Integrated circuit manufacturing methods

A technology of integrated circuit and manufacturing method, which is applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

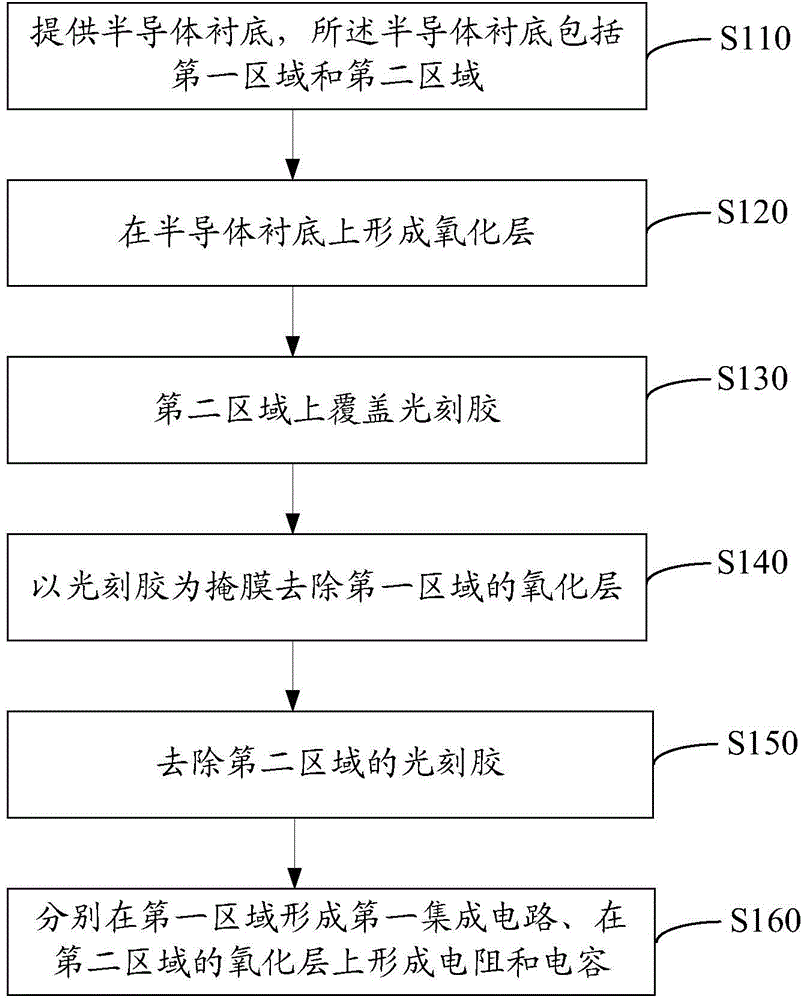

[0078] The present invention provides three different integrated circuit manufacturing methods, which will be described below in conjunction with specific drawings and corresponding embodiments.

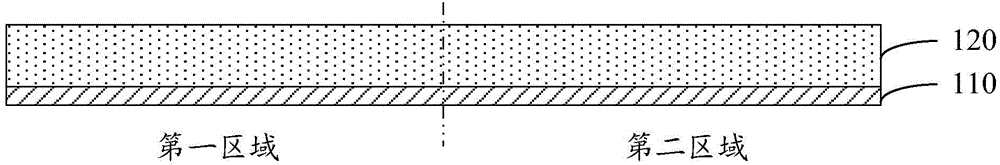

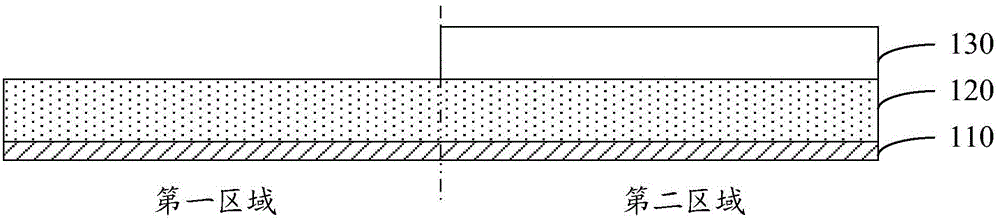

[0079] Please refer to figure 1 and Figure 2-7 , is a flowchart of the first integrated circuit manufacturing method in an embodiment and a schematic diagram of corresponding effects.

[0080] Step S110: providing a semiconductor substrate, the semiconductor substrate including a first region and a second region.

[0081] In this embodiment, the semiconductor substrate 110 can be either N-type or P-type. The first area here is used to form the first integrated circuit, and the voltage capability of the first integrated circuit is below 250 volts, so the first area is also called the medium and low voltage area, and the first integrated circuit is also called the medium and low voltage integrated circuit. The second area here is used to form resistors and capacitors, which can wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap