Automatic measurement method for backlash of bevel gear pair of steering gear

A technology of bevel gear pairs and measurement methods, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of low measurement accuracy and measurement efficiency, and achieve the effect of reducing repeated matching work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

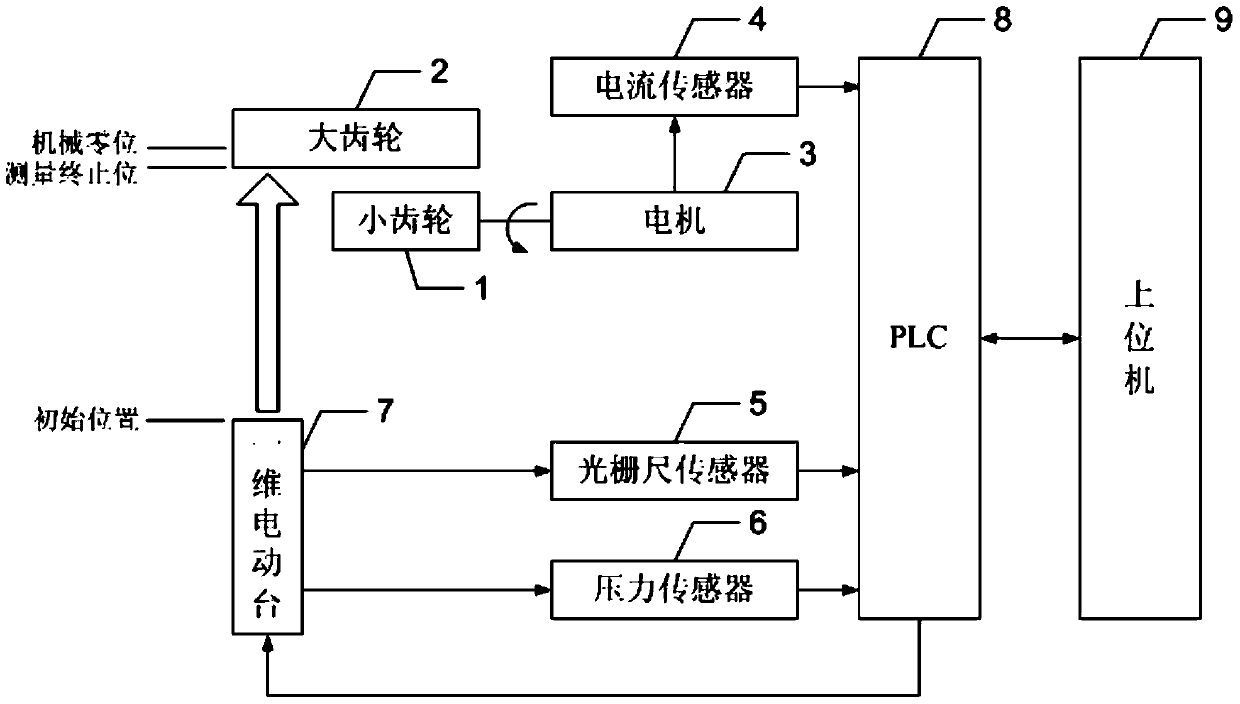

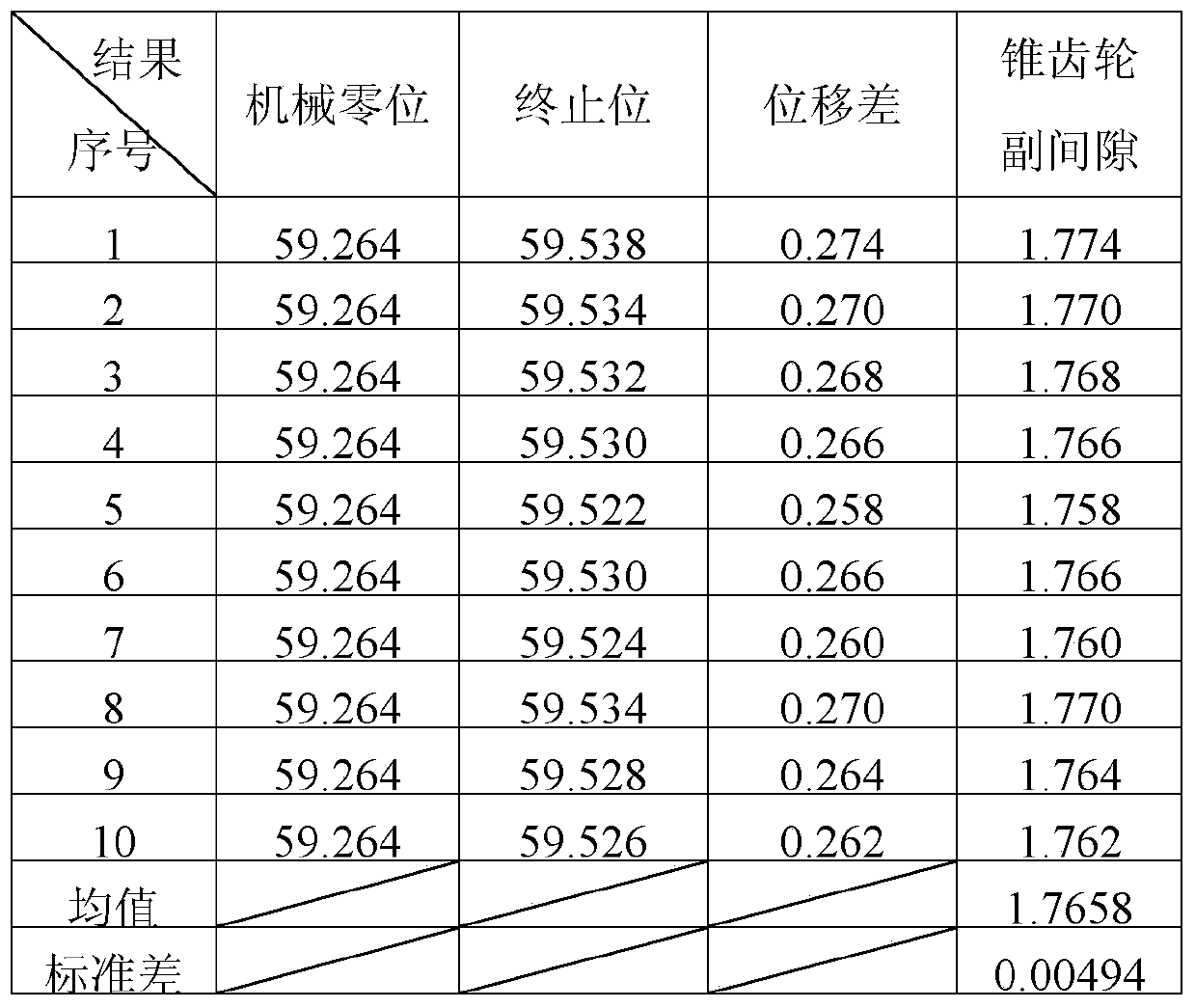

[0024] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the steering gear bevel gear pair gap automatic measurement method described in this embodiment, the measuring tool of this method includes motor 3, current sensor 4, grating scale sensor 5, pressure sensor 6 and one-dimensional electric platform 7;

[0025] The bevel gear pair includes a pinion 1 and a bull gear 2, the pinion 1 is driven to rotate by the motor 3, and the bull gear 2 in the working state meshes with the pinion 1 for transmission;

[0026] A grating ruler sensor 5 and a pressure sensor 6 are arranged on the one-dimensional electric stage 7; the grating ruler sensor 5 is used to measure the moving distance of the one-dimensional electric stage 7, and the pressure sensor 6 is used to measure the distance between the one-dimensional electric stage 7 and the large gear 2 The pressure; the current sensor 4 is used to monitor the current value of the motor 3; the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com