Enhanced digital-light-processing mask exposure rapid prototyping method and apparatus

A technology of digital light processing and surface exposure, which can be used in processing data acquisition/processing, manufacturing auxiliary devices, image reproducers using projection devices, etc. , Overcome the effect of edge distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

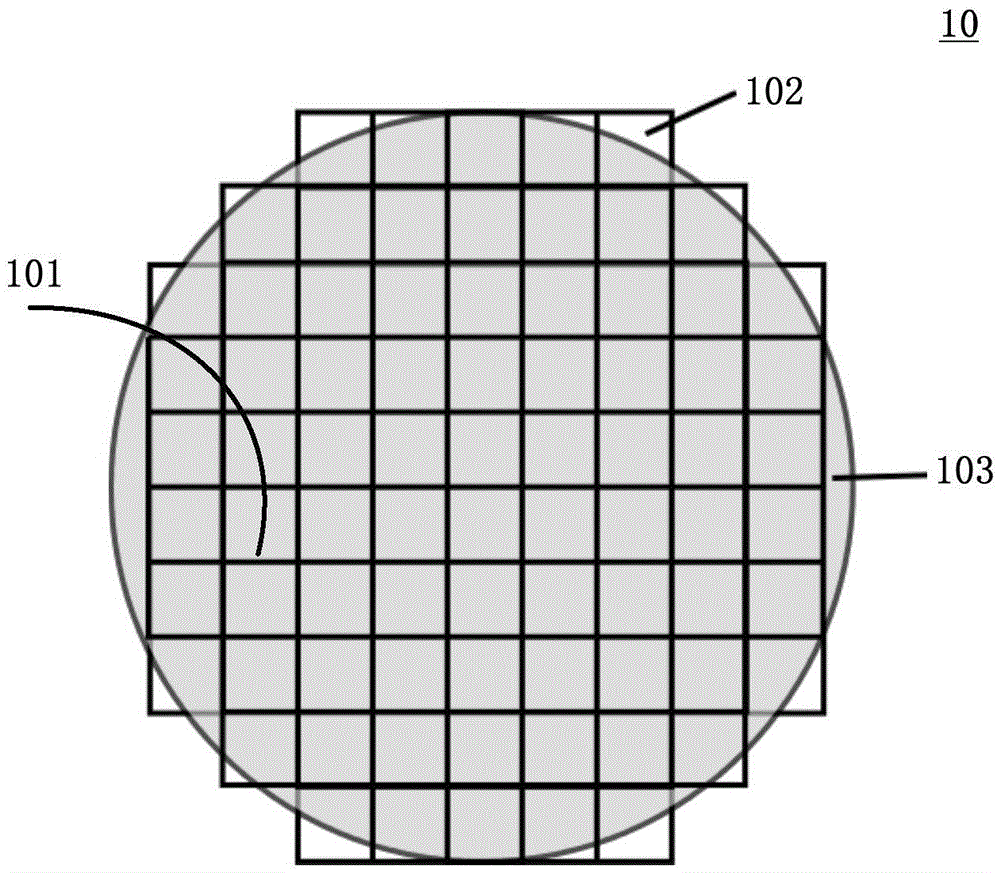

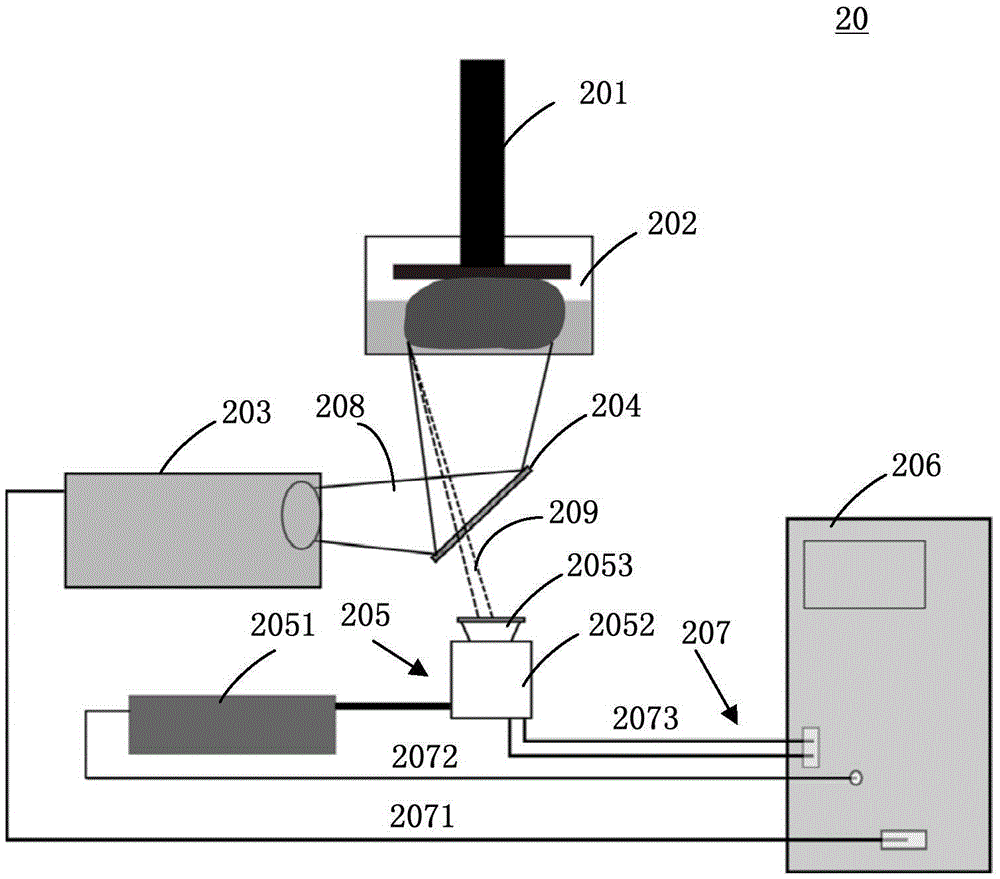

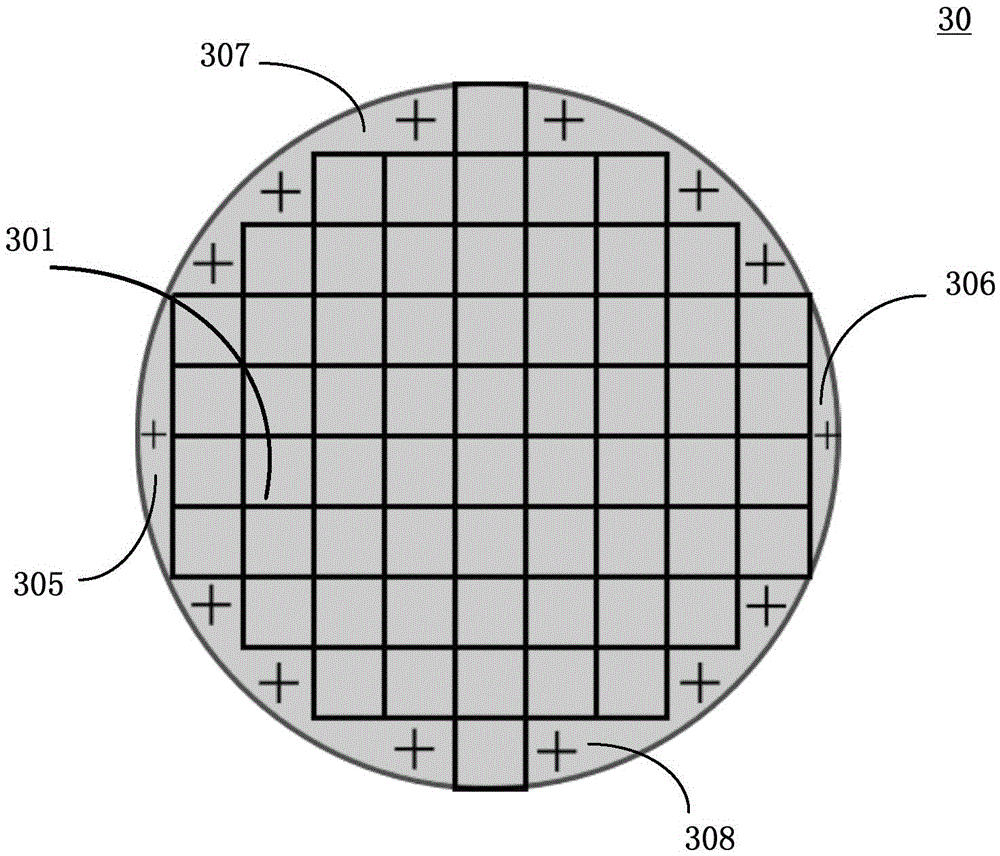

[0025] The present invention proposes a method for enhanced digital light processing surface exposure rapid prototyping, which includes the following steps: layering the model of the molded object, and bitmapping the layer, and then dividing the bitmap of the layer into a main body area and The boundary filling area; the main body area in the bitmap corresponding to the layer of the object formed by the digital light processing unit; and the boundary filling area in the bitmap corresponding to the layer of the object formed by the laser marking unit. Preferably, the shaping of the main body area by the digital light processing unit and the shaping of the boundary filling area by the laser marking unit are performed simultaneously. Preferably, the boundary filling area in the bitmap corresponding to the slice layer of the object is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com