A kind of preparation method of lithium iron manganese phosphate lithium battery cathode material

A technology of lithium iron manganese phosphate and cathode material, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. The effect of lowering the reaction energy barrier, improving the kinetic behavior, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

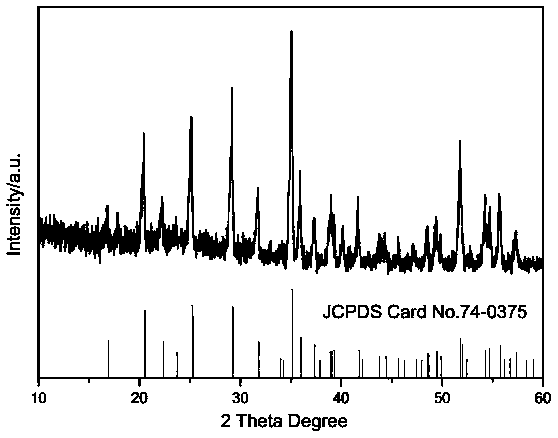

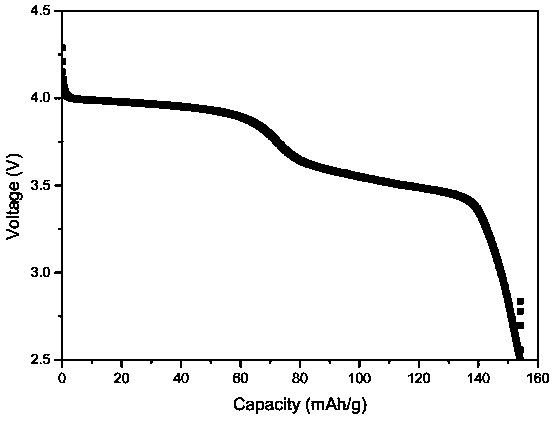

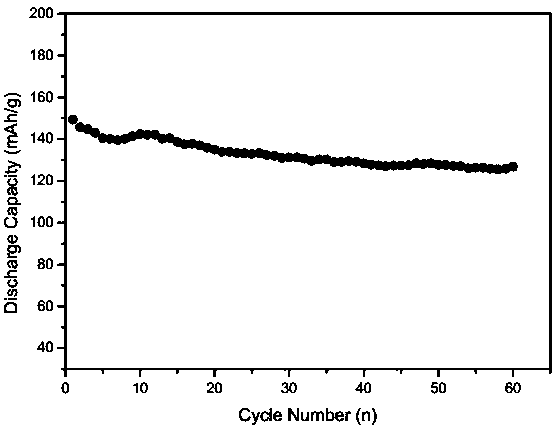

Image

Examples

Embodiment 1

[0041] Embodiment 1, a kind of preparation method of lithium iron manganese phosphate lithium battery cathode material, the method comprises the following steps:

[0042] A. Dissolve 2.282g of manganese sulfate and 1.251g of ferrous sulfate with 27ml and 9ml of water respectively to form manganese source solution and iron source solution, then mix the two and keep stirring evenly;

[0043] B. Dissolve 1.891g of citric acid in 9ml of water, add citric acid to the above solution, and keep stirring; dissolve 0.441g of phosphoric acid and 1.553g of ammonium dihydrogen phosphate with 36ml of water to form a phosphorus source solution , and added to the above solution;

[0044] C. Add 13g of high boiling point compound DMSO to the above system, and keep stirring; form a mixed solvent of DMSO and water, dissolve 2.266g of lithium hydroxide with 36ml of water to form a lithium source solution, and then add it to the above system in, and constantly stirring, after stirring evenly, tes...

Embodiment 2

[0051] Embodiment 2, a preparation method of lithium iron manganese phosphate lithium battery cathode material, the method comprises the following steps:

[0052] A. Dissolve 2.282g of manganese sulfate and 1.251g of ferrous sulfate with 27ml and 9ml of water respectively to form manganese source solution and iron source solution, then mix the two and keep stirring evenly;

[0053] B. Dissolve 1.891g of citric acid in 9ml of water, add citric acid to the above solution, and keep stirring; dissolve 2.071g of ammonium dihydrogen phosphate with 36ml of water to form a phosphorus source solution, and add it to In the above solution;

[0054] C. Add 29.25g of high boiling point compound DMSO into the above system, and keep stirring; form a mixed solvent of DMSO and water, dissolve 2.266g of lithium hydroxide with 36ml of water to form a lithium source solution, and then add it to the above system, and keep stirring, after stirring evenly, test the pH value of the solution, and adj...

Embodiment 3

[0060] Embodiment 3, a preparation method of lithium iron manganese phosphate lithium battery cathode material, the method comprises the following steps:

[0061] A. Dissolve 2.282g of manganese sulfate and 1.251g of ferrous sulfate with 27ml and 9ml of water respectively to form manganese source solution and iron source solution, then mix the two and keep stirring evenly;

[0062] B. Dissolve 1.891g of citric acid in 9ml of water, add citric acid to the above solution, and keep stirring; dissolve 2.071g of ammonium dihydrogen phosphate with 36ml of water to form a phosphorus source solution, and add it to In the above solution;

[0063] C. Add 50.14g of high boiling point compound DMSO to the above system, and keep stirring; form a mixed solvent of DMSO and water, dissolve 2.266g of lithium hydroxide with 36ml of water to form a lithium source solution, and then add it to the above system, and keep stirring, after stirring evenly, test the pH value of the solution, and adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com