmol of lithium hydroxide was dissolved with 36ml of water to form a lithium source solution;

[0064] B) Dissolve 9mmol of citric acid in 9ml of water to form a chelating agent solution, add this solution to the manganese source solution, and keep stirring evenly; then add the aqueous solution of phosphorus source to the above solution, and stir evenly, and finally Add the dissolved lithium source solution into the above mixing system and stir evenly.

[0065] C) Add 50.1g of high-boiling point compound DMSO (accounting for 30% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com