Spiral centrifugal fan and air treatment device

A centrifugal fan and spiral technology, applied in mechanical equipment, non-displacement pumps, non-variable volume pumps, etc., can solve the problems of low air pressure, large air volume, and large volume, and achieve high air pressure, large air volume, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

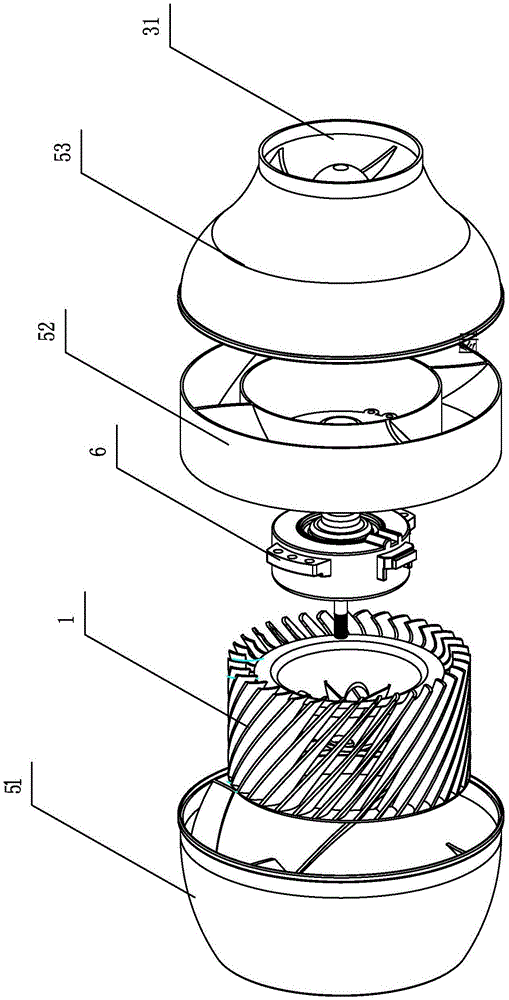

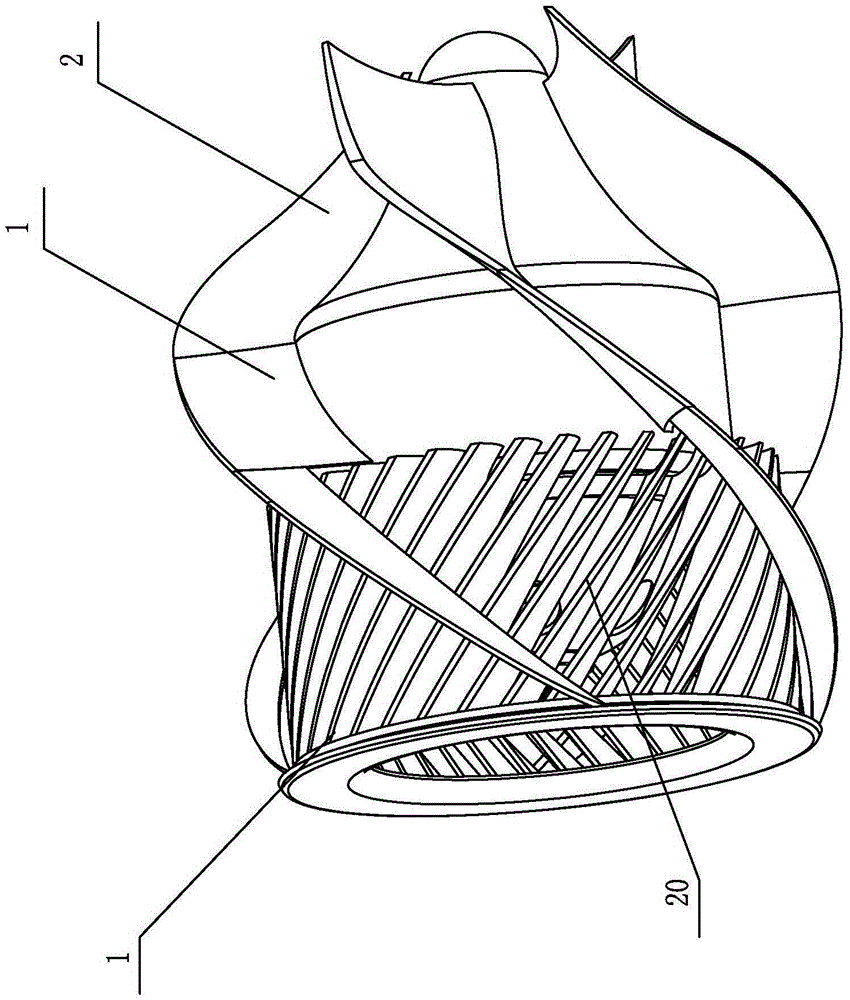

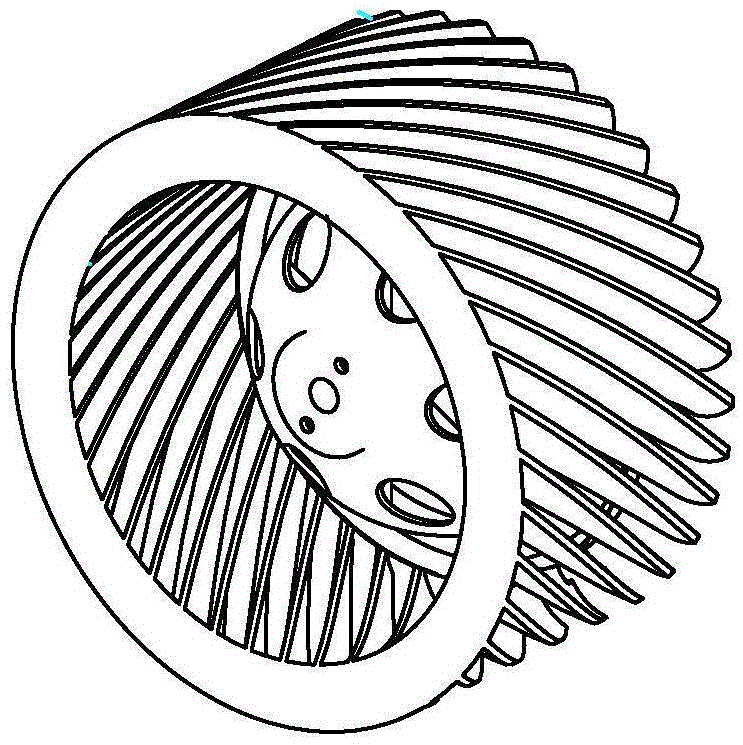

[0030] Embodiment 1, with reference to attached figure 1 , 2 , 3, 3a, 4, 4a, 5a, 5b, 5c, 8.

[0031] The spiral centrifugal fan provided by the present invention includes a motor 6 , a centrifugal rotor 1 and a centrifugal rotor housing 3 , and the motor 6 drives the centrifugal rotor 1 to rotate. The centrifugal wind wheel 1 is located at the center of the centrifugal wind wheel shell; the inner wall of the centrifugal wind wheel shell is provided with more than one spiral air duct (for example, 5 in this embodiment), and the spiral air duct is in the On the periphery of the centrifugal wind wheel 1, its air inlet 20 is located on the radially outer side of the centrifugal wind wheel 1. The blades 10 of the centrifugal wind wheel are inclined to the rotation axis of the centrifugal wind wheel, and the wind discharged by the wind blades 10 can smoothly enter the spiral The air channel 2 avoids hitting the wall of the air channel as much as possible. The spiral air channel gu...

Embodiment 2

[0039] Embodiment 2, with reference to attached Figure 6 , 7 ,8.

[0040] In this embodiment, the snail shape is an involute snail shape, and reference numeral 53b is the front end section of the casing of the centrifugal fan. Other parts of this embodiment are the same as Embodiment 1, in Figure 6 , 7 , 8 reference numbers and figure 1 , 2 , 3, 3a, 4, 4a, 5a, 5b, and 5c represent the same meaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com